Method for preparing graphene/ nanocarbon particle composite

A technology of nano-carbon particles and composite materials, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of easy agglomeration of graphene, unfavorable industrialization, loss of function, etc., achieve high conductivity, low cost, and prevent agglomeration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] 1. A preparation method of graphene / carbon nanoparticle composite material, is characterized in that, comprises the steps:

[0041] 1) graphite is oxidized to prepare graphene oxide, and the resulting graphene oxide is added to water to prepare a suspension;

[0042] 2) adding the nano-carbon particles to an aqueous solution of a surfactant to obtain a suspension of the nano-carbon particles;

[0043] 3) mixing the graphene oxide suspension with the carbon nanoparticle suspension to obtain a uniformly mixed suspension of the graphene oxide / carbon nanoparticle;

[0044] 4) spray drying the homogeneously mixed suspension obtained in step 3) to obtain a powder;

[0045] 5) the powder obtained in step 4) is processed as follows:

[0046] a) performing a reduction treatment under a reducing atmosphere, after the reduction is completed, cooling to room temperature under a reducing atmosphere, cleaning and drying, and finally obtaining a graphene composite material loaded w...

Embodiment 1

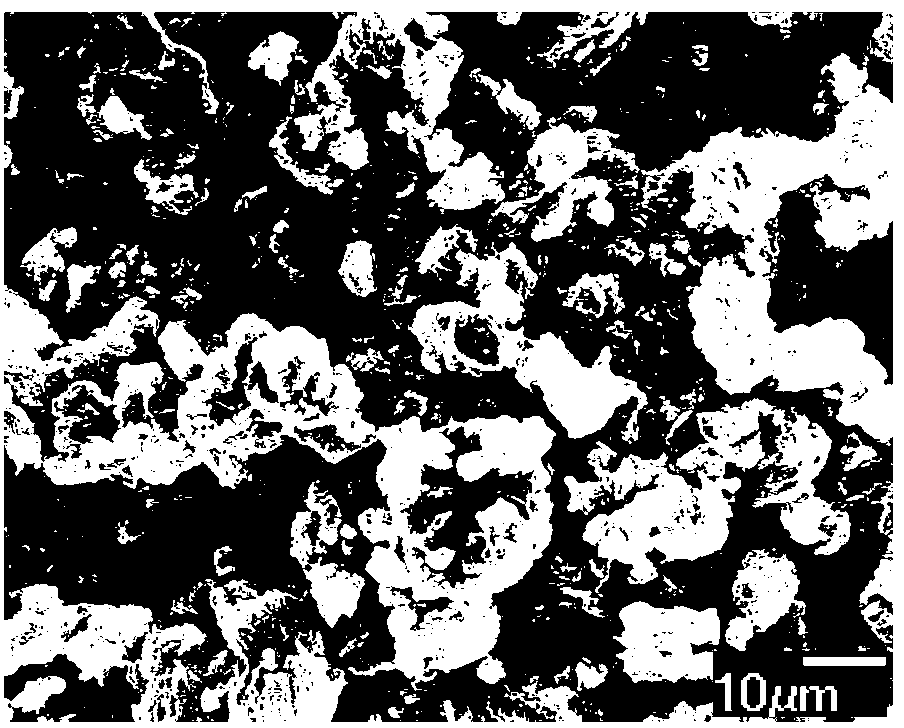

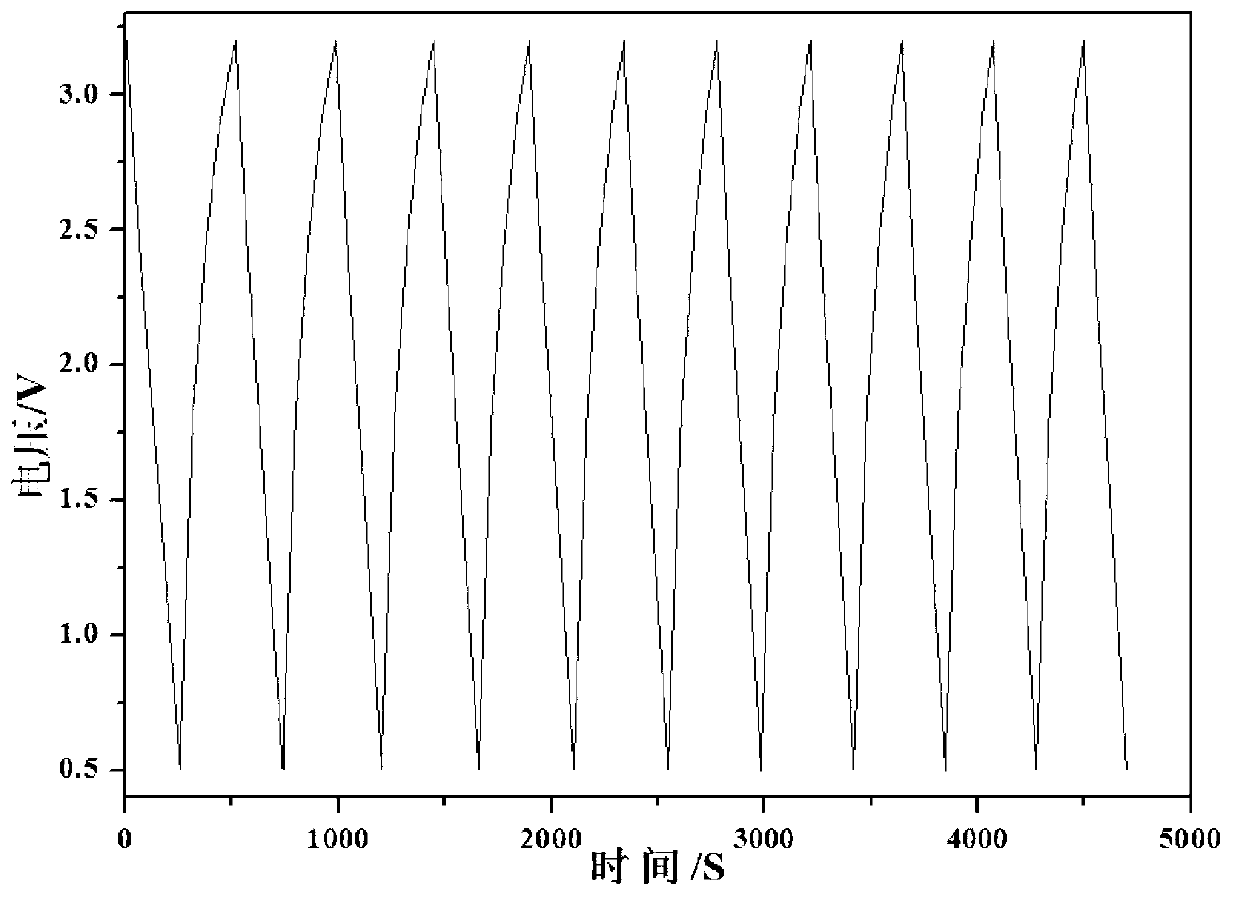

