Extraction method of high-purity chlorogenic acid

An extraction method and technology of chlorogenic acid, which are applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., can solve the problems affecting the economic development value of chlorogenic acid products, and the instability of chlorogenic acid extraction and purification processes , Increase production energy consumption and cost, etc., to achieve the effect of reducing environmental governance costs, ensuring energy efficiency and product quality, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

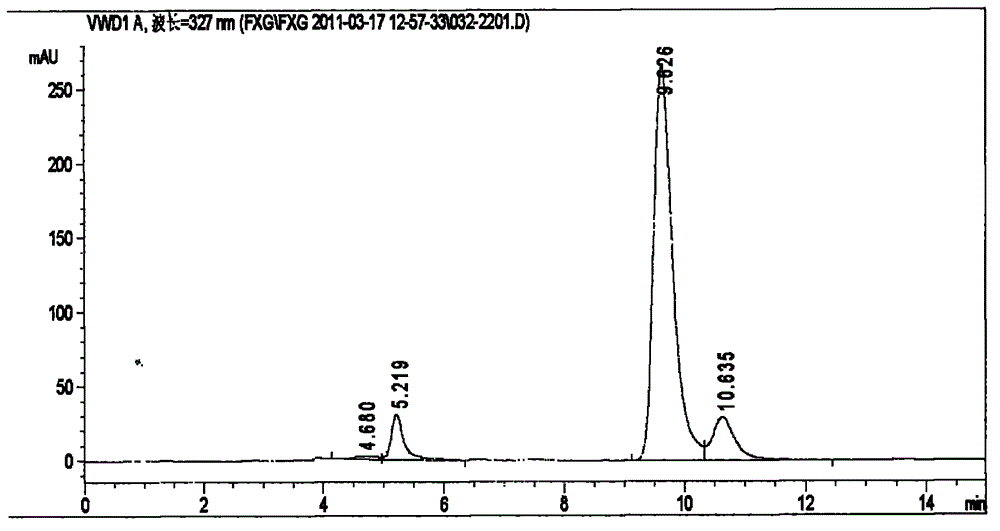

Image

Examples

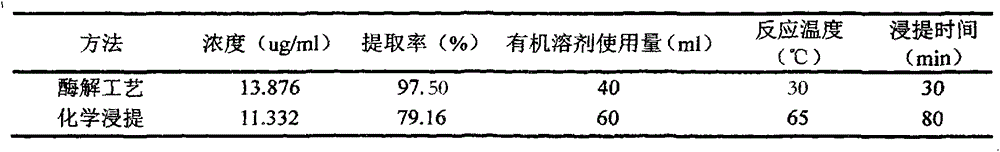

Embodiment 1

[0032] A method for extracting high-purity chlorogenic acid, the specific steps of the method are as follows:

[0033] Step 1 Honeysuckle preparation and pretreatment

[0034] Wash the honeysuckle with clean water, put it in an oven, first dry it in an oven at 50°C for 30 minutes, and then pass it through a 20-mesh sieve after being pulverized by a pulverizer. Put down the honeysuckle raw material, and then grind it in a corundum mortar for 30 minutes, pass through a 200-mesh sieve, and return the honeysuckle raw material that has not been sieved to the mortar to continue grinding. The honeysuckle material that is sieved is the pretreated honeysuckle raw material;

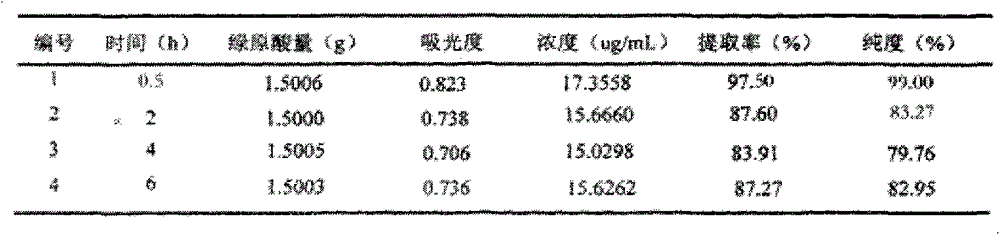

[0035] Step 2 Enzyme Treatment

[0036] After step one is finished, according to the quality of honeysuckle raw material after the pretreatment: the quality of enzyme: the ratio of the volume of water is the ratio of 1g: 0.04g: 40ml, and described enzyme is the composite of cellulase, ligninase and cex enzyme. En...

Embodiment 2

[0048] A method for extracting high-purity chlorogenic acid, the specific steps of the method are as follows:

[0049] Step 1 Eucommia leaf preparation and pretreatment

[0050] Wash the eucommia leaves with clean water, place them in an oven, and dry them in an oven at 60°C for 30 minutes, then pass them through a pulverizer and pass through a 20-mesh sieve. Collect the eucommia leaf raw material under the sieve, and then grind it in a corundum mortar for 30 minutes, pass through a 200-mesh sieve, and return the eucommia leaf raw material that has not been sieved to the mortar for further grinding. The eucommia leaf material under the sieve is the pretreated Eucommia leaf raw material;

[0051] Step 2 Enzyme Treatment

[0052] After step 1 is finished, according to the quality of eucommia leaf raw material after pretreatment: the quality of enzyme: the ratio of the volume of water is the ratio of 1g: 0.04g: 40ml, and described enzyme is cellulase, ligninase and cex enzyme ...

Embodiment 3

[0059] A method for extracting high-purity chlorogenic acid, the specific steps of the method are as follows:

[0060] Step 1 sunflower seed preparation and pretreatment

[0061] Wash the sunflower seeds with clean water, place them in an oven, and dry them in an oven at 55°C for 30 minutes, then pass them through a grinder and pass through a 20-mesh sieve, return the sunflower leaves that have not been screened to the grinder and grind them again , collect the sunflower seed raw material under the sieve, and then grind it in a corundum mortar for 30 minutes, pass through a 200-mesh sieve, and return the sunflower seed raw material that has not been sieved to the mortar for further grinding. The sunflower seed material under the sieve is the pretreatment After sunflower seed raw material;

[0062] Step 2 Enzyme Treatment

[0063]After step 1 is finished, according to the quality of sunflower seed raw material after pretreatment: the quality of enzyme: the ratio of the volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com