Preparation method for flexible polycrystalline silicon carbide micro-nanofiber mat

A technology of micro-nano fiber and silicon carbide, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of unusable, high temperature resistance not exceeding 1000 °C, etc., and achieve small diameter and easy processing and use , The effect of mild spinning conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

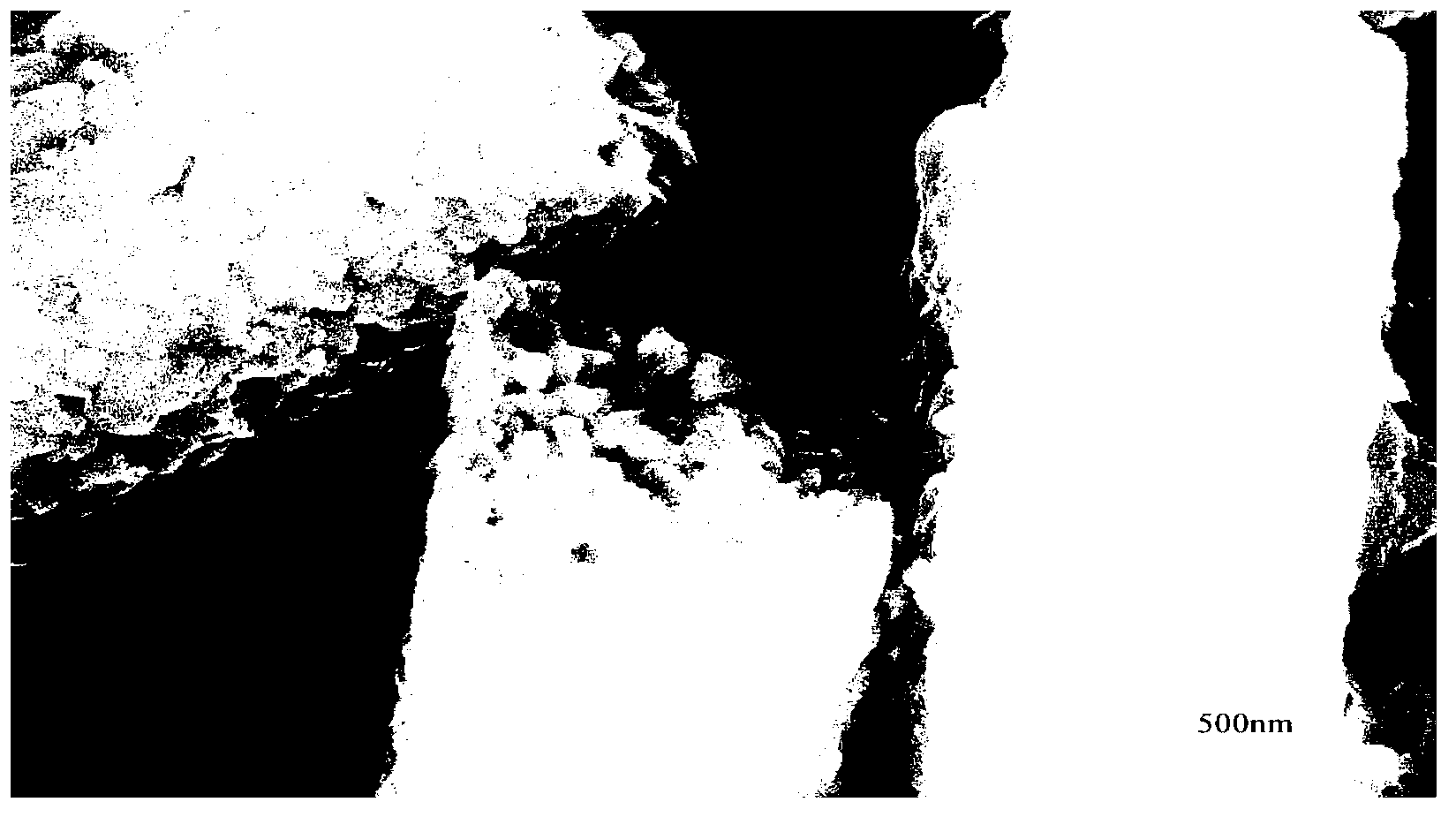

[0021] Mixed solvents of xylene, tetrahydrofuran and dimethylformamide were prepared at a volume ratio of 3:1:1. Add 5.0 g of polyaluminocarbosilane into 5.0 mL of the mixed solvent and stir thoroughly for 6 h to obtain a polyaluminocarbosilane solution with a concentration of 1.0 g / mL. After filling the solution into a glass syringe, the spinneret is an 8# metal needle, and the output voltage is 20kV, the injection flow rate is 2.0mL / h, and the roller acceptance distance is 8cm, and the electrospinning is carried out at room temperature. After spinning for 2 hours The polyaluminocarbosilane fiber felt was obtained; then dried at 50°C for 2 hours, heated to 200°C in air for 2 hours to cross-link, and finally pyrolyzed and sintered at 1800°C for 20 minutes in a high-purity nitrogen atmosphere to obtain a flexible multi- Crystalline silicon carbide micro-nano fiber mat, the fiber diameter is uniformly distributed around 1.5μm. The physical picture of the flexible polyaluminocar...

Embodiment 2

[0023] Prepare a mixed solvent of xylene and dimethylformamide at a volume ratio of 7:3. Add 4.5 g of polyaluminocarbosilane into 5 mL of the mixed solvent and stir thoroughly for 4 h to obtain a polyaluminocarbosilane solution with a concentration of 0.9 g / mL. After putting the solution into a glass syringe, the spinneret was a 8# metal needle, and the electrospinning was carried out at an output voltage of 20kV, an injection flow rate of 2.0mL / h, a flat aluminum foil collection distance of 10cm, and room temperature. After spinning for 3 hours, poly Aluminocarbosilane fiber felt; then, dry the fiber felt at 50°C for 2 hours, heat it up to 180°C in the air for 3 hours to cross-link; finally carry out pyrolysis and sintering treatment at 1750°C for 30 minutes in a high-purity nitrogen atmosphere to obtain a flexible multi- Crystalline silicon carbide micro-nano fiber mat.

Embodiment 3

[0025] Prepare a mixed solvent of toluene, acetone and ethanol at a volume ratio of 3:1:1. Weigh 6.0 g of polyborocarbosilane and add it into 5.0 mL of mixed solvent and stir thoroughly for 6 h to obtain a polyborocarbosilane solution with a concentration of 1.2 g / mL. After putting the solution into a glass syringe, the spinneret is a 12# metal needle, and the output voltage is 25kV, the injection flow rate is 2.0mL / h, and the receiving distance of the drum is 12cm, and the electrospinning is carried out at room temperature, and the spinning is 2.5h Finally, the polyborocarbosilane fiber felt is obtained; then it is dried at 50°C for 2 hours, heated to 200°C in air for 2 hours for cross-linking, and finally pyrolyzed and sintered at 1800°C for 30 minutes in a high-purity nitrogen atmosphere to obtain a flexible fiber mat. Polycrystalline silicon carbide micro-nano fiber mat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com