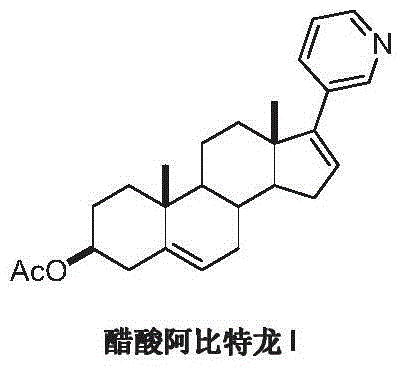

Preparation method of abiraterone acetate

A technology of abiraterone acetate and alcohol acetate, which is applied in the field of preparation of abiraterone acetate, can solve the problems of affecting the industrialization effect, difficult to purify, and reduced yield, so as to promote economic and technological development, obtain raw materials easily, Quality and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

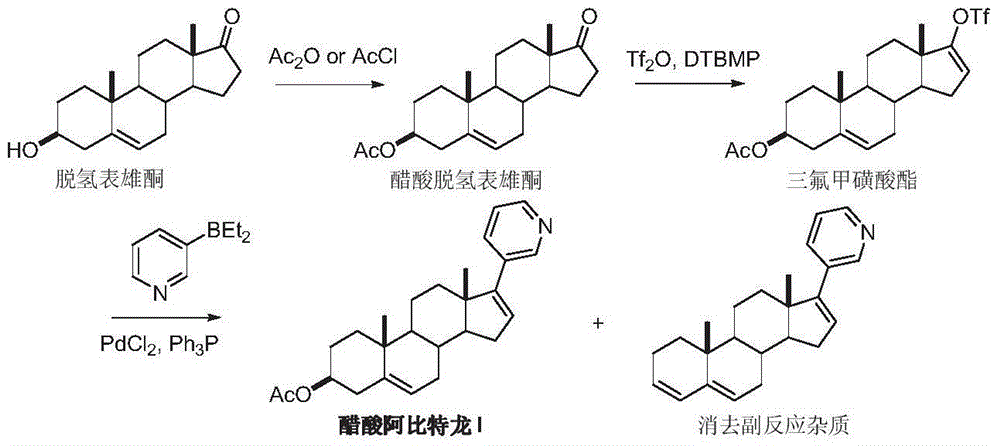

Problems solved by technology

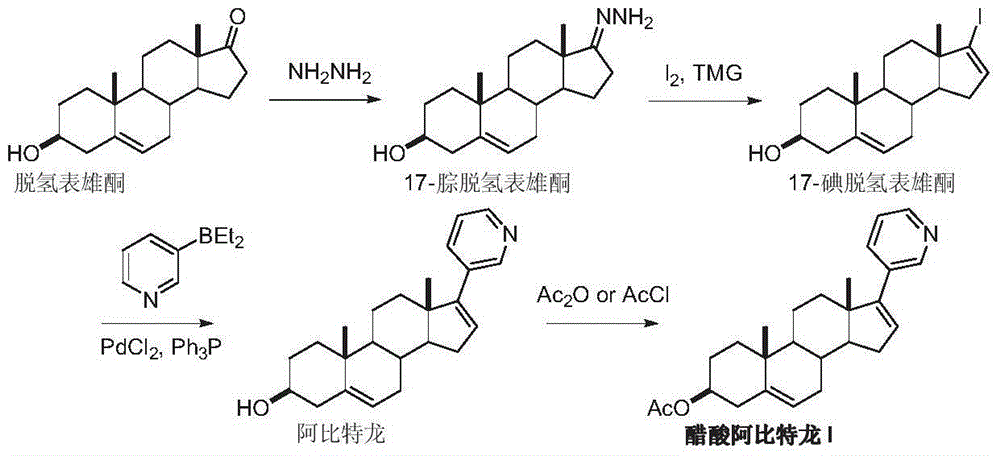

Method used

Image

Examples

Embodiment 1

[0032] Under a nitrogen atmosphere, add 3-bromopyridine (1.88g, 12mmol) and 15mL of anhydrous diethyl ether into a dry reaction flask, cool down to -78°C, add n-butyl lithium in n-hexane solution (2.5M, 5mL) dropwise, and stir React for 45 minutes. Keeping at -78°C, add DHEA (3.3 g, 10 mmol) in 25 mL of tetrahydrofuran solution dropwise to the system for about 30 minutes, then continue the reaction for 30 minutes. Naturally raised to room temperature, the reaction was stirred for 24 hours. At 0°C, the reaction was quenched with saturated ammonium chloride solution, stirred and extracted three times with dichloromethane, the organic phases were combined, washed with water and saturated brine successively, and dried over anhydrous magnesium sulfate. Dichloromethane was recovered under reduced pressure, and the residue was recrystallized from ethyl acetate / n-hexane to obtain 1.74 g of 17-(3-pyridine)-17-hydroxy-androst-5-en-3β-ol acetate (II). The rate is 87.2%.

Embodiment 2

[0034] Under a nitrogen atmosphere, add 17-(3-pyridine)-17-hydroxyl-androst-5-en-3β-ol acetate (II) (2.05g, 5mmol) and toluene 25mL in a dry reaction flask, stir Add methyl N-(triethylammoniumsulfonyl)carbamate (Burgess reagent) (1.28 g, 5 mmol), react at room temperature for 1 hour, raise the temperature to 85° C., and continue the reaction for 1 hour. Add Burgess reagent (1.28 g, 5 mmol), react at room temperature for 1 hour, and continue to react for 1 hour after raising the temperature to 85°C. TLC detects that the reaction is complete. Cool and quench the reaction with ice water. The organic phase was separated, and the aqueous phase was extracted twice with toluene. The organic phases were combined, washed with water and brine in turn, and dried over anhydrous sodium sulfate. Toluene was recovered under reduced pressure, and the residue was recrystallized from methanol / water to obtain 3.0 g of abiraterone acetate (I), with a yield of 90.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com