Preparation method of titanium dioxide nanotube array photoelectrode for removing organic pollutants

A nanotube array, organic pollutant technology, applied in water pollutants, chemical instruments and methods, oxidized water/sewage treatment, etc. Low rate and other problems, to achieve good removal effect, improve photocatalytic activity, avoid the use of toxic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

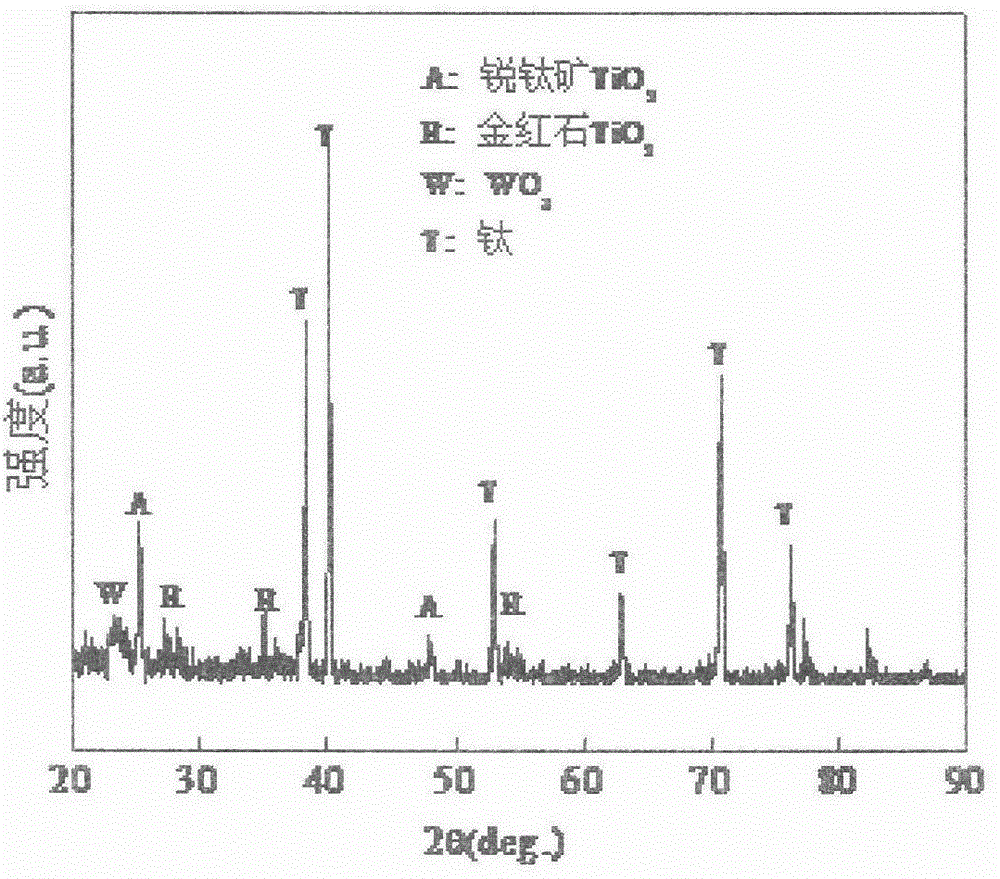

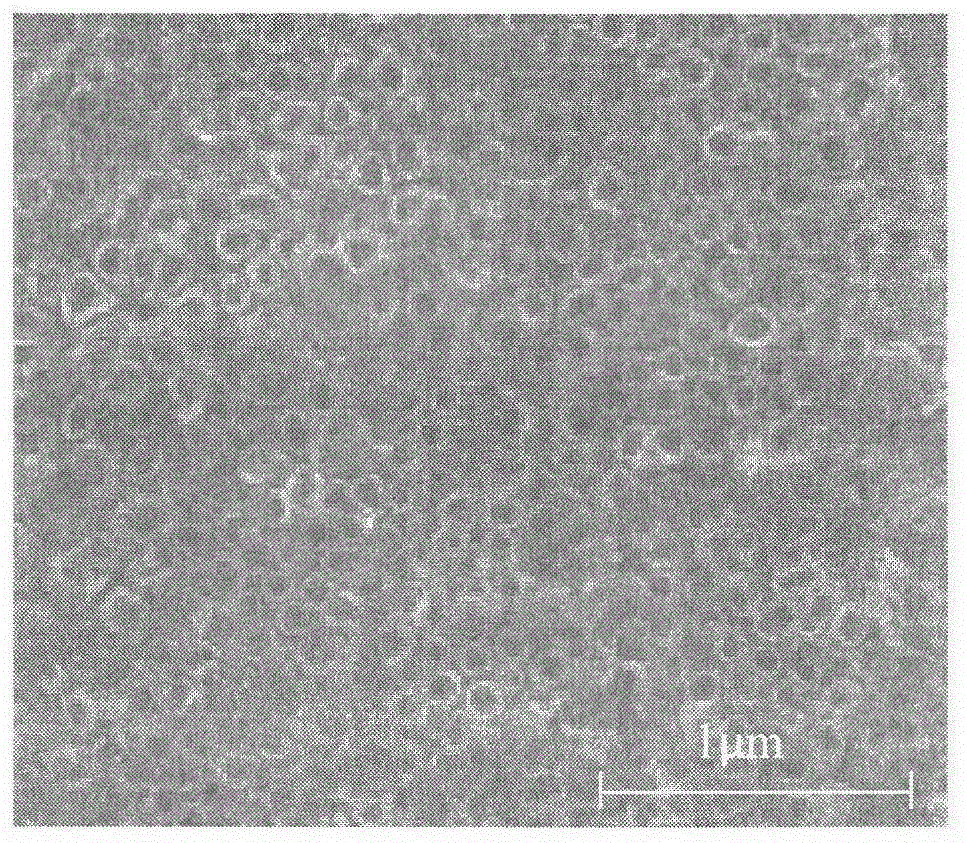

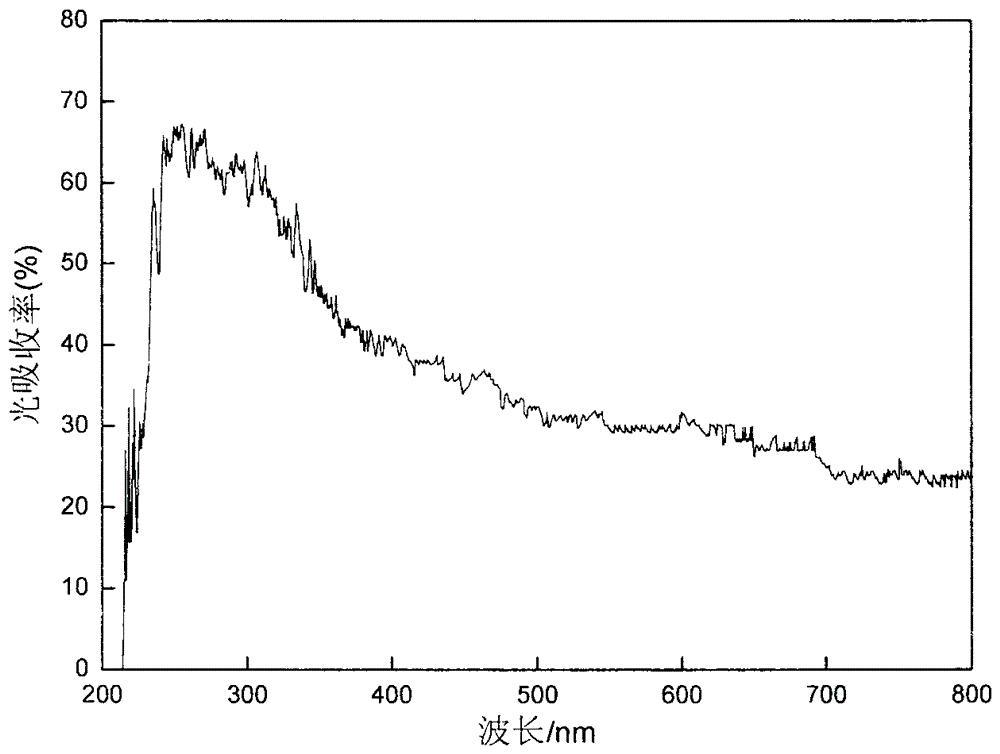

[0025] Such as figure 1 , 2 , 3, 4, and 5 show a method for preparing a titanium dioxide nanotube array photoelectrode for removing organic pollutants, the steps comprising:

[0026] 1) Cut tungsten-containing titanium sheets (tungsten90%) into strip-shaped foils of 100×10×0.2mm, and then wash them with decontamination powder and hydrofluoric acid, 1000-mesh sandpaper, 2000-mesh sandpaper Grinding and polishing, ultrasonic cleaning in acetone, ethanol and deionized water for 5 minutes;

[0027] 2) Using the tungsten-containing titanium sheet pretreated in 1) as the raw material, the tungsten trioxide-titanium dioxide nanotube array is prepared in situ by a one-step constant current and constant voltage anodization method, and the electrolyte is 0.5% NaF and 1.0M Na 2 SO 4 Mixed solution, the temperature is 25°C, the voltage is 20V, and the initial current is set to 0.005mA / cm 2 , oxidized for 2 hours, in situ generating nanotube arrays on the surface of tungsten-containing...

Embodiment 2

[0033] 1) Cut tungsten-containing titanium sheets (tungsten90%) into strip-shaped foils of 100×10×0.2mm, and then wash them with decontamination powder and hydrofluoric acid, 1000-mesh sandpaper, 2000-mesh sandpaper Grinding and polishing, ultrasonic cleaning in acetone, ethanol and deionized water for 5 min respectively.

