Preparation method for anionic chitosan water-treatment flocculant

An anionic, flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as harm to human health, high aluminum salt content, treatment blind spots, etc., to achieve no toxic side effects, less dosage, easy to remove. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

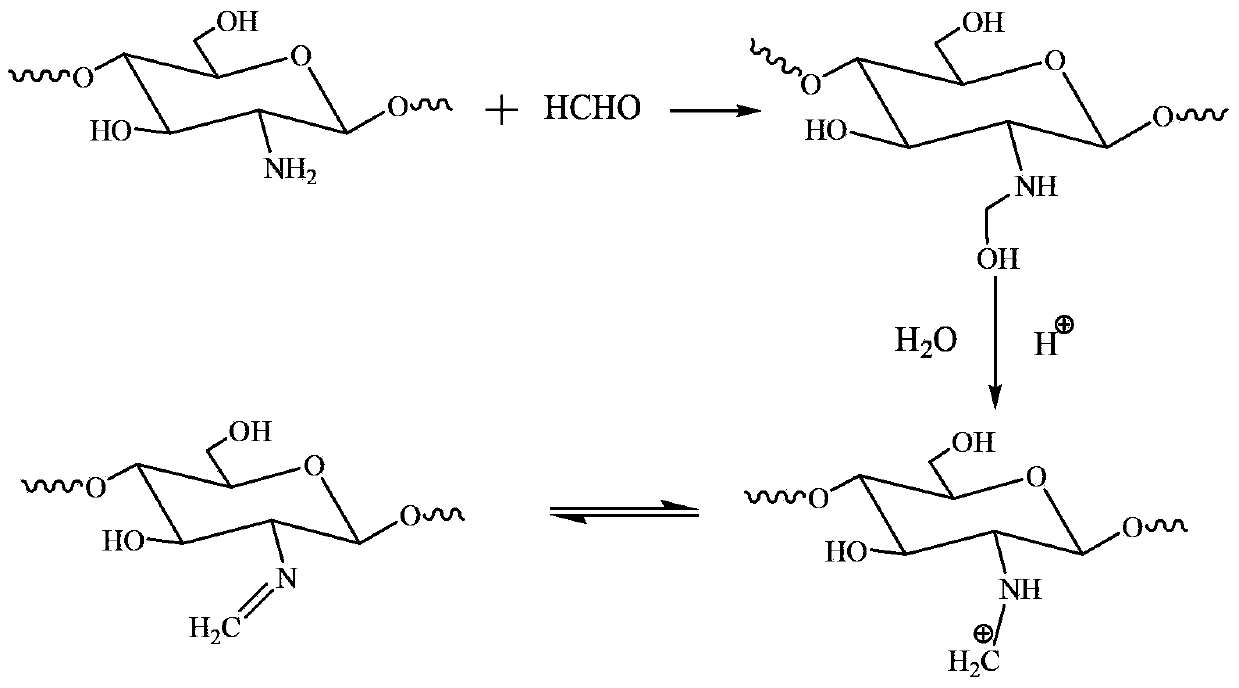

Method used

Image

Examples

Embodiment 1

[0028] 2g chitosan (deacetylation degree 83%, molecular weight 1.09×10 5 ) was dissolved in 100mL of 1% glacial acetic acid, stirred evenly at room temperature, and then 1.5mL of 50% phosphorous acid solution was continuously added dropwise at room temperature (the weight ratio of the two was 1:0.375). Raise the temperature to 90°C, stir and mix the reaction, add dropwise 50mL of 20% formaldehyde solution (5 times the mass of chitosan, 0.36mol), and reflux for 24h. The product was neutralized to pH 7.4, dialyzed and freeze-dried to obtain the product.

[0029] The anionic chitosan obtained in Example 1 is used to treat the papermaking wastewater of a certain company: directly add anionic chitosan with a concentration of 170ppm in the wastewater that has been preliminarily settled and filtered, stir quickly for a certain period of time, reduce the stirring speed, and stir slowly After a certain period of time, let it stand still and filter to obtain a clear water sample. The ...

Embodiment 2

[0031] 2g high-density chitosan (deacetylation degree 95%, molecular weight 3.40×10 8 ) was dissolved in 100mL of 1% glacial acetic acid, stirred evenly at room temperature, and then continuously added dropwise with 1.5mL of 50% phosphoric acid solution at room temperature. Raise the temperature to 90°C, stir and mix the reaction, add dropwise 50mL of 20% formaldehyde solution, and reflux for 24h. The product was neutralized to pH 7.2, dialyzed and freeze-dried to obtain the product.

[0032] The anionic chitosan obtained in Example 2 is used to treat the papermaking wastewater of a certain company: directly add anionic chitosan with a concentration of 300ppm in the wastewater through preliminary sedimentation and filtration, stir quickly for a certain period of time, reduce the stirring speed, and stir slowly After a certain period of time, let it stand still and filter to obtain a clear water sample. The COD value of the water sample was measured by the potassium dichromat...

Embodiment 3

[0034] 2g chitosan (deacetylation degree 83%, molecular weight 1.09×10 5 ) was dissolved in 100mL of 1% dilute hydrochloric acid, stirred evenly at room temperature, and then continuously added dropwise with 1.5mL of 50% phosphoric acid solution at room temperature, heated to 90°C and stirred for mixed reaction, then added dropwise with 50mL of 20% formaldehyde solution, and refluxed for 12 hours. The product was neutralized to pH 7.4, dialyzed and freeze-dried to obtain the product.

[0035] The anionic chitosan obtained in Example 3 is used to treat the papermaking wastewater of a certain company: directly add anionic chitosan with a concentration of 120 ppm in the wastewater that has been preliminarily settled and filtered, stir quickly for a certain period of time, reduce the stirring speed, and stir slowly After a certain period of time, let it stand still and filter to obtain a clear water sample. The COD value of the water sample was measured by the potassium dichromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com