Method and device for storing bioelectrical energy by virtue of capacitive anode

A capacitive and bioelectric technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems that MFCs have no large-scale industrial application, difficult to directly drive MFC, difficult to electronic equipment, etc., to achieve easy industrial application and device The effect of reduced occupied area and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

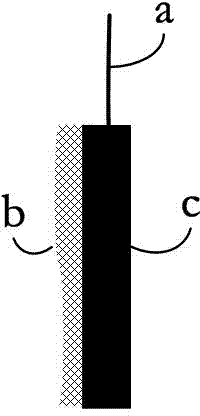

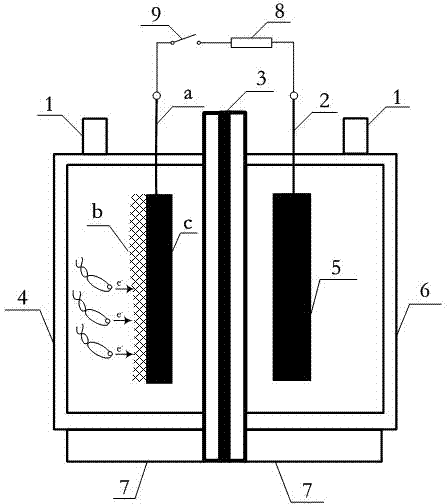

[0031] Such as figure 1 As shown, the anode is composed of an anode wire (titanium wire) a, a supercapacitor material modification layer b, and a substrate electrode c.

[0032] Prepare supercapacitive electrodes as follows:

[0033] (1) Put the graphite felt in a hydrogen peroxide solution with a mass fraction of 10%, boil it in a water bath at 90 °C for 2 hours, then boil it with deionized water at the same temperature for 2 hours, and then dry it in an oven;

[0034] (2) Cut the graphite felt into (length 2 cm × width 3 cm) size;

[0035] (3) Wear the graphite felt with titanium wire.

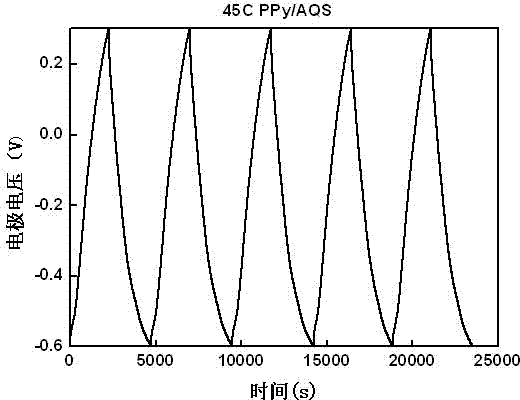

[0036] (4) Modification of graphite felt: 5 mmol / L anthraquinone-2,6-disulfonic acid sodium salt (AQS) was used to modify graphite felt, and the volume ratio of pyrrole was controlled at 100 (AQS):1. Electrochemical workstation CHI 660C applied 45 C electricity to the graphite felt at a constant voltage of 0.8 V to obtain polypyrrole (PPy) / (AQS) modified electrodes.

[0037] In th...

Embodiment 2

[0045] The difference between this embodiment and Example 1 is that the anode modification method uses polypyrrole (PPy) / electrochemically reduced graphene (RGO) material.

[0046] The modified anode in this embodiment is prepared as follows:

[0047] (1) Dissolve 200 mg of graphene oxide in 40 mL of deionized water to a concentration of 5 mg·mL -1 aqueous suspension of graphene oxide. Then 8 mmol of pyrrole monomer was added to the graphene oxide aqueous suspension solution to prepare a mixed solution, and the concentration of the conductive polymer monomer in the mixed solution was 0.2 mol L -1 , after magnetic stirring at room temperature for 10 min, and ultrasonication for 5 min, the mixed electrolyte was prepared;

[0048] (2) Put the graphite felt in a hydrogen peroxide solution with a mass fraction of 10%, boil it in a water bath at 90 °C for 2 hours, then boil it with deionized water at the same temperature for 2 hours, and then dry it in an oven to dry the graphi...

Embodiment 3

[0053] The difference between this embodiment and Example 1 is that the anode modification method uses RuO 2 Material.

[0054] The modified anode in this embodiment is prepared as follows:

[0055] (1) Add 1 g of RuCl 3 RuCl mixed with 50 mL of aqueous solution 3 aqueous solution;

[0056] (2) Put the graphite felt in a hydrogen peroxide solution with a mass fraction of 10%, boil it in a water bath at 90 °C for 2 hours, then boil it with deionized water at the same temperature for 2 hours, and then dry it in an oven to dry the graphite felt Cut it into a size (length 2 cm × width 3 cm), and thread the graphite felt with titanium wire to obtain a pretreated graphite felt anode.

[0057] (3) Using an electrochemical workstation, a three-electrode system is used, with the pretreated graphite felt anode as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode, and the three electrodes are plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com