Crystallization method of cyclic adenosine monophosphate

A technology for cyclic adenosine monophosphate and cyclic adenosine monophosphate sodium salt is applied in the crystallization field of cyclic adenosine monophosphate, which can solve the problems of inconvenient storage, transportation and use, low water content of amorphous products, poor particle size distribution and crystal habit quality, etc. , to achieve the effect of easy industrialized continuous production, good gloss and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 500g of anion exchange resin to fill the fixed bed. After equilibrium, put 10L of cAMP fermentation broth with a concentration of about 5.31g / L on the column. After the adsorption is saturated, use high-concentration NaCl and a small amount of hydrochloric acid to elute to obtain high-concentration cyclic adenosine monophosphate. Sodium saline solution.

Embodiment 2

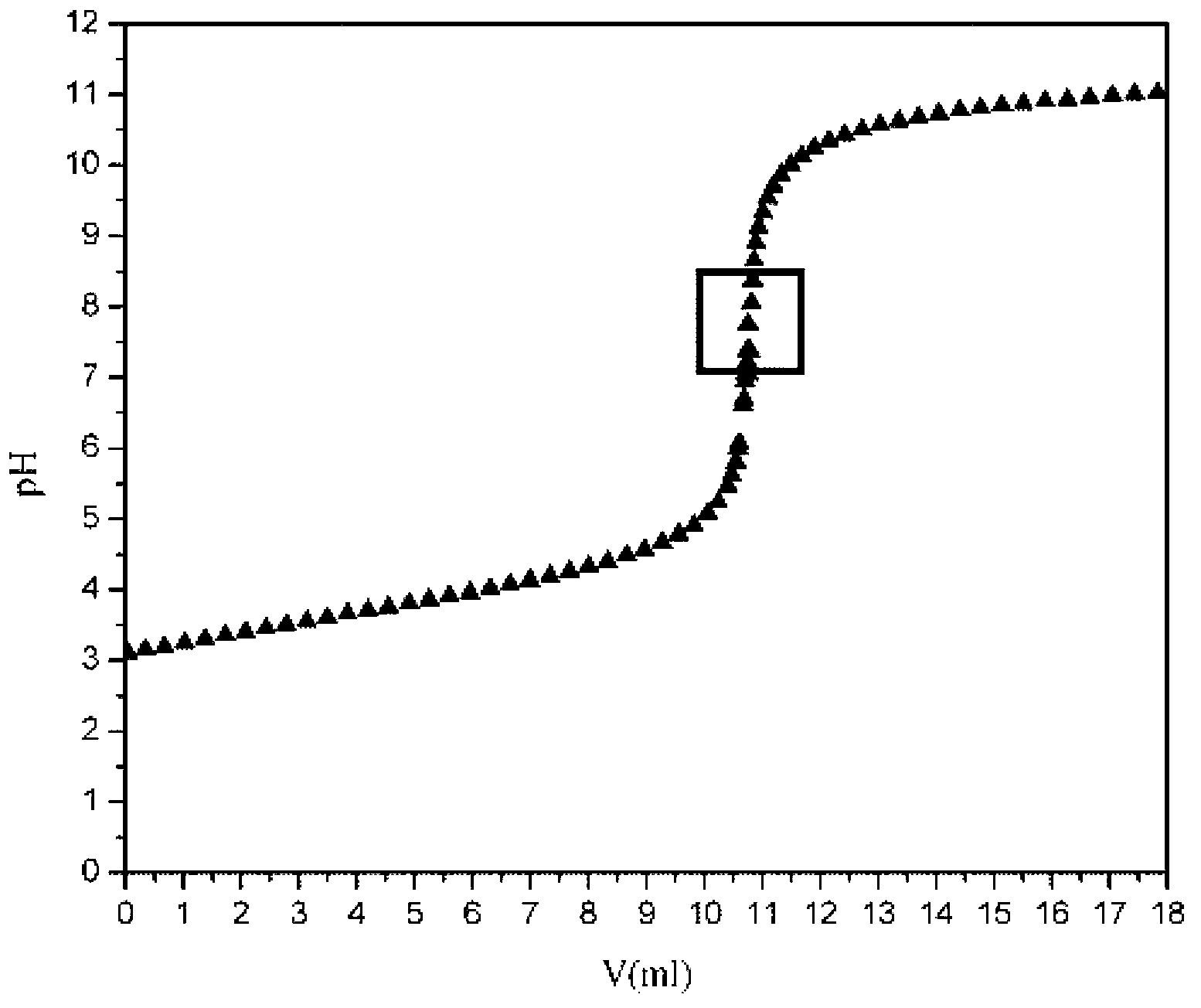

[0031] Take 10ml of cyclic adenosine monophosphate aqueous solution with a concentration of 4g / L, pH=3.01, titrate with 0.01mol / L NaOH solution, the titration result is figure 1 . The marked part is the EP point, which is about pH=8.0.

