Method for manufacturing multi-wavelength photonic integration transmitter chip through quantum well intermixing

A quantum well hybrid, photon integration technology, applied in phonon exciters, lasers, laser components, etc., can solve problems such as lattice damage in quantum well regions, increased waveguide loss, and active integration limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

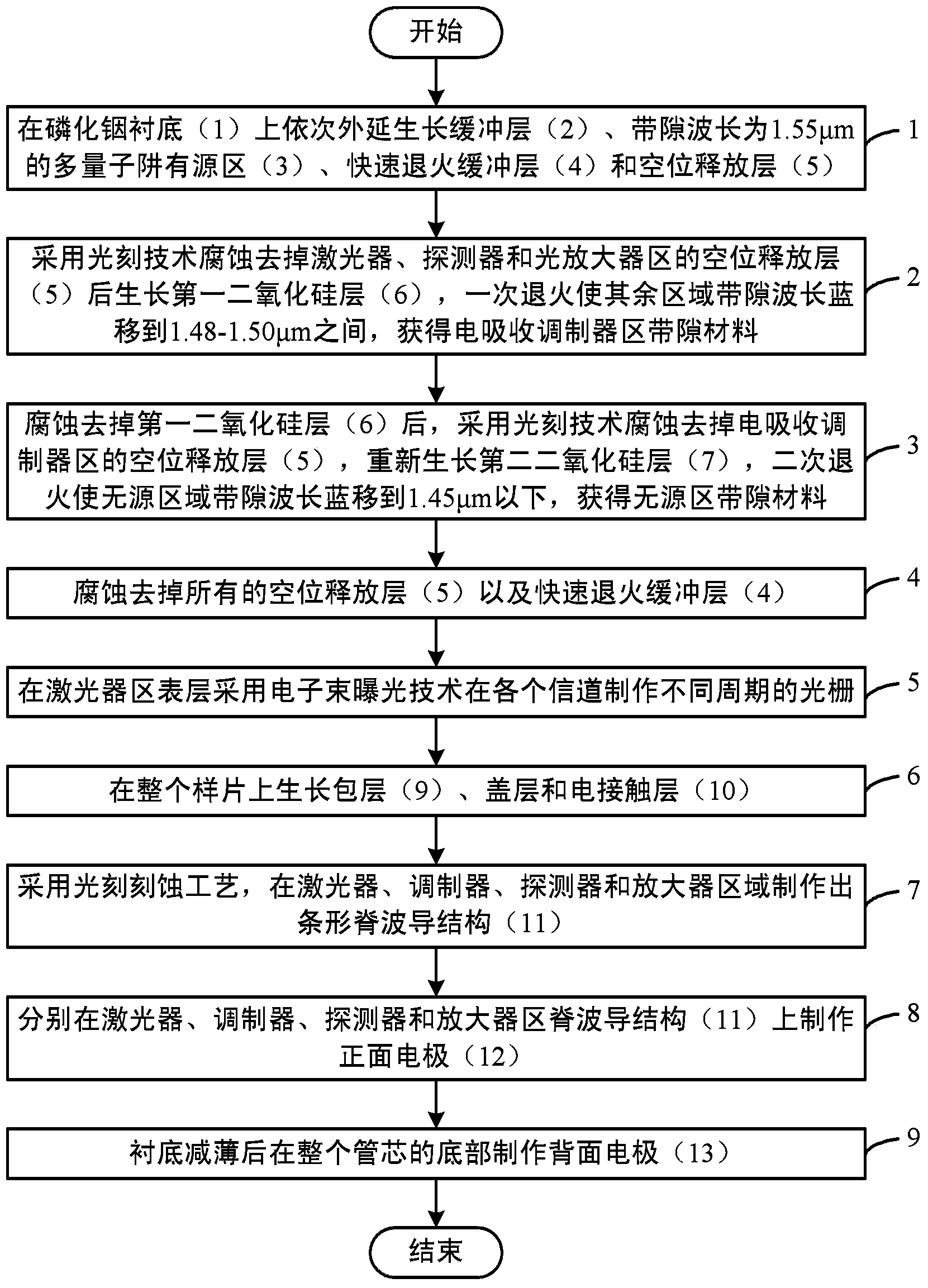

[0058] In a preferred embodiment of the present invention, described a kind of method utilizing quantum well hybridization to make multi-wavelength photon integrated emitter chip comprises the following steps:

