Dental implant and preparation method thereof

A dental implant, titanium-based technology, applied in dentistry, dental implants, dental restorations, etc., can solve the problems of low strength of the film layer, poor bonding strength between the film and the matrix, fatigue damage due to stress, etc., to achieve low cost, Excellent osteogenic differentiation induction ability and the effect of enhancing the strength of the membrane layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

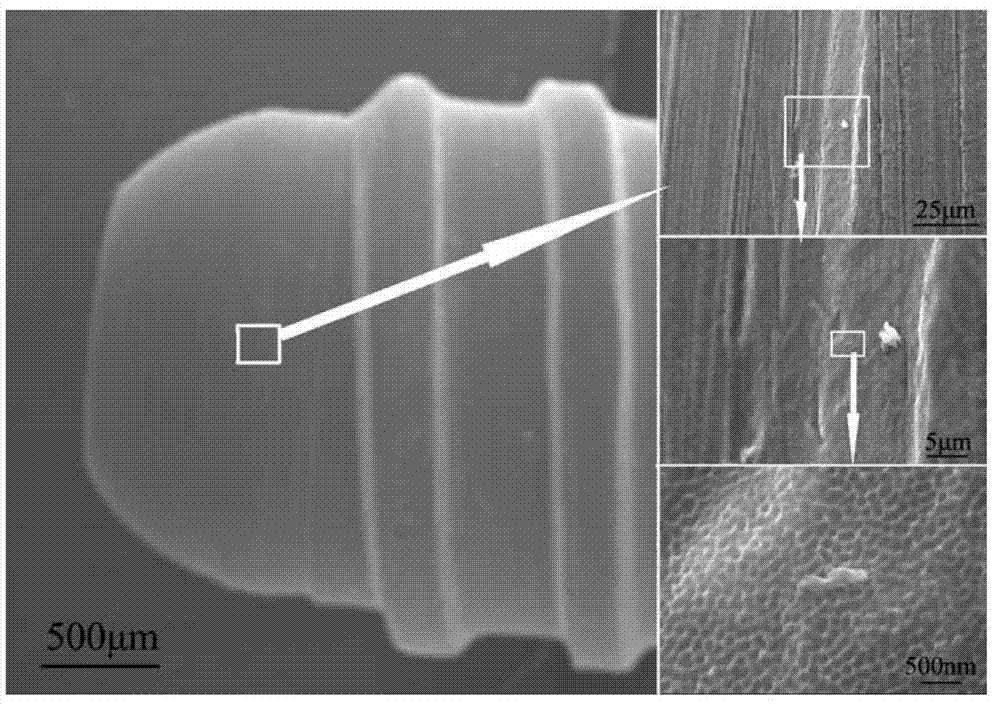

[0032] (1) Preparation of dental implant matrix

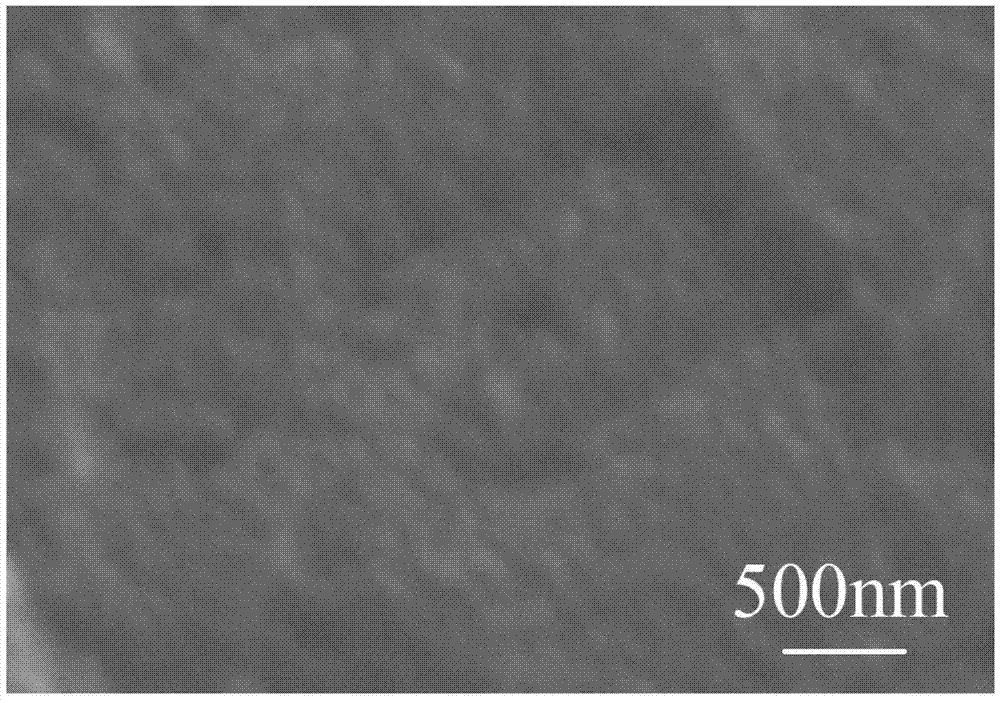

[0033] The common processing methods that can be used to process dental implant substrates from titanium substrates (such as medical pure titanium or titanium alloys) will not be described in detail here. It should be understood that as long as the dental implant substrates can be obtained, the processing methods include in the present invention. Dental implants are then surface polished, cleaned and pretreated. Likewise, the polishing and cleaning treatment of the titanium substrate is not particularly limited, and known methods can be used, and this pretreatment is not essential to the present invention. The surface topography of pretreated dental implants can be found in figure 1 , it can be seen from the figure that there is no obvious microstructure on the surface of the dental implant.

