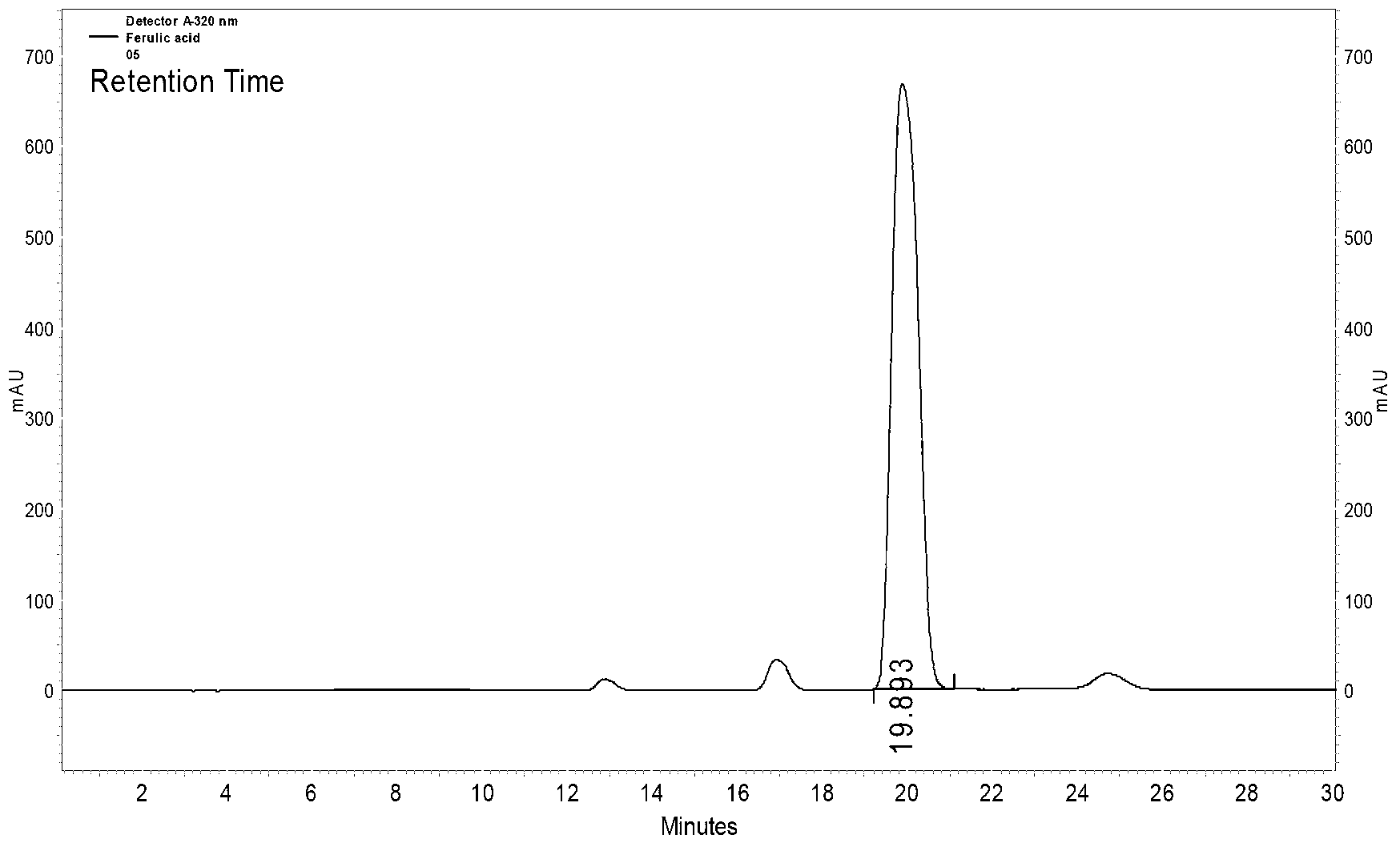

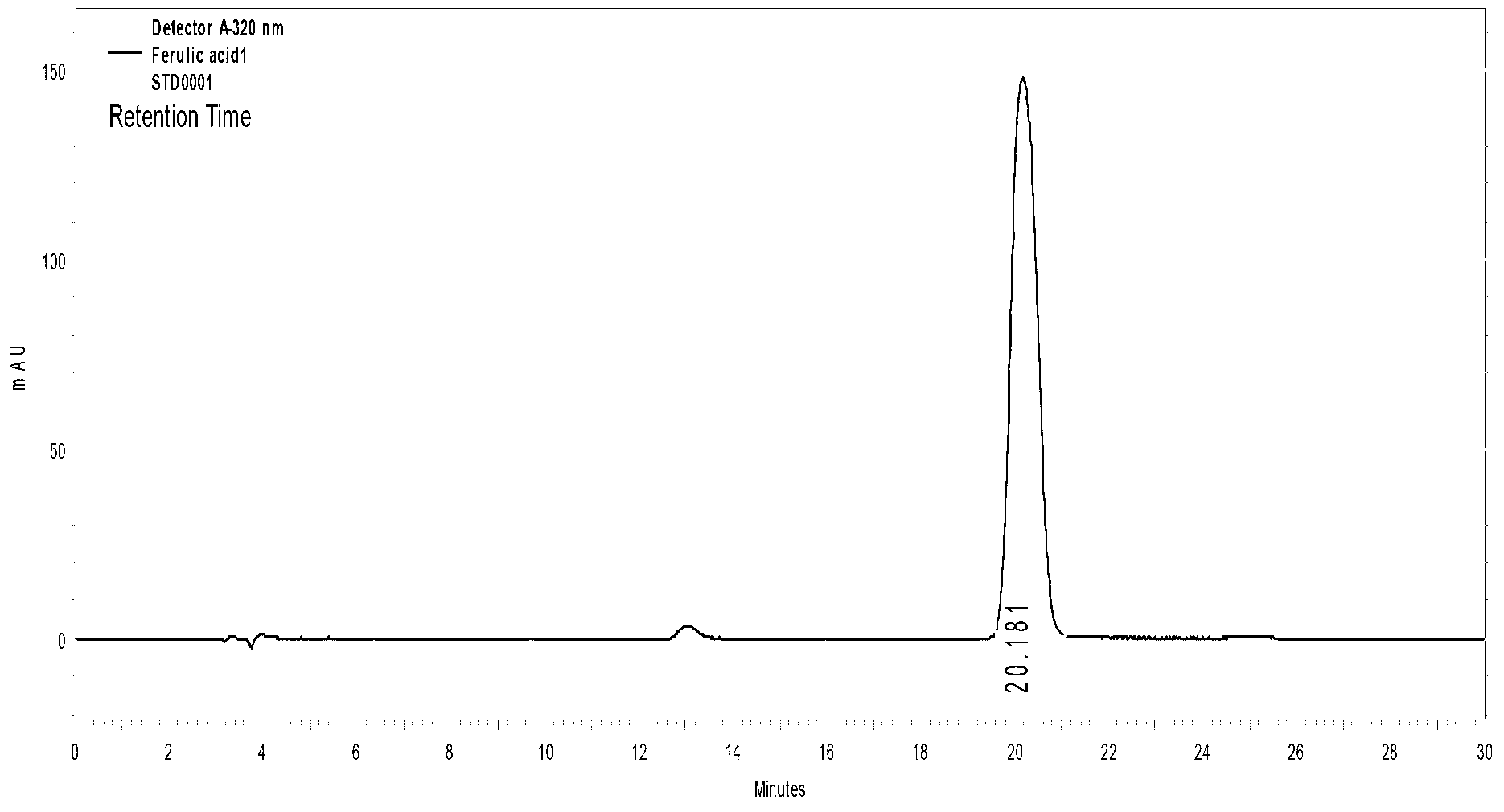

Preparation method for ferulic acid

A technology for ferulic acid and cellulosic raw materials, applied in the preparation of organic compounds, chemical instruments and methods, preparation of oxygenated compounds, etc., to achieve mild conditions, reduced costs and pollution, and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: utilize corn bran to prepare ferulic acid

[0036] (1) Pretreatment of raw materials:

[0037] Take a certain amount of corn husks, dry them at 105°C until the water content is 5%, grind them through a 40-mesh sieve with a grinder, and obtain the pretreated raw materials.

[0038] (2) Alkali alcohol treatment to obtain crude ferulic acid:

[0039] The raw material pretreated in step (1) is mixed with a solid-to-liquid ratio of 1 kg: 10 liters and a 2:50:50 (w / v / v) aqueous alkali alcohol solution (a mixed solution of sodium hydroxide: ethanol: water), 80 Extract at ℃ for 2.5 hours, centrifuge and filter in a three-legged centrifuge, and the filter residue can be used to prepare oligosaccharides;

[0040] The obtained filtrate is subjected to ultrafiltration with a membrane with a molecular weight cut-off of 5000 to further remove soluble macromolecular substances, and the permeate is used for future use.

[0041] (3) Obtaining ferulic acid:

[0042] The...

Embodiment 2

[0043] Embodiment 2: utilize wheat bran to prepare ferulic acid

[0044] (1) Pretreatment of raw materials:

[0045] Take a certain amount of wheat bran, dry it at 105°C to a water content of 2%, and pulverize it with a pulverizer (the degree of pulverization is 60 mesh) to obtain the pretreated raw material.