[0034] 2) Using the tungsten-containing titanium sheet pretreated in 1) as the substrate, the tungsten trioxide-titanium dioxide nanotube array was prepared in situ by a one-step constant current and constant voltage anodization method, and the electrolyte was 0.4% NaF and 0.5M Na 2 SO 4 Mixed solution, the temperature is 25°C, the voltage is 20V, and the initial current is set to 0.004mA / cm 2 , oxidized for 2h, in situ generating nanotube arrays on the surface of tungsten-containing titanium sheet.

[0035] 3) The nanotube array prepared in step 2) was calcined at 450° C. for 2 hours, cooled in the furnace and then used for later use.

[0036] 4) With g...

Embodiment 3

[0041] 1) Cut tungsten-containing titanium sheets (tungsten90%) into strip-shaped foils of 100×10×0.2mm, and then wash them with decontamination powder and hydrofluoric acid, 1000-mesh sandpaper, 2000-mesh sandpaper Grinding and polishing, ultrasonic cleaning in acetone, ethanol and deionized water for 5 min respectively.

[0042] 2) With the tungsten-containing titanium sheet pretreated in 1) as the substrate, the tungsten trioxide-titanium dioxide nanotube array was prepared in situ by a one-step constant current and constant voltage anodization method, and the electrolyte was 0.5% NaF and 0.8M Na 2 SO 4 Mixed solution, the temperature is 25°C, the voltage is 20V, and the initial current is set to 0.002mA / cm 2 , oxidized for 2h, in situ generating nanotube arrays on the surface of tungsten-containing titanium sheet.

[0043] 3) The nanotube array prepared in step 2) was calcined at 750° C. for 2 hours, cooled in the furnace and then used for later use.

[0044] 4) With gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com