Method for preparing sodium percarbonate

A technology of sodium percarbonate and light sodium carbonate, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the problem of temperature control. Good, strict equipment requirements, high consumption of hydrogen peroxide, to achieve the effect of simple process, small equipment investment, high product active oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

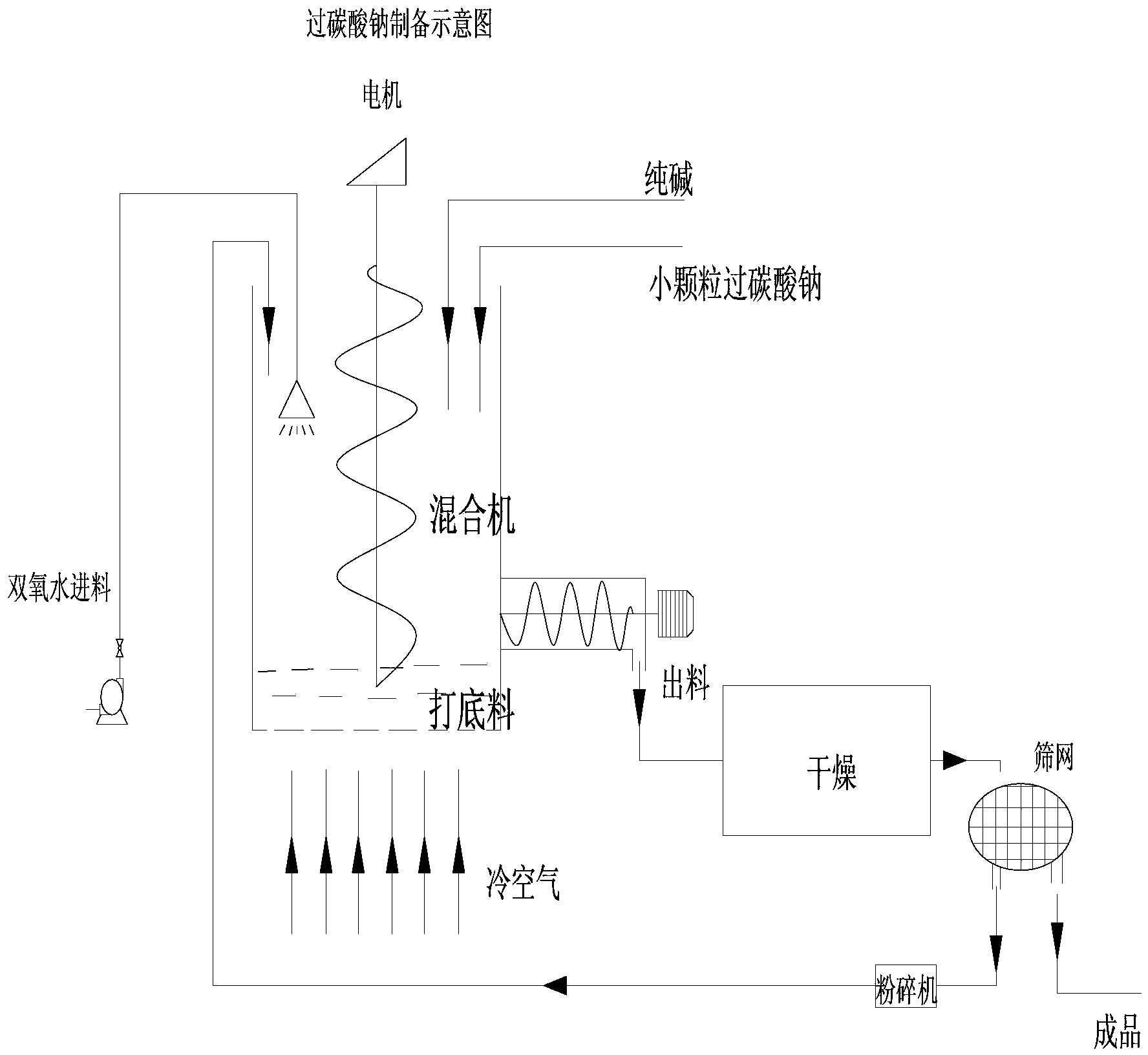

Image

Examples

Embodiment 1

[0028] 10kg particle diameter is that 0.5mm sodium percarbonate granule is added in the 50L double-cone mixer, adds 0.2kg solid stabilizer magnesium sulfate simultaneously, takes by weighing 50kg hydrogen peroxide solution (with H 2 o 250.1%), and add 0.5kg HEDP and its sodium salt solution, stir and mix well. In addition, add 0.6kg sodium metasilicate pentahydrate to 80um 56kg light soda ash and mix well. Spray the prepared hydrogen peroxide solution into the double-cone mixer, turn on the refrigerated circulating water and multi-stage blower to cool down, when the hydrogen peroxide spray reaches 0.8kg, add the light soda ash mixture while spraying the hydrogen peroxide solution. When the particle size of sodium percarbonate reaches 0.5mm-1.2mm, discharge. At the same time, according to the particle size of the material in the kettle, add 0.3mm sodium percarbonate particles to control the particle size of the product. After the output material is more than 1.2mm, it will be...

Embodiment 2

[0030] Add 15kg 0.4mm sodium percarbonate small particles into a 50L double cone mixer, add 0.15kg solid stabilizer magnesium sulfate at the same time, weigh 50kg hydrogen peroxide solution (in the form of H 2 o 2 60.1% in total), and add 0.45kg of amino trimethylene phosphonic acid and its sodium salt solution, stir and mix evenly. In addition, add 0.4kg sodium hexametaphosphate to 80um 60kg light soda ash and mix well. Spray the prepared hydrogen peroxide solution into the single cone mixer, turn on the refrigerated circulating water and the compressed air unit to cool down, when the hydrogen peroxide spray reaches 0.45kg, add light soda ash mixture while spraying the hydrogen peroxide solution. When the particle size of sodium percarbonate reaches 0.5mm-1.2mm, discharge. At the same time, according to the particle size of the material in the kettle, add 0.36mm sodium percarbonate particles to control the particle size of the product. After the output material is more than...

Embodiment 3

[0032] Add 8kg 0.5mm sodium percarbonate small particles into a 50L double cone mixer, add 0.4kg solid stabilizer magnesium sulfate at the same time, weigh 100kg hydrogen peroxide solution (in the form of H 2 o 2 55% in total), and add 1.2kg maleic acid-acrylic acid copolymer, stir and mix evenly. In addition, add 0.9kg sodium metasilicate pentahydrate and 0.5kg sodium tripolyphosphate to 80um 80kg light soda ash and mix well. Spray the prepared hydrogen peroxide solution into the double-cone mixer, turn on the refrigerated circulating water and multi-stage blower to cool down, when the hydrogen peroxide is sprayed to 0.24kg, add the light soda ash mixture while spraying the hydrogen peroxide solution. When the particle size of sodium percarbonate reaches 0.5mm-1.2mm, discharge. At the same time, according to the particle size of the material in the kettle, add 0.3mm sodium percarbonate particles to control the particle size of the product. After the output material is more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com