[0034] (2) Preparation of anodic oxidation electrolyte

[0035] The electrolyte used may be ethylene glycol solution of ammonium flu...

Embodiment 1

[0050] (1) Select pure titanium to process into dental implants;

[0051] (2) After polishing the surface of the implant, ultrasonically clean it with acetone, alcohol and deionized water for 30 minutes to obtain a clean and uniform surface;

[0052] (3) Preparation of anodic oxidation electrolyte: ethylene glycol as solvent, prepare ethylene glycol solution of 0.25% ammonium fluoride and 1% pure water;

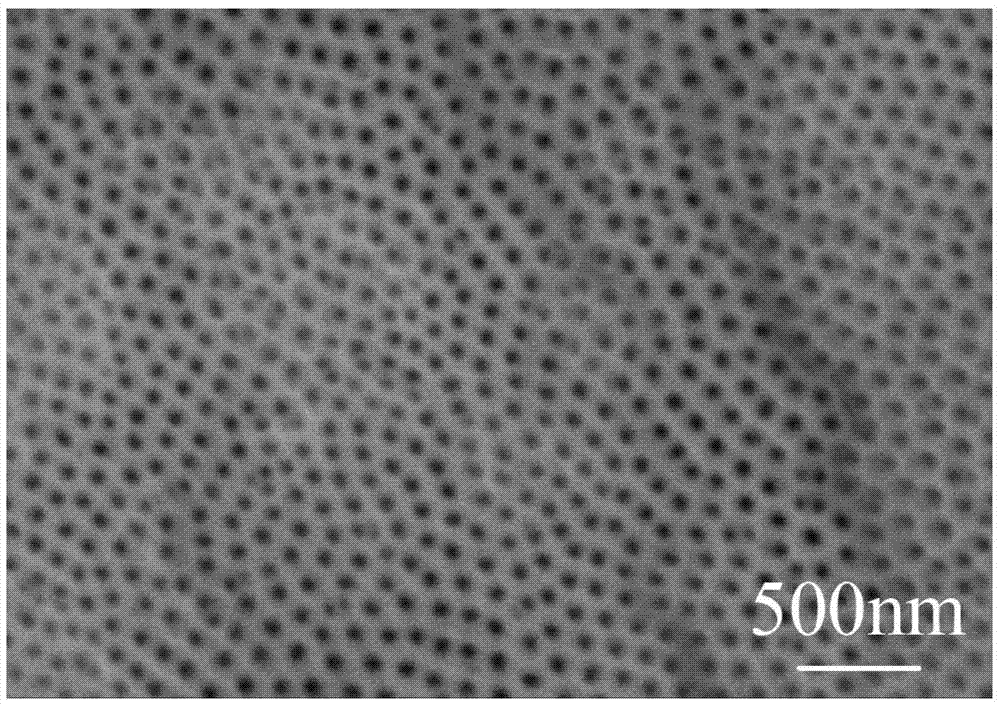

[0053] (4) Preparation of regular titanium oxide nanotube films by anodic oxidation method: Constant voltage direct current anodic oxidation technology is adopted, dental implants are used as anodes, graphite electrodes or platinum electrodes are used as cathodes, and they are placed in the electrolyte prepared in the previous step; working voltage is 50V, the oxidation time is 2 hours, and the reaction temperature is room temperature;

[0054] (5) Prepare the electrolyte for electrochemical stripping: deionized water is used as the solvent, and a dilute sulfuric acid soluti...

Embodiment 2

[0066] (1) Select medical titanium to process into dental implants;

[0067] (2) After polishing the surface of the implant, ultrasonically clean it with acetone, alcohol and deionized water for 30 minutes to obtain a clean and uniform surface;

[0068] (3) Preparation of anodic oxidation electrolyte: ethylene glycol as solvent, prepare ethylene glycol solution of 0.25% ammonium fluoride and 1% pure water;

[0069] (4) Preparation of regular titanium oxide nanotube films by anodic oxidation method: Constant voltage direct current anodic oxidation technology is adopted, dental implants are used as anodes, graphite electrodes or platinum electrodes are used as cathodes, and they are placed in the electrolyte prepared in the previous step; working voltage is 60V, the oxidation time is 1 hour, and the reaction temperature is room temperature;

[0070] (5) Prepare the electrolyte for electrochemical stripping: deionized water is used as the solvent, and a dilute sulfuric acid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com