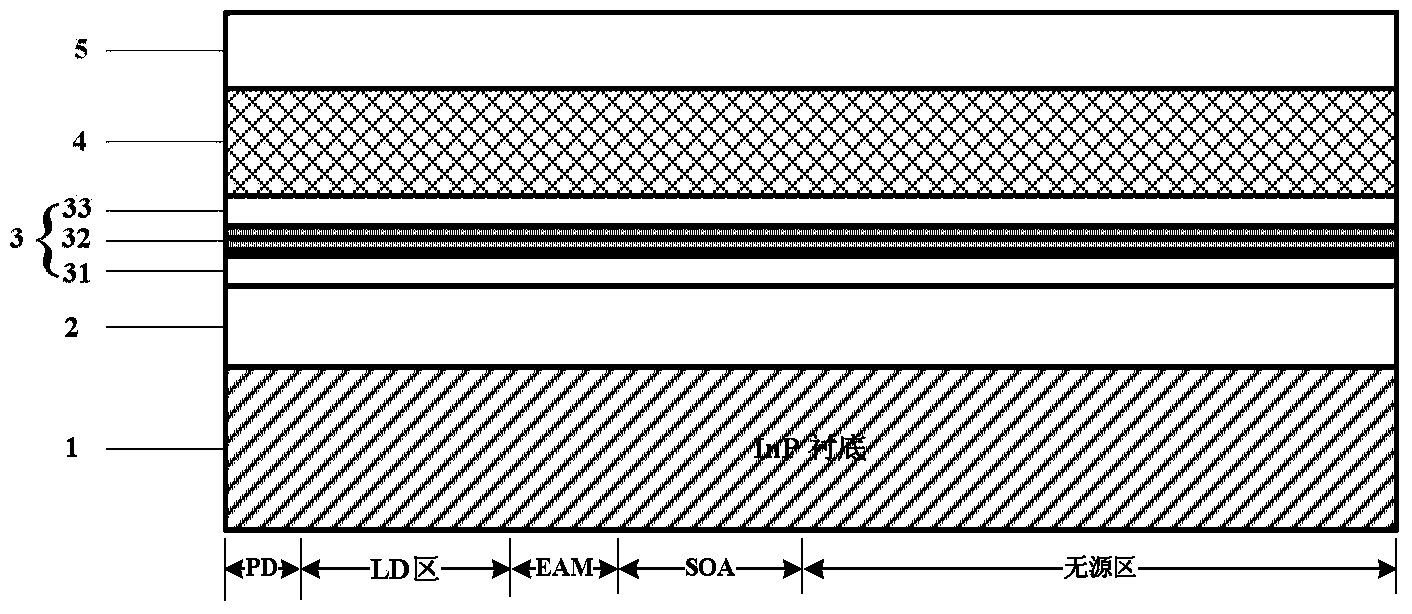

[0059] At a doping concentration of 5×10 17 cm -3 On an indium phosphide substrate 1, a buffer layer 2, a multi-quantum well active region 3 with a bandgap wavelength of 1.55 μm, a rapid annealing buffer layer 4 with a thickness of 300 nm, and a vacancy release layer 5 with a thickness of 300 nm are sequentially grown on an indium phosphide substrate. The quantum well active region 3 includes a lower waveguide layer 31 , a core layer 32 and an upper waveguide layer 33 grown sequentially.