Embodiment 3

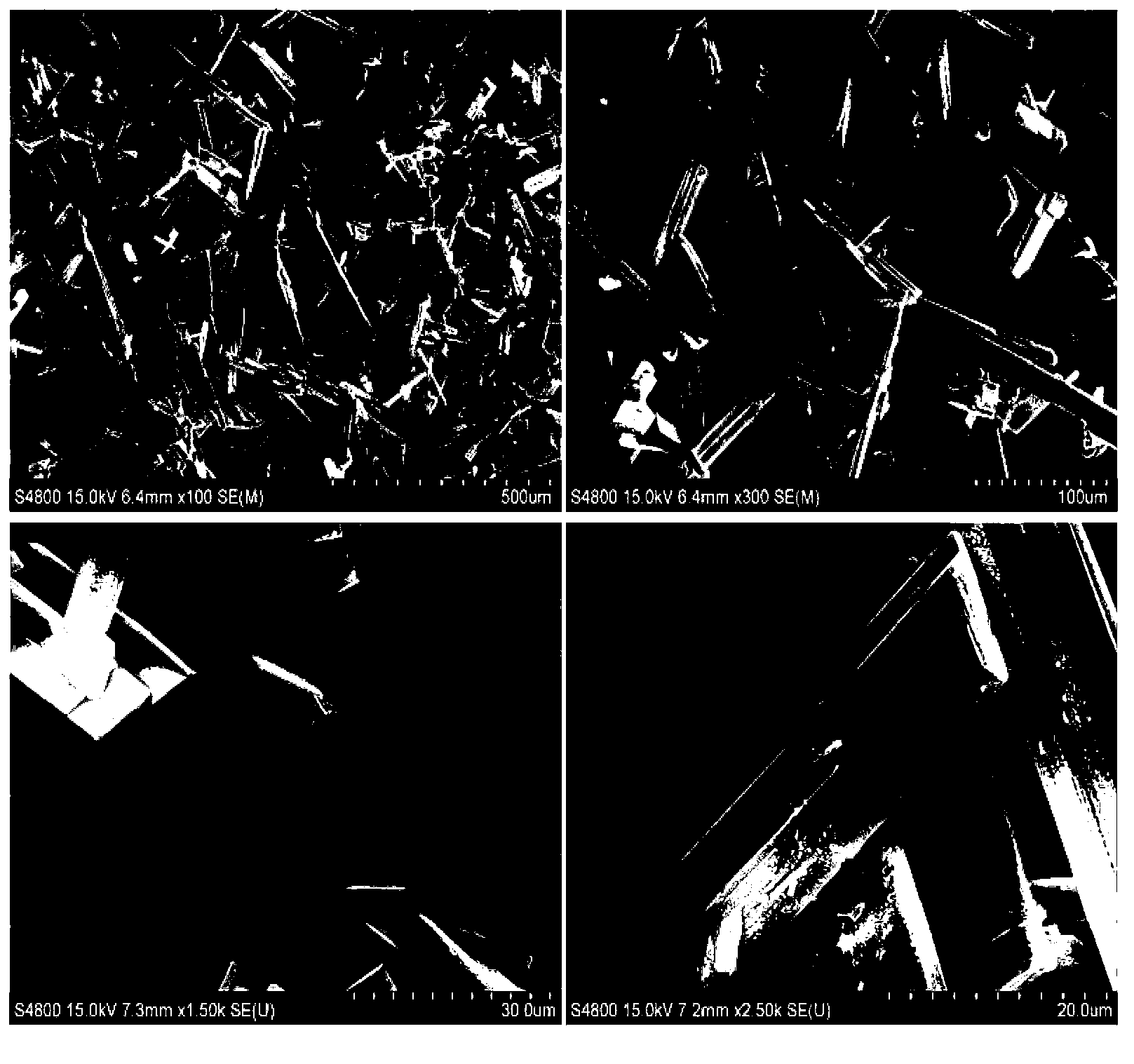

[0033] Add 10L of an aqueous solution with a concentration of 10g / L cyclic adenosine monophosphate sodium salt, pH=8.9, in a water bath controlled at 20°C and a stirring rate of 150rpm, and slowly add 29L of anti-solvent anhydrous ethanol. After the crystallization was complete, the suspension was filtered with suction, washed with a small amount of ethanol to obtain white crystals, and placed in an oven at 45°C for vacuum drying. The single-step crystallization yield was 95.1%, and the purity was 99.1%.

[0034] Take the high-purity cyclic adenosine monophosphate sodium salt that has been crystallized above to prepare 1L of saturated aqueous solution. The water bath is controlled at 20°C and the stirring rate is 120rpm. Slowly add hydrochloric acid to adjust the pH to 4.8. When tiny crystals appear, stop adding Hydrochloric acid, crystal growth at 120rpm stirring speed for 3 hours, continue to drop hydrochloric acid until the pH is 2.0, after the crystallization is complete, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com