Metal nanowire detector and method for measuring vacuum ultraviolet intensity

A technology of vacuum ultraviolet light and metal nanowires, which is applied in photometry and spectrum investigation using electric radiation detectors, can solve the problems of low signal-to-noise ratio and reduce the measurement signal strength, achieve signal stability and increase current signal Intensity, large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

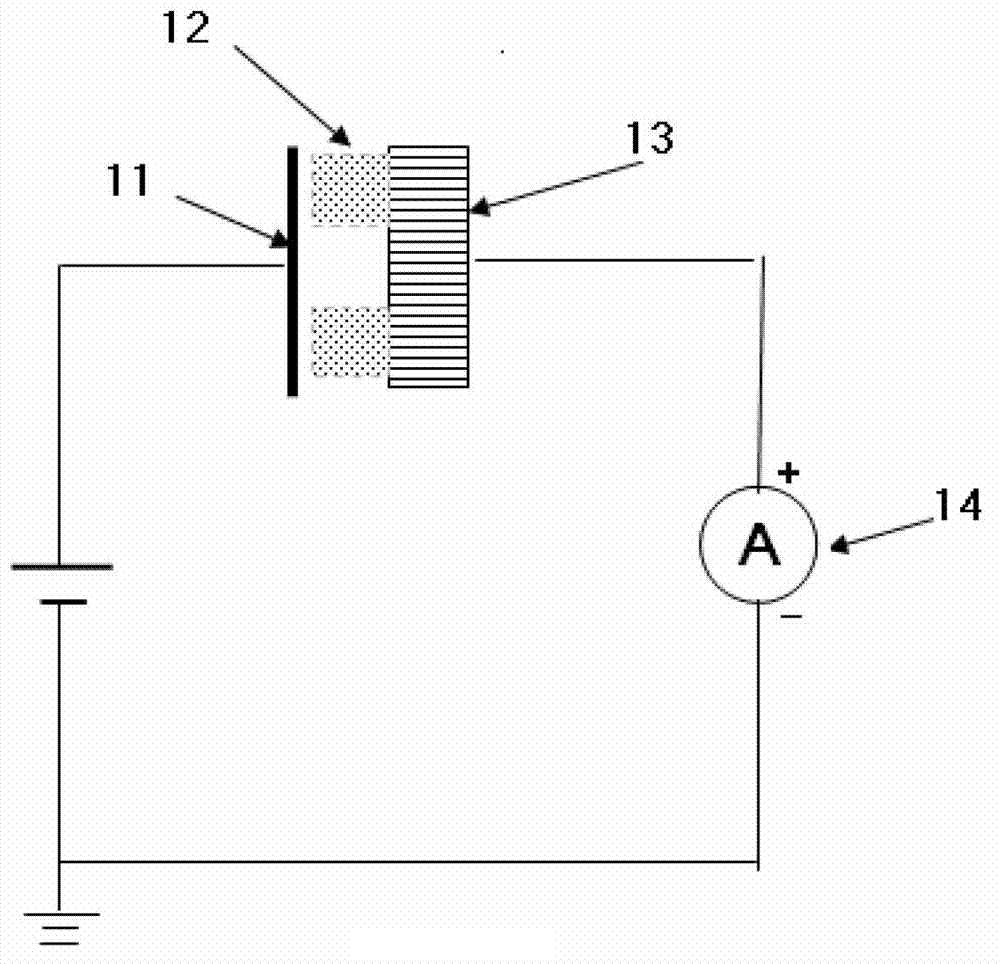

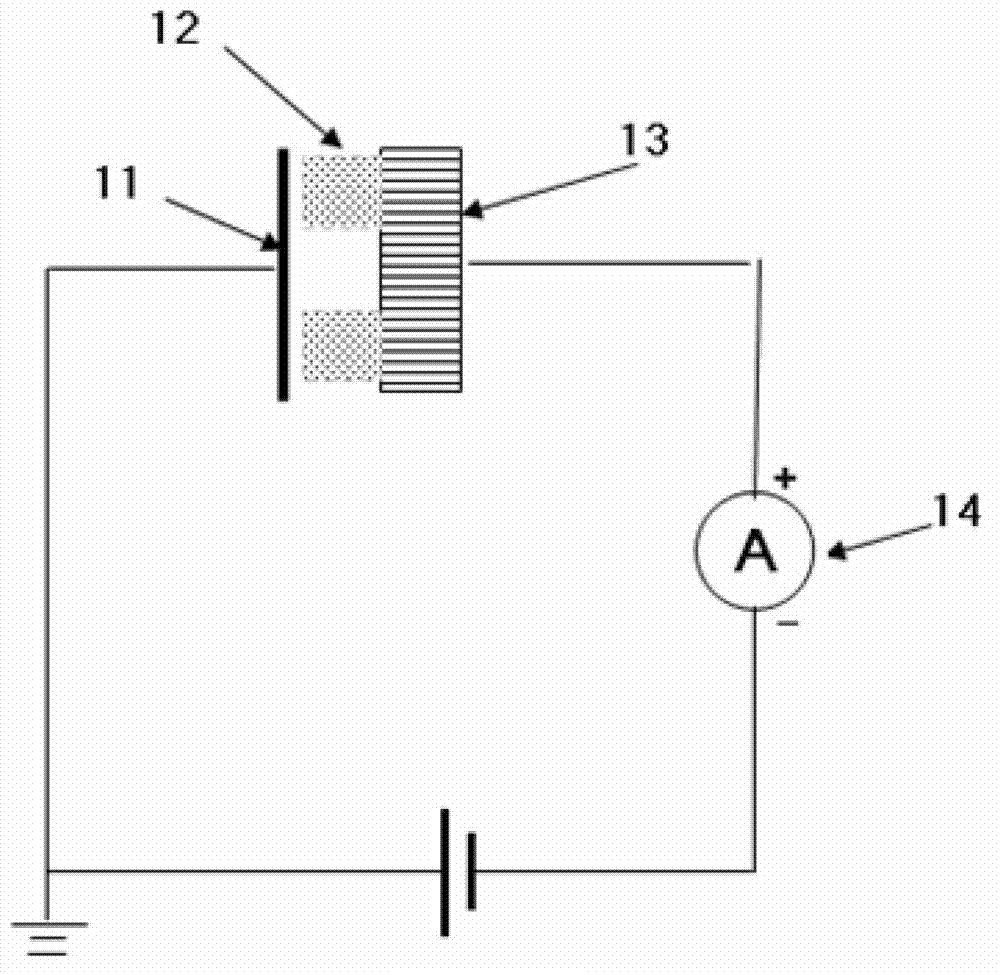

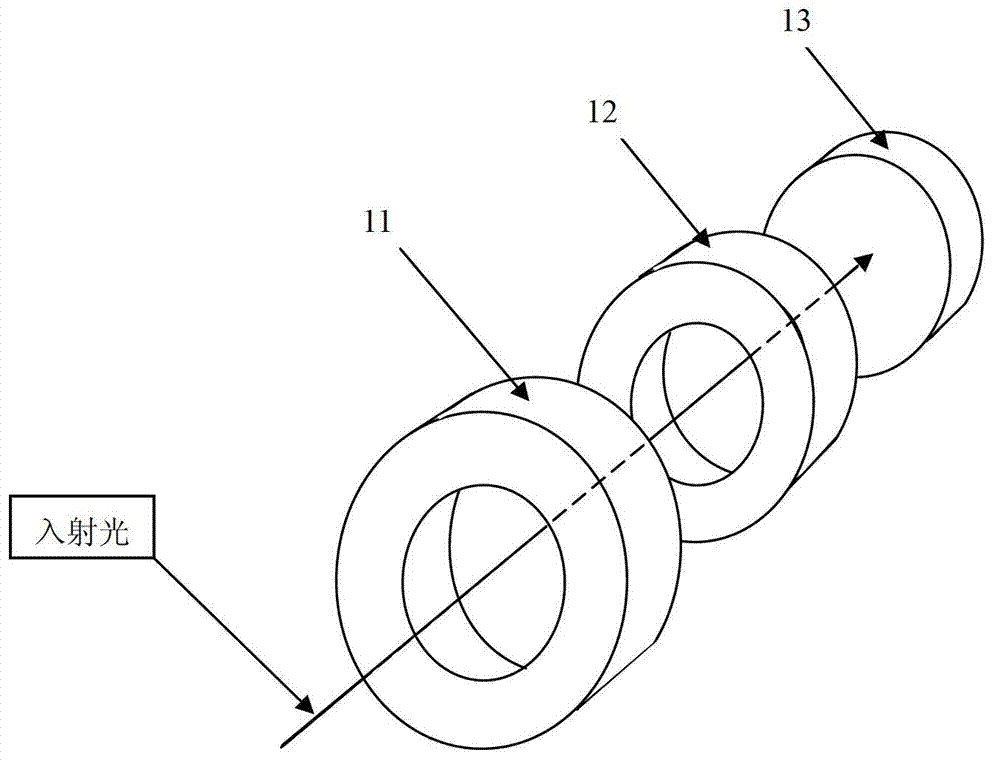

Embodiment 1

[0065] In this example, installed in I 0 The transmission standard detector at the position of the detector 3 is a Si photodiode detector calibrated by the US NIST (National Institute of Standards and Technology), the model is AXUV-100G, and the quantum efficiency is η S Indicates (calibration results see Figure 7 ). Ammeter 14 is preferably a 6517A Electrometer / Megger (Keithley, Instruments Inc., USA). Detector 5 is a calibrated Ni metal nanowire detector, wherein the porous anodized aluminum template of the metal nanowire detector is in the shape of a disc, the diameter of each nanohole is 40nm, the hole spacing is about 100nm, and the hole depth is 50μm ; By an electrochemical deposition method, the elemental metal Ni is deposited into the nanopore, and the elemental metal Ni nanowire is grown in the nanopore. The polarizer 4 is a molybdenum-silicon (Mo-Si) multilayer film polarizer.

[0066] Measurement steps:

[0067] 1. Under the control of the motor, move the moly...

Embodiment 2

[0077] In the method of the present embodiment, differ from embodiment 1 in that:

[0078] 1) Detector 5 is a calibrated cobalt (Co) metal nanowire detector. The diameter of the alumina template is 25mm, the diameter of each nanopore is 50nm, the spacing between the holes is about 110nm, and the hole depth is 40μm.

[0079] 2) In measurement step 2, apply a negative bias voltage of 1500V to the measurement circuit.

Embodiment 3

[0081] In the method of the present embodiment, differ from embodiment 1 in that:

[0082] 1) The detector 5 is a calibrated iron (Fe) metal nanowire detector; the diameter of the alumina template is 18mm, the diameter of each nanopore is 70nm, the distance between the holes is about 140nm, and the hole depth is 20μm.

[0083] 2) In measurement step 2, add a positive bias voltage of 2000V to the measurement circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com