Rare earth/tourmaline composite material, as well as preparation method and application thereof

A technology of composite materials and tourmaline, which is applied in the field of rare earth/tourmaline composite materials and their preparation, can solve problems such as difficult to completely remove and difficult to quickly degrade, and achieve fast adsorption speed, easy recycling, and improved material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A rare earth / tourmaline composite material is prepared through the following steps:

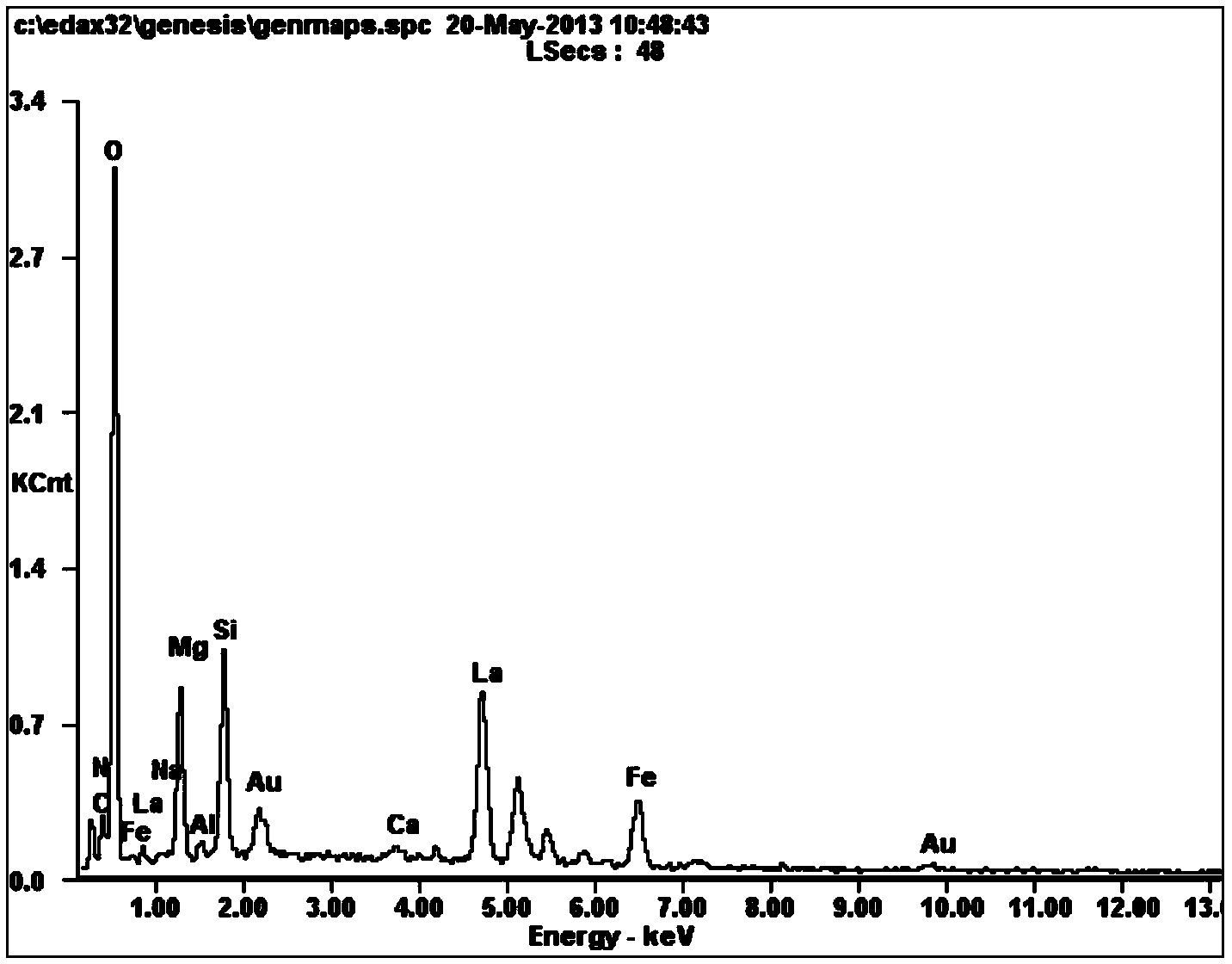

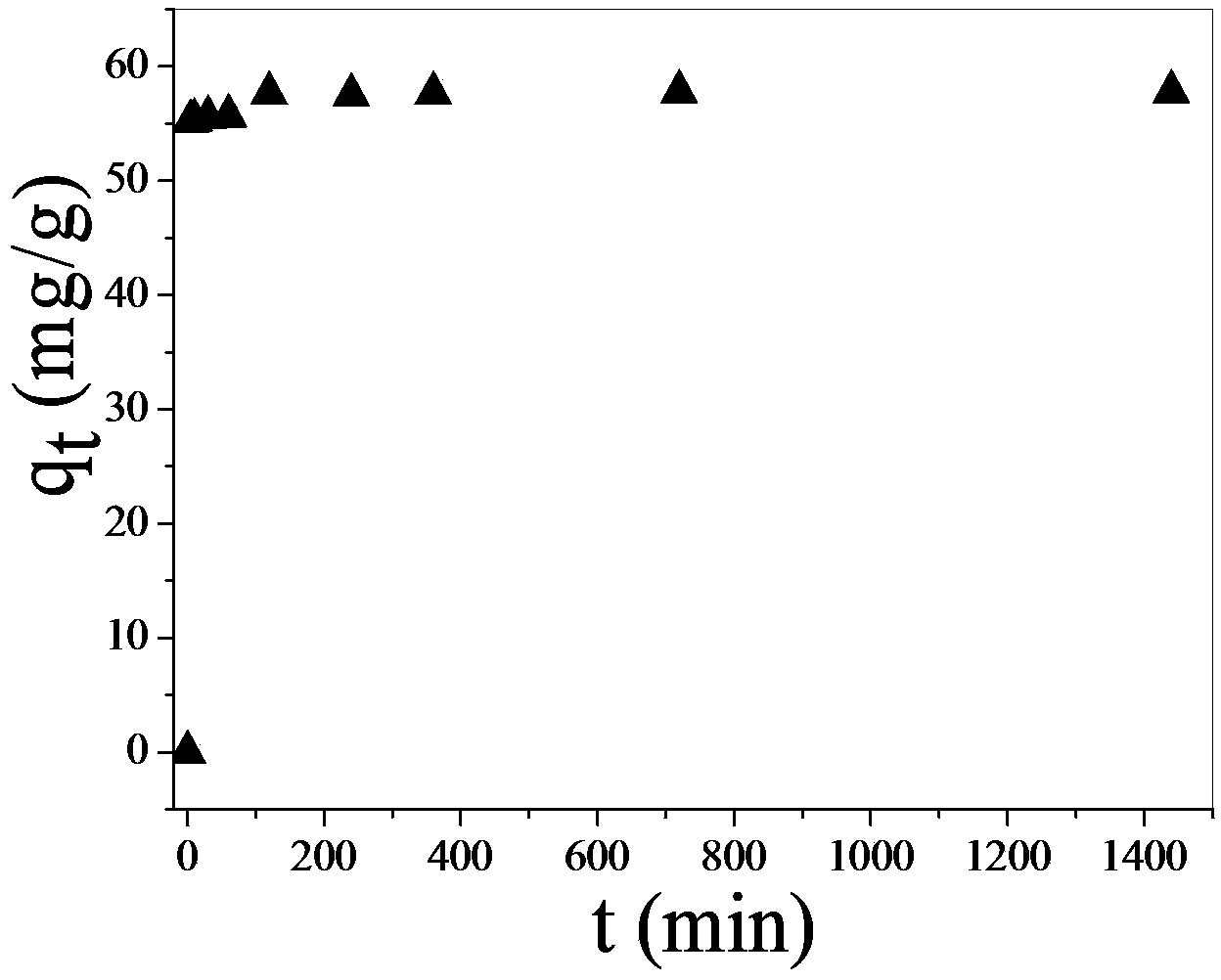

[0029] The natural mineral tourmaline was ground and passed through a 300-mesh sieve, and 10 g was added to 50 mL 0.5 M La(NO 3 ) 3 In the solution, ultrasonic (20 KHz ~ 40 KHz) was dispersed for 5 minutes, then electromagnetically stirred for 24 hours. After solid-liquid separation, the obtained solid material was dried at 65°C for 12 hours to prepare rare earth lanthanum-modified tourmaline. The scanning electron micrograph and energy spectrum analysis figure of this rare earth lanthanum modified tourmaline can be found in figure 1 , figure 2 , the analysis of its electron microscope photos shows that the natural tourmaline material used still maintains the morphology characteristics of natural tourmaline after modification, and the particle size is in the micron order; through energy spectrum analysis, it can be seen that the rare earth lanthanum modified tourmaline ...

Embodiment 2

[0035] Example 2 A rare earth / tourmaline composite material, the preparation method of which is basically the same as that of Example 1, except that the modified tourmaline obtained by solid-liquid separation is calcined at 300°C for 2 hours.

[0036]Take 10 mg of the above-mentioned rare earth lanthanum-modified tourmaline and add it to 50 mL of tetracycline solution with pH=5.0. After adsorption for 24 h, the pH can be automatically adjusted to 7.4.

Embodiment 3

[0037] Embodiment 3 Bactericidal test

[0038] Take 300 mg of the rare earth lanthanum-modified tourmaline described in Example 1, add it to 30 mL of Staphylococcus aureus solution, cultivate it in a constant temperature incubator at 36 °C for 6 h, and calculate the number of colonies, and the average antibacterial rate reaches 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com