[0062] (1) Preparation of graphene oxide suspension: Obtain graphene oxide (see JACS, 1958,80,1339) by oxidation-reduction method (hummers improved method): its specific steps are 20g of 50 mesh graphite powder, 10g persulfuric acid Potassium and 10g of phosphorus pentoxide were added to concentrated sulfuric acid at 80°C, stirred evenly, cooled for 6 hours, washed until neutral, and dried. Add the dried sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the mixture below 20°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water . After 15 minutes, add 2.8L of deionized water (which contains 50mL of 30% hydrogen peroxide), and then the color of the mixture turns bright yellow. Suction filtration while hot, and then wash with 5L of 10% hydrochloric acid, and suction filtration , vacuum drying at 60° C. for 48 hours to obtain graphene oxide, which was added to deionized water and...

Embodiment 2

[0069] (1) Preparation of graphene oxide suspension: prepare graphene oxide suspension in the same manner as in Example 1.

[0070](2) Preparation of nanocarbon particle suspension: add 10g Ketjen Black ECP600JD (Switzerland, Temigo ECP600JD, particle size 20nm) and 5g surfactant dodecyl tetraethyl quaternary ammonium salt to 500mL deionized water , Ultrasonic power is 100w to disperse for 30min, so as to obtain a homogeneous suspension of Ketjen Black ECP600JD.

[0071] (3) Preparation of the mixed suspension: mix the suspension of the graphene oxide with the suspension of Ketjen Black ECP600JD, and stir at room temperature for 10 hours to obtain a uniformly dispersed mixed suspension; wherein the Ketjen Black ECP600JD is mixed with the oxidized The mass ratio of graphene is 1:20;

[0072] (4) Prepare the mixture of Ketjen Black ECP600JD particles and graphene by spray drying: under the spray pressure of 6MPa, the inlet air temperature of 200°C, and the outlet air temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com