Modified polyarylether ketone and preparation method thereof

A polyaryletherketone, modification technology, applied in the field of modified polyaryletherketone and its preparation, can solve the problems of material modulus decrease, processing difficulty, polyaryletherketone high melting point, etc., to reduce ether exchange effect, improve Aggregate structure, effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of the modified polyaryletherketone represented by the above formula (I), comprising:

[0047] A) Under the protection of an inert gas, mix imidazole monomers, bisphenol monomers, disubstituted benzophenones of the formula (IV) and the first aprotic solvent, and react with heating under the action of carbonate to obtain Modified polyaryletherketone represented by formula (I);

[0048] The imidazole monomer has a structure of formula (II-1) or formula (II-2);

[0049] The bisphenol monomer has a structure of formula (III-1), formula (III-2) or formula (III-3);

[0050]

[0051] The-Ar 1 -One of the structures selected from the following formulas (1) to (2):

[0052]

[0053] The-Ar 2 -One of the structures selected from the following formulas (4) to (6):

[0054]

[0055]

[0056] Among them, A 1 with A 2 Each independently is S or O; R 1 with R 2 each independently selected from H, NH 2 , NO ...

Embodiment 1

[0071] 0.671g (0.005mol) benzimidazolone (HBI), 1.141g (0.005mol) bisphenol A (BPA), 2.182g difluorobenzophenone (DFK), 2.763g Potassium carbonate, 1.500g calcium carbonate, 15ml N-methylpyrrolidone (NMP) and 20ml toluene, heated to 132°C and kept for 2.5h, azeotropically removed water, raised temperature to remove toluene, continued heating to 195°C, reacted for 6h, cooled down, added Dilute with 20ml of N,N-dimethylacetamide, precipitate in a mixed solution of ethanol, water and acetic acid, filter the precipitate, extract with deionized water for 12h in a Soxhlet extractor, remove inorganic salts and reaction solvents, and dry , to obtain the modified polyaryletherketone shown in formula (I-a), the yield is 94%, and its reaction formula is as follows:

[0072]

