Method for preparing zirconium silicate whisker by employing non-hydrolytic sol-gel technology combined with molten-salt growth method

A technology of zirconium silicate whisker and zirconium silicate, which is applied in the directions of self-gelling state, chemical instruments and methods, and self-melting solvent melt, etc., can solve the problem of high price, increase the difficulty of operation, and is not suitable for mass production Use and other problems to achieve the effect of low synthesis temperature, broad market space, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

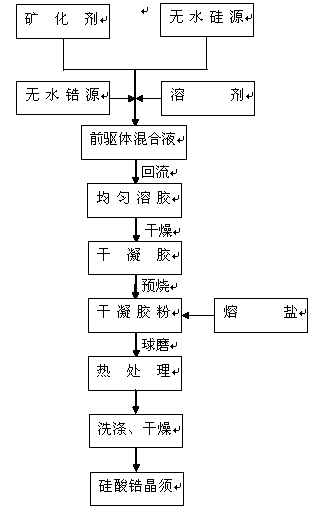

Method used

Image

Examples

Embodiment 1

[0023] with anhydrous ZrCl 4 (industrial pure), Si(OC 2 h 5 ) 4 (chemically pure) is the reaction precursor, LiF (chemically pure) is the mineralizer, absolute ethanol (chemically pure) is the solvent, Na 2 MoO 4 (chemically pure) is a molten salt. First weigh 0.280 g LiF and put it in a dry Erlenmeyer flask, then add 8 ml Si(OC 2 h 5 ) 4 , 7.040 g ZrCl 4 , 30 ml of absolute ethanol, heated and magnetically stirred for 20 min to obtain a zirconium silicate precursor mixed solution; then put the mixed solution in an oil bath at 110 ℃ to condense and reflux for 24 h to obtain a transparent zirconium silicate sol; place the sol in Dry in an oven at 100 °C for 24 h to obtain zirconium silicate xerogel, then pre-fire it in an electric furnace at 400 °C and keep it warm for 30 min to obtain zirconium silicate xerogel powder; mix xerogel powder with Na 2 MoO 4 The mixture was ball-milled at a mass ratio of 1:4, placed in an alumina crucible, heat-treated at 900 °C and kept ...

Embodiment 2

[0025] With anhydrous Zr(OC 3 h 7 ) 4 (industrial pure), Si(OC 2 h 5 ) 4 (chemically pure) is the precursor, LiF (chemically pure) is the mineralizer, anhydrous n-butanol (chemically pure) is the solvent, and LiF (chemically pure) is the solvent. 2 MoO 4 for molten salt. The technological process and experimental conditions used to prepare zirconium silicate whiskers are the same as in Example 1, except that the amount of LiF used is 0.187 g, the amount of anhydrous n-butanol is 25 ml, the pre-calcination temperature is 300 ° C for 60 min, and the heat treatment temperature is 750 °C. ℃ for 3 h.

Embodiment 3

[0027] with anhydrous ZrCl 4 (industrial pure), Si(OC 2 h 5 ) 4 (chemically pure) is the precursor, LiCl (chemically pure) is the mineralizer, anhydrous dichloromethane (chemically pure) is the solvent, Na 2 MoO 4 for molten salt. The process flow and experimental conditions used to prepare zirconium silicate whiskers are the same as in Example 1, except that the amount of LiCl is 0.458 g, the mass ratio of dry gel powder to molten salt is 1:2, the pre-calcination temperature is 800 °C and the temperature is kept for 60 min. The temperature was kept at 1000 °C for 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com