Method for preparing electrophoretic particles by using organic pigment

A particle and electrophoretic display technology, which is applied in organic dyes, dyed organic silicon compounds, dyed polymer organic compounds, etc., can solve the problems of uneven particle shape, cumbersome operation, and high quality requirements of organic pigments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

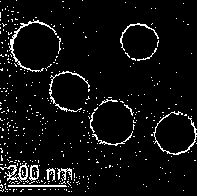

[0072] Example 1: Using organic bispyrrole DPP organic pigments as raw materials to prepare red electrophoretic particles

[0073] (1) Take a 2L clean three-neck flask, add 20g of organic bispyrrole DPP pigment and 550g of ethanol into it, and place it in a water bath, install agitator, condenser, and thermometer, stir and disperse at 900rpm for 1h, Add 46g of ammonia water and 30g of distilled water to the slurry, keep the stirring speed constant, stir for 30min, keep the room temperature and stirring speed constant, add 23g of TEOS (dissolved in 50g of absolute ethanol) with a peristaltic pump, and finish adding at a constant speed within 2h. After the addition, the temperature was raised to 55 degrees, and the stirring speed was kept constant. After 16 hours of reaction, the temperature was naturally lowered without heating, and the reaction was continued for 4 hours.

[0074] After the reaction time of the above step (1) is up, directly add the solution containin...

Embodiment 2

[0077] Example 2: Using β-type copper phthalocyanine blue organic pigment as raw material to prepare blue electrophoretic particles

[0078] (1) Put 10g of β-type copper phthalocyanine blue into a 1L clean three-neck bottle, add 30g of water, put it on and stir, stir and disperse at 350rpm for 10min, then add 23g of ammonia water, and stir again for 10min; then add 250g of absolute ethanol , uniformly disperse under stirring, stir for 30min; measure 23g of TEOS and 50g of ethanol, use a peristaltic pump to add dropwise, and add them to the there-necked flask within 2h. When adding, keep the temperature at room temperature. After the addition, raise the temperature to 55°C for 48h , after the reaction time is up, carry out natural cooling;

[0079] (2) After the reaction time of the above step (1) is up, directly add 30 g of diethylenetriaminopropyltrimethoxysilane, stir at 35° C. for 8 h, and centrifuge after the stirring time is up. Then wash twice with absolute et...

Embodiment 3

[0082] Example 3: Using organic quinophthalone pigments as raw materials to prepare yellow electrophoretic particles

[0083] (1) Take 20g of organic quinophthalone pigment and place it in a 1L clean three-necked bottle, add 450g of absolute ethanol, disperse evenly at 350rpm, and stir for 30min; then add 30g of water, stir and disperse for 10min, add 25.3g of ammonia water, and stir for 10min again After getting 69.3g of TEOS mixed with 46.5ml ethanol, use a peristaltic pump to add it dropwise, and add it into the there-necked flask at a constant speed within 2 hours. After that, carry out natural cooling;

[0084] (2) After the reaction time of the above step (1) is up, directly add N-[3-(trimethoxysilyl)propyl]-N'-(4-vinylbenzyl)ethylenediamine hydrochloride solution (containing solute 54g), at 35 DEG C, stir 8h, after stirring time is up, carry out centrifugation. Then wash twice with absolute ethanol, centrifuge to remove the upper layer solution, then wash tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com