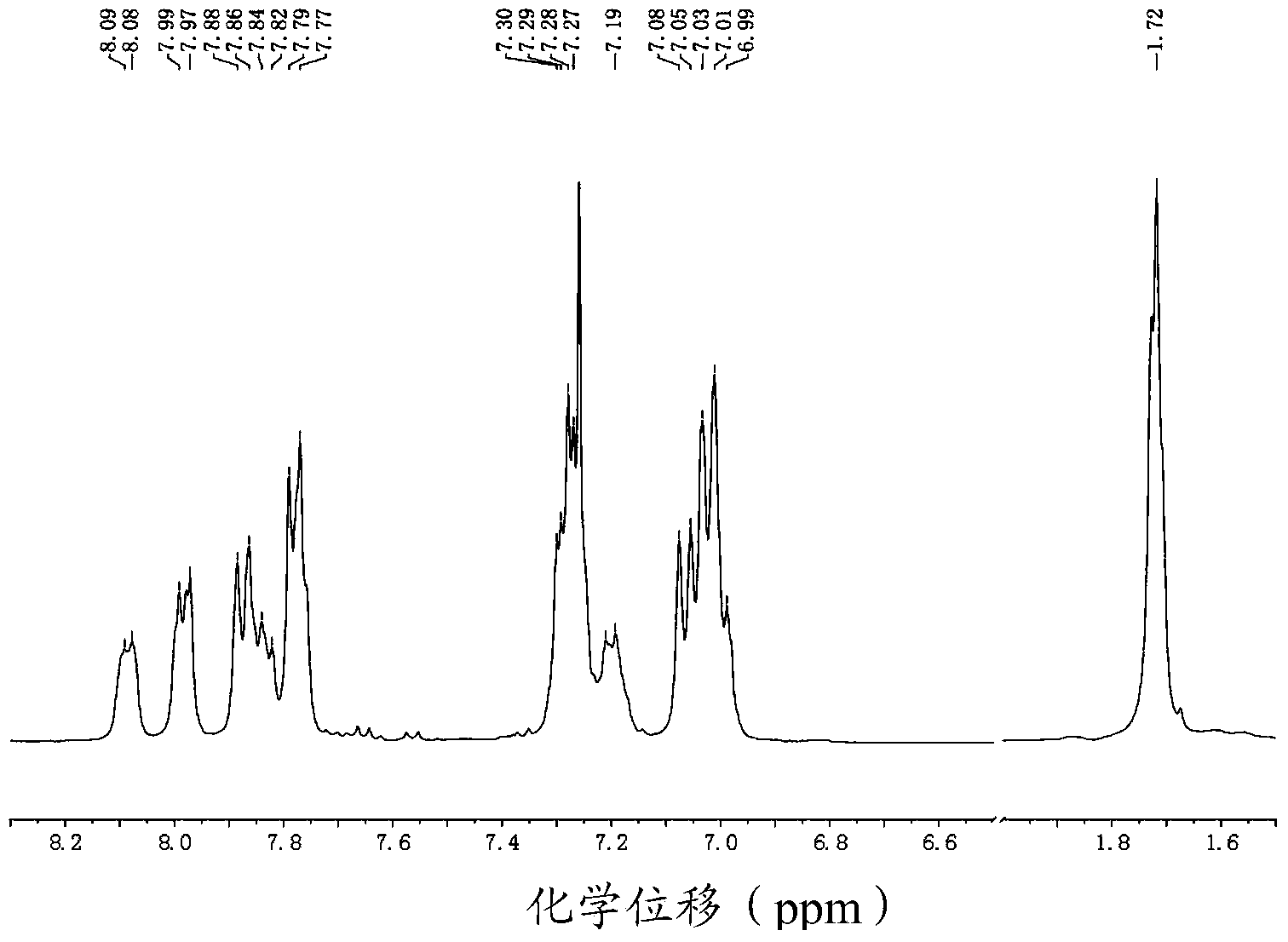

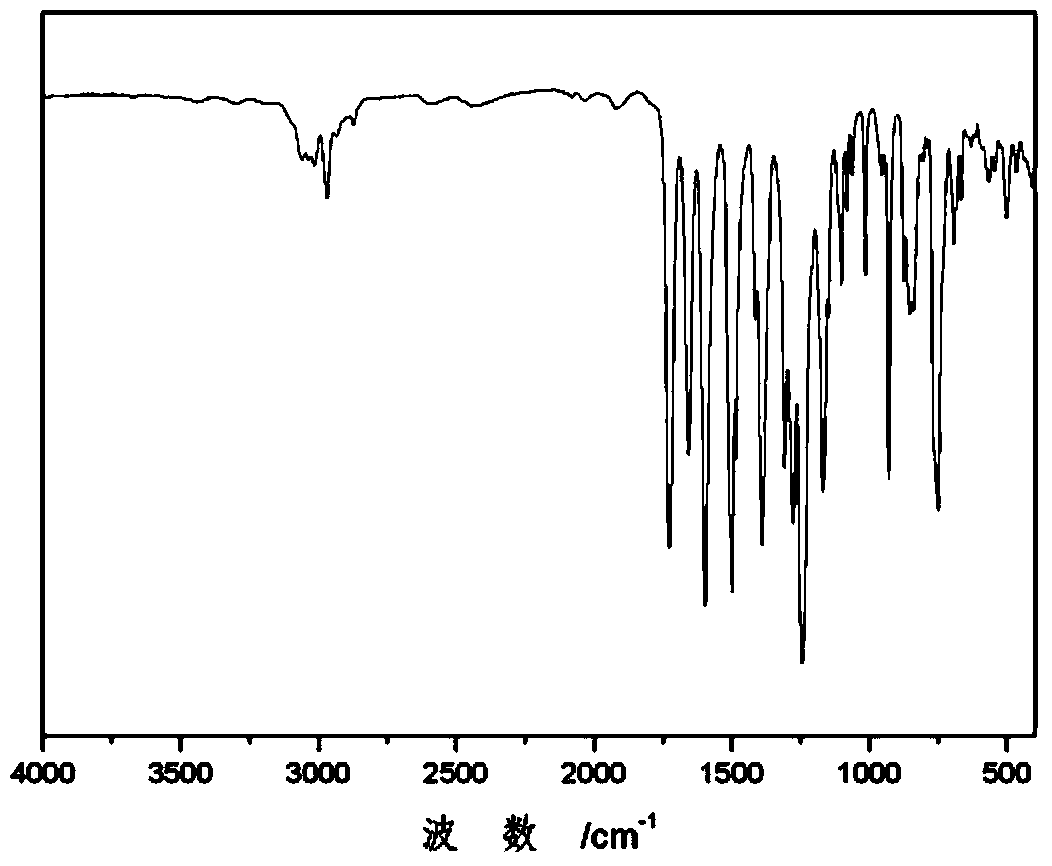

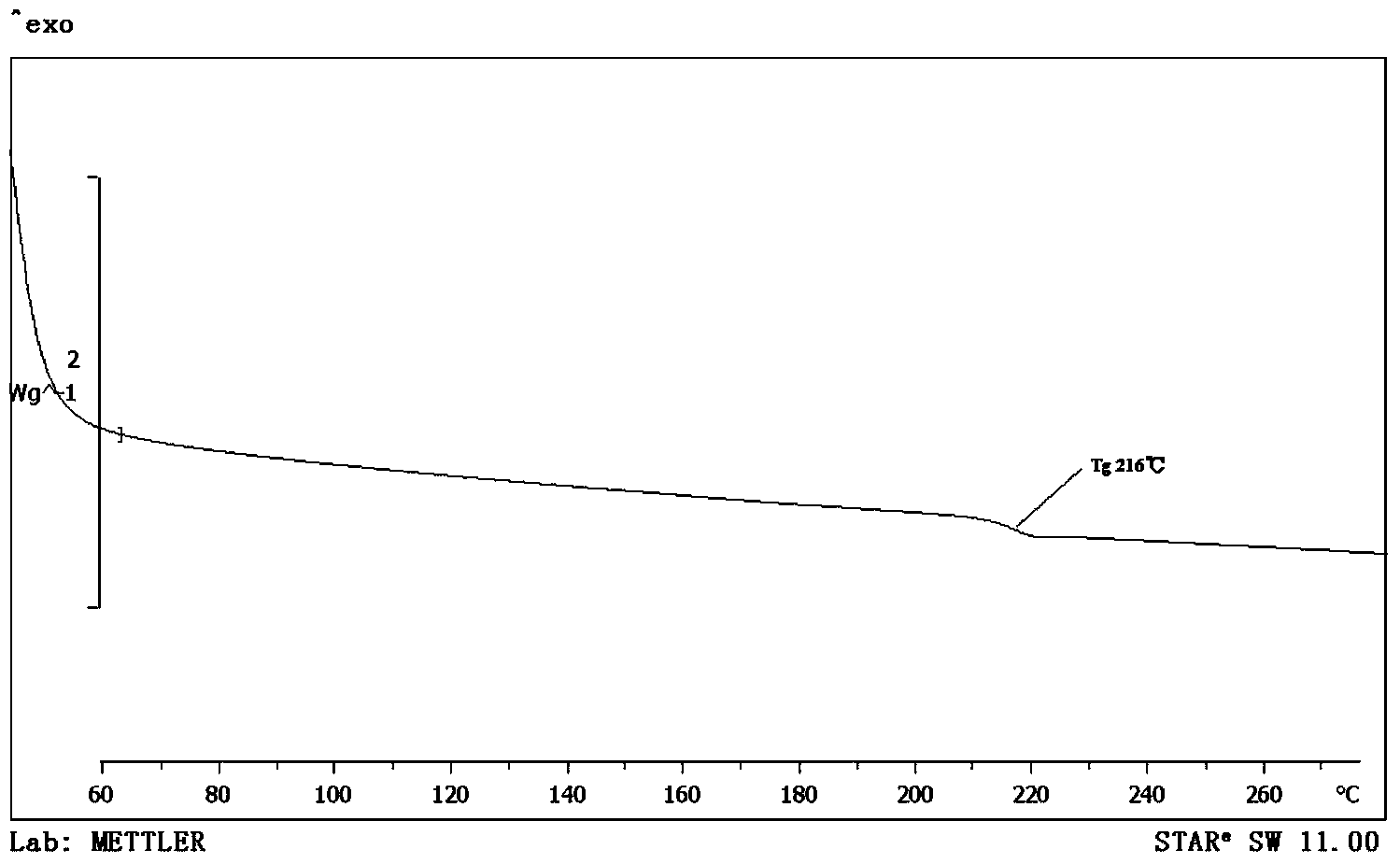

[0073] Experimental results prove that the modified polyaryletherketone represented by formula (I-a) obtained in Example 1 is soluble in N,N-dimethylformamide, N,N-dimethylacetamide and chloroform.

[0074] The ...

Embodiment 2

[0079] Add 1.487g (0.0099mol) benzimidazole thione (MBI), 0.032g (0.0001mol) phenolphthalein (PHI), 2.511g (0.01mol) dichlorobenzophenone (DCK) to a 100ml three-neck round bottom flask , 2.763g of potassium carbonate, 15g of N-cyclohexylpyrrolidone (CHP) and 12ml of toluene, heated to 130°C to azeotropically remove water, keep warm for 2.5h, raise the temperature to remove toluene, continue heating to 185°C, react for 3h, cool down, add 20ml of N , diluted with N-dimethylacetamide, precipitated in a mixed solution of ethanol and water, filtered the precipitate, extracted it with deionized water for 12 hours in a Soxhlet extractor, removed inorganic salts and reaction solvents, and dried to obtain the formula ( The modified polyaryletherketone shown in I-b) has a yield of 92.5%, and its reaction formula is as follows:

[0080]

[0081] Experimental results prove that the modified polyaryletherketone represented by formula (I-b) obtained in Example 2 is soluble in N,N-dimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Thermogravity temperature | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com