Low-pollution energy conservation slag system used for manufacturing hollow ingot by remelting electroslag in ingot drawing way

A technology for electroslag remelting and hollow ingot, which is applied in the field of pre-melting slag, can solve the problems of unsuitable ingot extraction electroslag remelting, easy occurrence of slag leakage or steel leakage, poor high temperature toughness, etc., and achieves good removal of inclusions. capacity, reduction of slag leakage and steel leakage, the effect of high temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

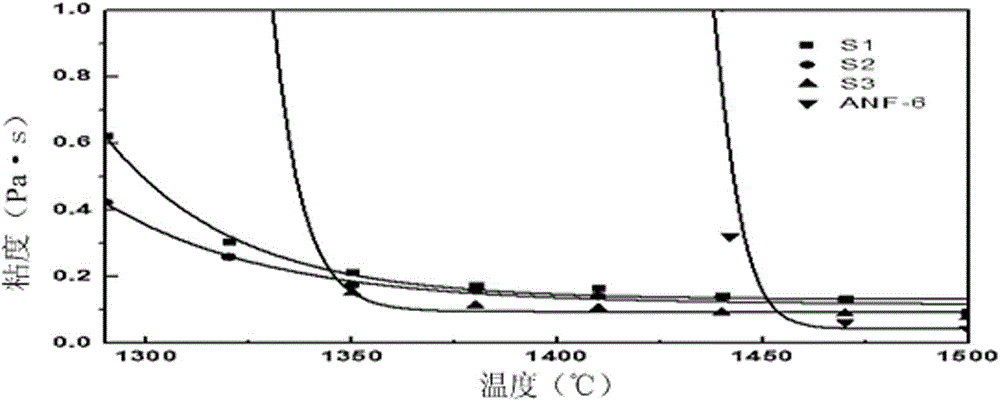

Embodiment 1

[0027] Fluorite, lime, industrial alumina, fused magnesia, silica and sodium carbonate are used as raw materials. The prepared raw materials are mixed and melted in a three-phase electric arc furnace. The materials are all melted and stirred evenly. Refined for 30 minutes; then poured into a cast iron plate with a bottom thickness of 100mm, cooled and solidified to room temperature for 4 hours, crushed with a crusher and sieved out the part with a particle size of 1~10mm, and obtained the electroslag for ingot pumping The low-pollution and energy-saving pre-melted slag of the hollow ingot is remelted, packed into a 20kg bag, and used in a power slag furnace; the composition of the above-mentioned pre-melted slag is Al by weight percentage 2 o 3 15%, CaO37%, SiO 2 14%, MgO1%, Na 2 O3%, the balance is CaF 2 And unavoidable impurities; binary alkalinity CaO / SiO 2 is 2.64, the melting temperature is 1250~1270°C, and the resistivity at 1600°C is 0.512Ω·cm; its temperature-visco...

Embodiment 2

[0032] Fluorite, lime, industrial alumina, fused magnesia and silica are used as raw materials. The prepared raw materials are mixed and melted in a three-phase electric arc furnace. After all the materials are melted, they are stirred evenly and refined at 1550~1580°C for 30 minutes. then poured into a cast iron plate with a thickness of 100mm at the bottom, cooled and solidified to room temperature for 4.5 hours, crushed by a crusher and sieved out the part with a particle size of 1-10mm, and obtained the ingot-type electroslag remelting Get the low-pollution and energy-saving pre-melted slag of the hollow ingot, pack it into a bag of 20kg, and use it in a power slag furnace; the composition of the above-mentioned pre-melted slag is Al by weight percentage 2 o 3 20%, CaO35%, SiO 2 10%, MgO3%, the balance is CaF 2 And unavoidable impurities; binary alkalinity CaO / SiO 2 is 3.5, the melting temperature is 1270~1280°C, and the resistivity at 1600°C is 0.569Ω·cm; its temperatu...

Embodiment 3

[0036] Fluorite, lime, industrial alumina, fused magnesia and silica are used as raw materials to prepare low-pollution and energy-saving pre-melted slag for hollow ingots produced by electroslag remelting. The method is the same as in Example 2, and its composition is as follows % by weight is Al 2 o 3 19%, CaO36%, SiO 2 12%, MgO3%, the balance is CaF 2 And unavoidable impurities; binary alkalinity CaO / SiO 2 is 3, the melting temperature is 1260~1280°C, and the resistivity at 1600°C is 0.603Ω·cm;

[0037] Adopt above-mentioned premelting slag electroslag remelting high-pressure boiler steel P91, method is the same as embodiment 1, difference is:

[0038] During electroslag remelting, the amount of pre-melted slag is 300~350kg / furnace steel, the voltage is 72~76V, the current is 20~22kA, and the melting rate is 1000~1100kg / h. The casting speed is 5~6 mm / min; the size of the produced hollow ingot is Φ900 / Φ500mm, the inner and outer surfaces of the hollow ingot are of good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com