Good-hydrothermal-stability hydrodeoxygenation catalyst, and preparation and application thereof

A deoxidation catalyst and stability technology, applied in the preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve good hydrothermal stability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

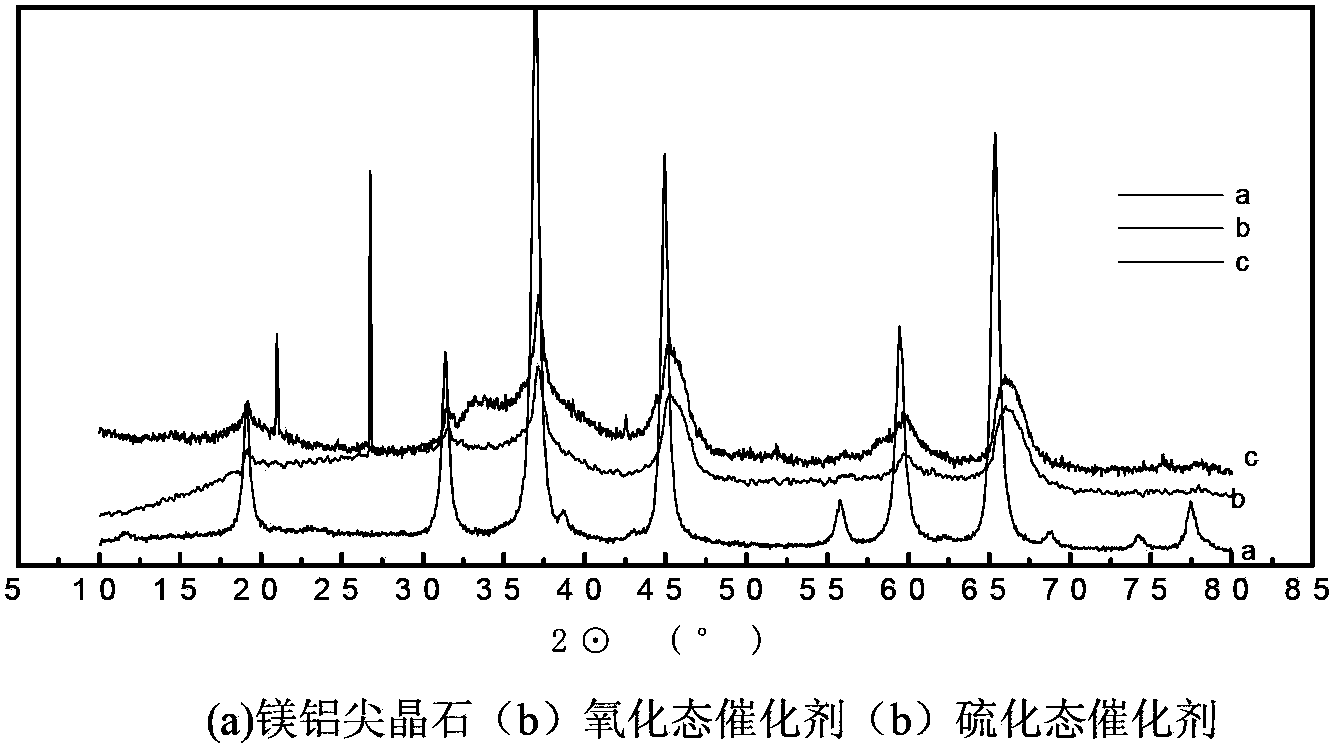

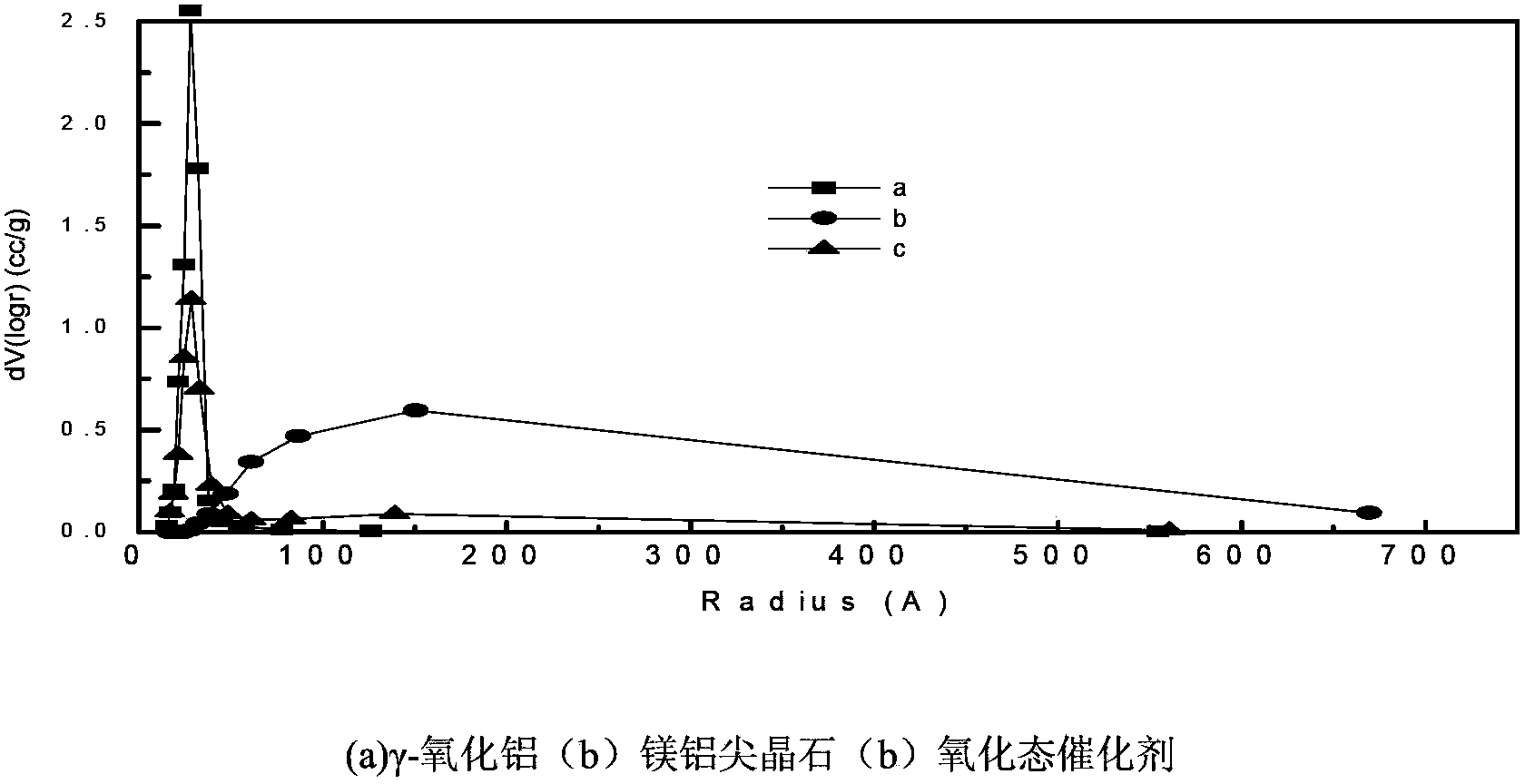

Embodiment 1

[0028] Choose a specific surface area of 230m 2 / g, 0.5ml / g pore volume, pseudo-boehmite powder with an average pore diameter of 6nm, and a surface area of 150m2 prepared in a membrane dispersion reactor at a mass ratio of 1-25:1 2 / g, pore volume 0..8ml / g, magnesium aluminum spinel with an average pore diameter of 20.4nm, mixed with turnip powder, methyl cellulose and citric acid mixed evenly. Add molybdenum trioxide at a ratio of 15-25% by mass, and after fully mixing, add 2-3mol / L nitric acid at a mass ratio of 0.8-1.2 water, knead, and put it into an extruder for forming. Dry the formed molybdenum oxide-containing carrier in an oven at 80°C for 8h-12h, then place it in a muffle furnace for 200-280min at 550-650°C, and obtain a pretreated magnesia-aluminum spinel modified catalyst carrier after cooling . Measure the water absorption of the formed carrier obtained, and prepare a nickel nitrate solution with a concentration of 0.1-1mol / L according to the pore saturated ...

