Polymer swollen microparticles for drilling fluid and preparation method thereof

A polymer and particle technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as unavailability of fluid loss control agents, improve the ability of stabilizing wellbore, strong formation adaptability, and reduce water loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

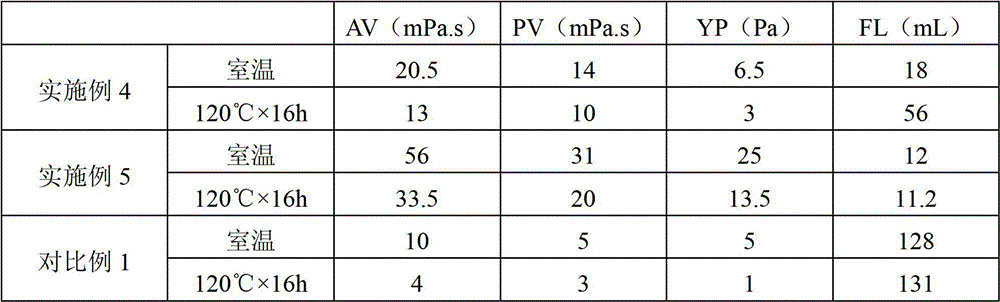

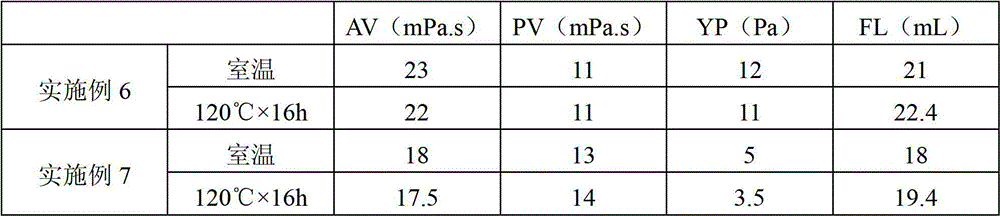

Examples

Embodiment 1

[0022] Add water and 20Kg of sodium hydroxide into the reaction kettle, stir evenly and cool to room temperature, then add 150Kg of sodium methacryl sulfonate, after it is completely dissolved, transfer it to a mixing kettle, add 600Kg of acrylamide under stirring, and wait until it is completely dissolved , add 100Kg of acrylic acid, stir evenly; put the mixed solution into the polymerization kettle, adjust the pH value of the polymerization system to 9.5 with aqueous sodium hydroxide solution, control the temperature at 20°C, add potassium persulfate and tetramethylethylenediamine aqueous solution to initiate A total of 2Kg of the agent was used to initiate the reaction, and the polymerization reaction was maintained for 1.5h; then 100Kg of epichlorohydrin was added, the temperature was controlled at 50°C, and the crosslinking reaction was maintained for 2h. After the polymerized jelly was cut and granulated, it was sent to the drying room. Dry at 105°C, and then pulverize to...

Embodiment 2

[0024] Add water and 18Kg of sodium hydroxide into the reaction kettle, stir evenly and cool to room temperature, then add 50Kg of sodium styrene sulfonate, after it is completely dissolved, transfer it to a mixing kettle, add 350Kg of acrylamide under stirring, and after it is completely dissolved, Add 60Kg of acrylic acid and stir evenly; put the mixed solution into the polymerization kettle, adjust the pH value of the polymerization system to 11 with potassium hydroxide aqueous solution, and control the temperature at 40°C, add hydrogen peroxide and ferrous chloride aqueous solution initiator for a total of 0.5 Kg initiates the reaction and maintains the polymerization reaction for 3 hours; then adds 100Kg of N,N'-methylenebisacrylamide, controls the temperature at 60°C, and maintains the cross-linking reaction for 4 hours. drying room, drying at 110°C, and then crushing to obtain polymer swollen particles.

Embodiment 3

[0026] Add water and 15Kg of sodium hydroxide into the reaction kettle, stir evenly and cool to room temperature, then add 80Kg of potassium isoprene sulfonate, after it is completely dissolved, transfer it to a mixing kettle, add 400Kg of acrylamide under stirring, and wait until it is completely dissolved Finally, add 80Kg of acrylic acid and stir evenly; put the mixed solution into the polymerization kettle, adjust the pH value of the polymerization system to 10 with potassium hydroxide aqueous solution, control the temperature at 50°C, add ammonium persulfate and sodium bisulfite aqueous solution initiator A total of 1Kg was used to initiate the reaction, and the polymerization reaction was maintained for 2 hours; then 80Kg of ethylene glycol diacrylate was added, the temperature was controlled at 60°C, and the cross-linking reaction was maintained for 5 hours. Dry at 120°C, and then pulverize to obtain polymer swollen particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com