Preparation method of a ternary (sb1-xbix)2se3 nanowire with adjustable composition

A sb1-xbix and nanowire technology, applied in the field of material science, can solve problems such as low spectral responsivity, many nanowire defects, and poor crystallization, and achieve the effects of simple preparation process, convenient regulation, and easy regulation of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

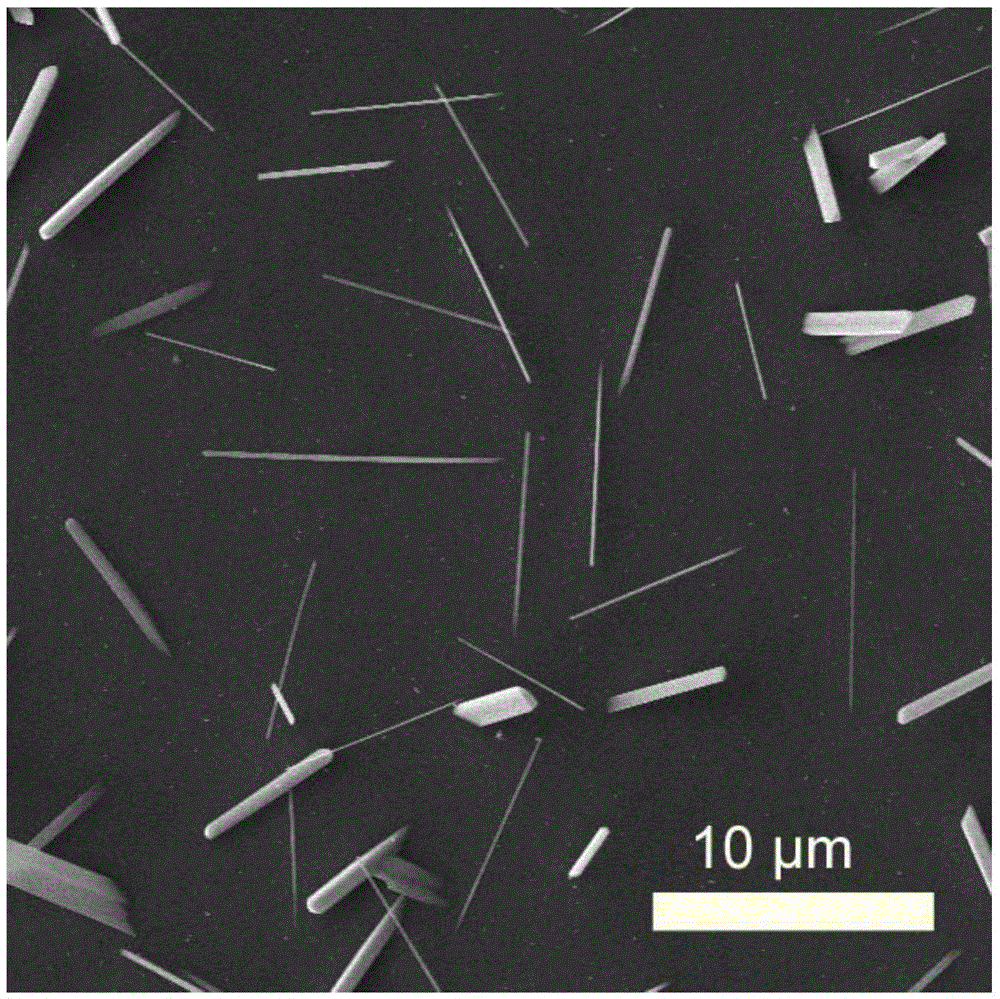

[0027] In a typical embodiment of the present invention, the preparation method comprises: firstly Sb 2 Se 3 Powder and Bi 2 Se 3 The powder is mixed in a certain proportion as the growth source and placed in the center of the quartz tube of the tube furnace for chemical vapor deposition. The silicon wafer with gold particles is placed at the downstream position of the quartz tube airflow and the quartz tube is sealed; the quartz tube is sealed with a mechanical pump. Exhaust the oxygen in the tube as much as possible, then fill it with a certain flow rate of high-purity argon as a carrier gas, and combine with the vacuum mechanical pump to maintain a certain vacuum degree in the quartz tube; react at a certain temperature for a period of time; after the reaction is completed, it can be cooled at room temperature get (Sb 1-x Bi x ) 2 Se 3 Nanowires (x=0~0.88). This method uses a simple chemical vapor deposition method, and by changing the ratio of growth sources or grow...

Embodiment 1

[0040] (1) Preparation of silicon wafers with colloidal gold particles: Submerge the silicon wafers with acetone, ethanol and deionized water for 10 minutes, and then dry them with nitrogen; immerse the cleaned silicon wafers in 0.1wt% poly-L- Lysine aqueous solution for 1 minute, then rinse with deionized water to positively charge the surface of the silicon wafer; then immerse the silicon wafer in a colloidal gold liquid with a diameter of 10nm for 1 minute, then rinse with deionized water, and finally blow dry with nitrogen , to obtain a silicon wafer with gold particles attached to the surface;

[0041] (2) Sb with a mass of 10 mg 2 Se 3 The powder is placed in the center of the quartz tube; the silicon wafer with gold particles attached is placed at the downstream position of the quartz tube airflow and the quartz tube is sealed; the inner chamber of the quartz tube is pumped and filtered to below 10mTorr with a mechanical pump, and then filled with an appropriate amount...

Embodiment 2

[0045] (1) Preparation of silicon wafers with colloidal gold particles: Submerge the silicon wafers with acetone, ethanol and deionized water for 10 minutes, and then dry them with nitrogen; immerse the cleaned silicon wafers in 0.1wt% poly-L Acid solution for 1 minute, then rinse with deionized water to make the surface of the silicon wafer positively charged; then immerse the silicon wafer in a colloidal gold liquid with a diameter of 10nm for 1 minute, then rinse with deionized water, and finally blow dry with nitrogen. Obtain a silicon wafer with gold particles attached to the surface;

[0046] (2) Sb with a mass of 7.5mg 2 Se 3 Powder with 2.5mg of Bi 2 Se 3 The powder is mixed and placed in the center of the quartz tube; the silicon wafer with gold particles attached is placed at the downstream position of the quartz tube airflow and the quartz tube is sealed; the inner chamber of the quartz tube is pumped and filtered to below 10mTorr with a mechanical pump, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com