Preparation method for chitosan-based electrostatic spinning combined wound dressing

A technology of electrospinning and wound dressing, which is applied in the field of preparation of chitosan-based electrospinning composite wound dressings, can solve the problems of increasing the difficulty of adding pure chitosan nanofiber membranes, high viscosity of the solution, and low solubility. Achieve the effect of relieving stress, good biocompatibility, and eliminating nervous tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

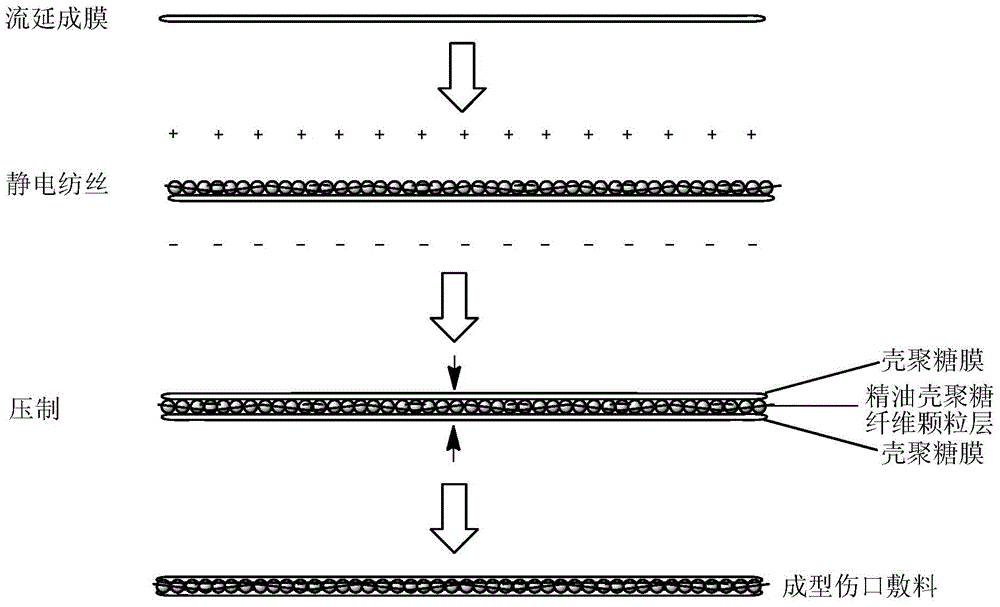

[0029] A preparation method of chitosan-based electrospinning composite wound dressing, comprising the steps of:

[0030] (1) Mix 0.5ml tea tree essential oil and 0.1g lecithin in 0.5ml water and stir evenly, and ultrasonically disperse and degas to obtain an essential oil emulsion;

[0031] (2) 0.75g chitosan (viscosity average molecular weight 5.0×10 5 , the degree of deacetylation is 80-85%) was dissolved in 50ml of 90% acetic acid solution, 1ml of glycerin was added as a plasticizer, 1ml of essential oil emulsion was added, and stirred at room temperature until completely dissolved to obtain a spinning solution;

[0032] (3) Dissolve 1g of chitosan in 50ml of 2% acetic acid solution, add 1ml of glycerin as a plasticizer, stir at room temperature until completely dissolved to obtain a film-forming liquid, and use the cast film-forming method to prepare a chitosan film, uncover next standby;

[0033] (4) Coat the chitosan film on the electrospinning receiving plate, extrac...

Embodiment 2

[0036] A preparation method of chitosan-based electrospinning composite wound dressing, comprising the steps of:

[0037] (1) Mix 1ml of tea tree essential oil and 0.2g of lecithin in 1ml of water and stir evenly, and ultrasonically disperse and degas to obtain an essential oil emulsion;

[0038] (2) 1.5g chitosan (viscosity average molecular weight 5.0×10 5 , the degree of deacetylation is 80-85%) was dissolved in 50ml of 90% acetic acid solution, 2ml of glycerin was added as a plasticizer, 2ml of essential oil emulsion was added, and stirred at room temperature until completely dissolved to obtain a spinning solution;

[0039] (3) Dissolve 1.25g of chitosan in 50ml of 2% acetic acid solution, add 2ml of glycerin as a plasticizer, stir at room temperature until completely dissolved to obtain a film-forming liquid, and use the cast film-forming method to prepare a chitosan film. Take off the spare;

[0040] (4) Coat the chitosan film on the electrospinning receiving plate, e...

Embodiment 3

[0043] A preparation method of chitosan-based electrospinning composite wound dressing, comprising the steps of:

[0044] (1) Mix 0.75ml tea tree essential oil and 0.15g lecithin in 0.75ml water and stir evenly, and ultrasonically disperse and degas to prepare essential oil emulsion;

[0045] (2) 1g chitosan (viscosity average molecular weight 5.0×10 5 , the degree of deacetylation is 80-85%) was dissolved in 50ml of 90% acetic acid solution, 1.5ml of glycerin was added as a plasticizer, 1.5ml of essential oil emulsion was added, and stirred at room temperature until completely dissolved to obtain a spinning solution;

[0046] (3) Dissolve 0.75g of chitosan in 50ml of 2% acetic acid solution, add 0.75ml of glycerin as a plasticizer, stir at room temperature until completely dissolved to obtain a film-forming solution, and use the cast film-forming method to prepare a chitosan film , take off the spare;

[0047] (4) Cover the chitosan film on the electrospinning receiving pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com