Embodiment 2

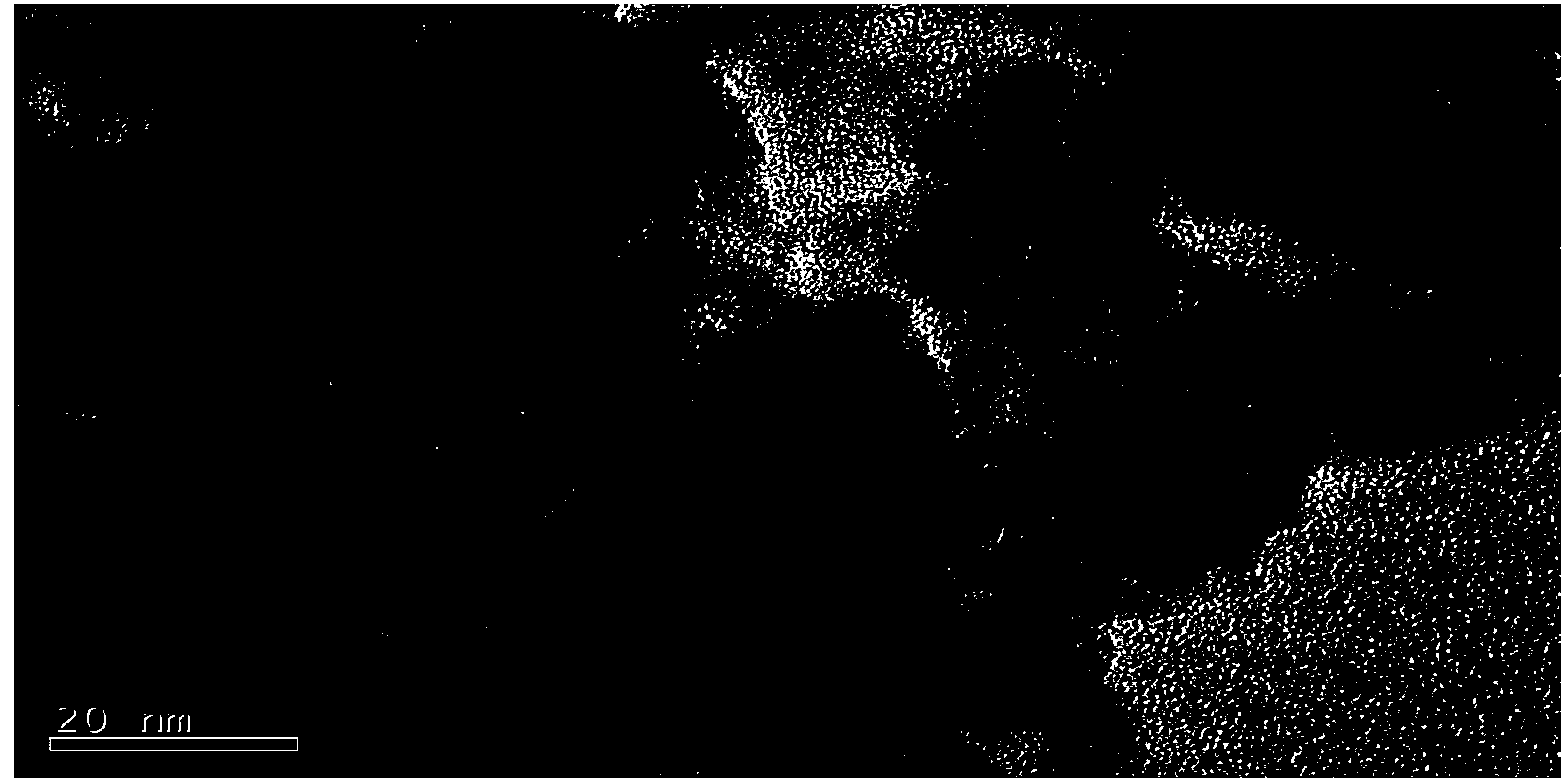

[0032] Take 15ml of catalyst in oxidation state, place it in the middle of the tube of the fixed-bed reactor, and plug it with certain mesh of quartz sand on both sides. Set the furnace temperature of the reactor to 300°C, adjust the system pressure to 2.5MPa, set the hydrogen flow rate to 100ml / min, adjust the feeding rate of the advection pump to 0.5ml / min, and stabilize the system temperature, pressure, and gas flow rate to react The device delivers 3% CS 2 After 4 hours, the liquid feed was stopped, the system pressure was removed after the hydrogen flow was stopped, the pipeline was purged with nitrogen gas and the temperature was lowered.

[0033]The TEM photograph of gained sulfide state catalyst is attached image 3 shown

Embodiment 3

[0035] Take 5ml of the sulfided catalyst in Example 2, place it in the middle of the tube of the fixed-bed reactor, and plug it with a certain number of quartz sands on both sides. Set the furnace temperature of the reactor to 300°C, adjust the system pressure to 4MPa, and adjust the feeding rate of the advection pump to 0.2ml / min. After the system temperature, pressure, and gas flow are stable, deionized water is sent to the reactor, and the liquid is stopped after 4 hours. Feeding, stop the hydrogen flow, release the system pressure, blow the nitrogen to purge the pipeline and cool down.

[0036] Take 5ml of shaped γ-alumina, place it in the middle of the tube of the fixed bed reactor, and plug it with certain mesh of quartz sand on both sides. Set the furnace temperature of the reactor to 300°C, adjust the system pressure to 4MPa, and adjust the feeding rate of the advection pump to 0.2ml / min. After the system temperature, pressure, and gas flow are stable, deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com