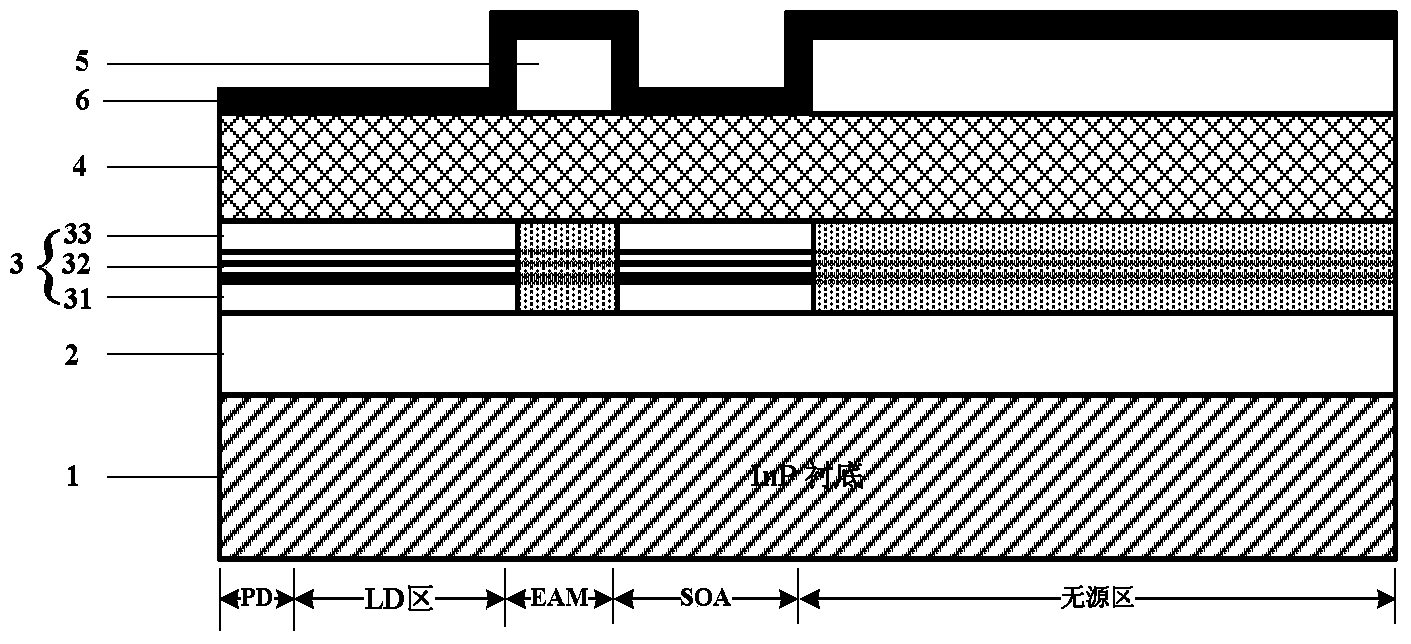

[0060] Using conventional photolithography technology, etch and remove the vacancy release layer 5 in the laser, detector and optical amplifier area, then use PECVD to grow a layer of silicon dioxide 6 with a thickness of 150nm, and anneal once at 670°C under the annealing condition...

Embodiment 2

[0065] At a doping concentration of 5×10 18 cm -3 On an indium phosphide substrate 1, a buffer layer 2, a multi-quantum well active region 3 with a bandgap wavelength of 1.55 μm, a rapid annealing buffer layer 4 with a thickness of 500 nm, and a vacancy release layer 5 with a thickness of 450 nm are grown sequentially on an indium phosphide substrate. The quantum well active region 3 includes a lower waveguide layer 31 , a core layer 32 and an upper waveguide layer 33 grown sequentially.

[0066] Using conventional photolithography technology, etch away the vacancy release layer 5 in the laser, detector and optical amplifier area, then use PECVD to grow a layer of silicon dioxide 6 with a thickness of 250nm, and anneal once at 685°C under the annealing conditions of 120s to make the band gap in the remaining areas The wavelength is blue-shifted to 1.48 μm, and the bandgap material of the electroabsorption modulator region is obtained, in which the lengths of the laser, detect...

Embodiment 3

[0071] In another preferred embodiment of the present invention, described a kind of method utilizing quantum well hybridization to make multi-wavelength photonic integrated emitter chip comprises the following steps:

[0072] At a doping concentration of 1×10 18 cm -3 On an indium phosphide substrate 1, a buffer layer 2, a multi-quantum well active region 3 with a bandgap wavelength of 1.55 μm, a rapid annealing buffer layer 4 with a thickness of 400 nm, and a vacancy release layer 5 with a thickness of 400 nm are grown sequentially on an indium phosphide substrate. The quantum well active region 3 includes a lower waveguide layer 31 , a core layer 32 and an upper waveguide layer 33 grown sequentially.

[0073] Using conventional photolithography technology, etch and remove the vacancy release layer 5 in the laser, detector and optical amplifier area, then use PECVD to grow a layer of silicon dioxide 6 with a thickness of 200nm, and anneal once at 678°C under the annealing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com