[0046] (2) Alkali alcohol treatment to obtain crude ferulic acid:

[0047] The raw material pretreated in step (1) is mixed with a solid-to-liquid ratio of 1 kg: 15 liters and a 3:60:40 (w / v / v) aqueous alkali alcohol solution (mixed solution of potassium hydroxide: ethanol: water), 60 Extract at ℃ for 4 hours and centrifuge in a three-legged centrifuge.

[0048] The centrifugate is further removed by ultrafiltration equipment with a membrane molecular weight cut-off of 10,000 and 2,000, and the permeate is used for standby.

[0049] (3) Obtaining high-purity ferulic acid:

[0050] The permeate in step (2) is subjected to nanofiltration treatment. The treatment step...

Embodiment 3

[0051] Embodiment 3: utilize bagasse to prepare ferulic acid

[0052] (1) Pretreatment of raw materials:

[0053] Take a certain amount of bagasse and grind it through a pulverizer (the degree of crushing is 20 mesh), and then dry it at 105°C until the water content is 5%.

[0054] (2) Alkali alcohol treatment to obtain crude ferulic acid:

[0055]The raw material pretreated in step (1) is mixed with a solid-to-liquid ratio of 1 kg: 12 liters and a 4:70:30 (w / v / v) alkali alcohol aqueous solution (sodium hydroxide: ethanol: water mixed solution), continuously Stir, extract at 40°C for 7 hours, and centrifuge in a three-legged centrifuge.

[0056] The centrifugate is further removed by ultrafiltration equipment with a membrane molecular weight cut-off of 20,000 and 1,000, and the permeate is used for standby.

[0057] (3) Obtaining ferulic acid:

[0058] The permeate in step (2) is subjected to nanofiltration treatment. The treatment steps of the permeate with nanofiltratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com