Nanometer Ni-P conductive ink and preparation method thereof

A conductive ink and nano technology, applied in the field of nano materials, can solve the problems of high activity of nano copper powder, high economic cost and high price, and achieve the effects of high economic and practical value, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dissolve 6.5375g of nickel sulfate hexahydrate and 7.5g of sodium hypophosphite in 50ml of deionized water, stir, mix with a 250ml volumetric flask to constant volume, cool, keep warm at 20°C, add 4ml of 1mol / L sodium hydroxide solution to adjust pH; slowly add 0.025g sodium borohydride, 0.033g hydrazine hydrate, 0.1429g potassium borohydride, continue to stir for 60 minutes, cool to room temperature, and age for 6 hours to obtain a Ni-P nano-nickel powder dispersion; the obtained dispersion Centrifuge at a speed of 6000 rpm for 30 minutes, wash twice with ammonia water, deionized water and absolute ethanol, and then vacuum-dry at room temperature for 3 hours to obtain Ni-P nano-nickel powder; weigh 0.2 g of nano-nickel powder, dissolved in 0.5g ethylene glycol solvent, and added 0.3g dispersant-polyethylene glycol, to obtain 20% nanometer Ni-P conductive ink.

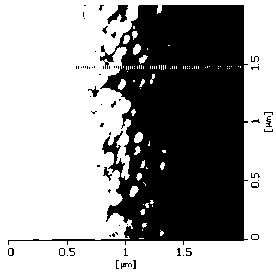

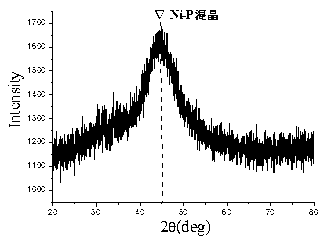

[0039] The Ni-P nano-nickel powder obtained above is sampled, and its phase spectrum analysis is carried out ...

Embodiment 2

[0042] Dissolve 3.2234g of nickel chloride and 7.5g of sodium hypophosphite in 50ml of deionized water, stir, mix with a 250ml volumetric flask to constant volume, cool, keep warm at 40°C, add 4ml of 1mol / L sodium hydroxide solution to adjust the pH Slowly add 0.066g hydrazine hydrate, keep stirring for 40 minutes, cool to room temperature, and age for 6 hours to obtain a Ni-P nano-nickel powder dispersion; the dispersion obtained is centrifuged at a speed of 6000 rpm for 30 minutes, Wash twice with ammonia water, deionized water and absolute ethanol respectively, then vacuum-dry at room temperature for 3 hours to obtain Ni-P nano-nickel powder; weigh 0.3g nano-nickel powder, dissolve in 0.6g ethylene glycol solvent, and Add 0.1g dispersant oleic acid to obtain 30% nano Ni-P conductive ink.

[0043] The Ni-P nano-nickel powder obtained above was sampled, and it was analyzed by X-ray diffractometer (XRD), and the results were as follows: Figure 5 . Sampling the Ni-P conducti...

Embodiment 3

[0046]Dissolve 3.2686g of nickel sulfate hexahydrate, 1.6117g of nickel chloride and 7.5g of sodium hypophosphite in 50ml of deionized water, stir, mix with a 250ml volumetric flask to volume, cool, transfer to a beaker and heat to 40°C, add 4 milliliters of 1mol / L sodium hydroxide solution adjusts pH; Slowly add 0.066g hydrazine hydrate, keep stirring for 60 minutes, cool to room temperature, and age for 6 hours to obtain a Ni-P nano-nickel powder dispersion; Centrifuge for 15 minutes under the rotating speed of rev / min, wash twice with ammoniacal liquor, deionized water and absolute ethanol respectively, then vacuum-dry at room temperature for 3 hours, obtain Ni-P nano-nickel powder; Weigh 0.3g nano-nickel powder, Dissolve in 0.5g ethanol solvent, and add 0.2g OP-10 emulsifier to obtain 30% nano Ni-P conductive ink.

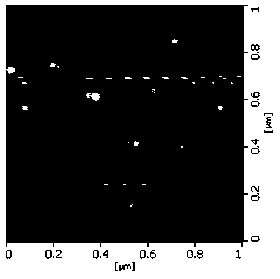

[0047] Sampling the Ni-P conductive ink, using an atomic force microscope (AFM) to observe the nano-nickel powder in the nano-Ni-P conductive ink, the results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com