Preparation method of Cu-Zn-In-S quantum dot luminescent thin film

A cu-zn-in-s, quantum dot luminescent technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of quantum dot agglomeration, increased difficulty, cumbersome synthesis process, etc., and achieves mild synthesis temperature and convenient operation , the effect of simple synthesis equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

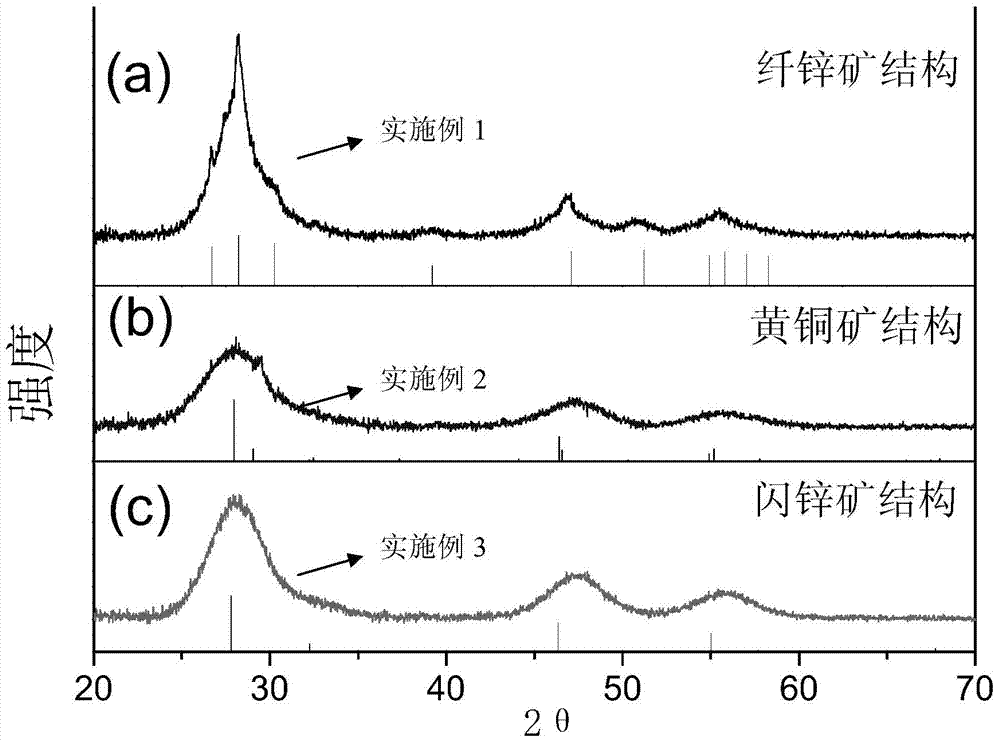

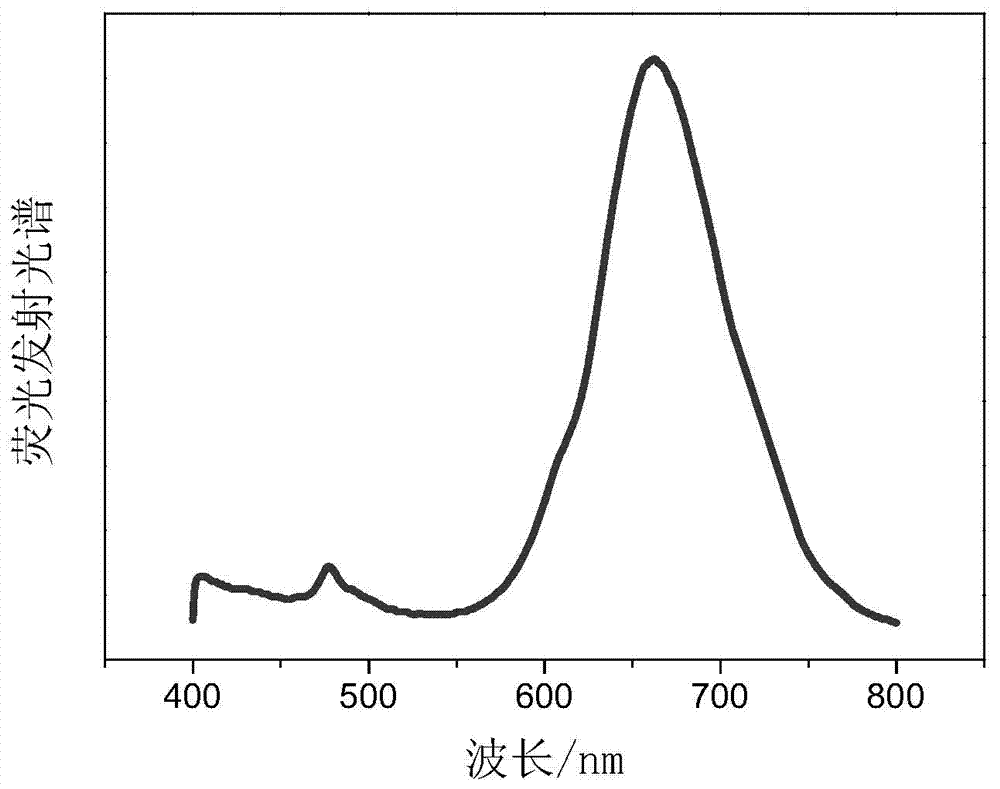

Embodiment 1

[0029] In the first step, weigh 3.96mg (0.04mmol) CuCl, 27.26mg (0.2mmol) ZnCl 2 , 44.24mg (0.2mmol) InCl 3 Place in a three-necked bottle, and add 0.2mmol oleic acid, 2mmol dodecanethiol, 8ml octadecene.

[0030] In the second step, under the conditions of magnetic stirring and argon protection, heat the mixed solution to 180°C to make CuCl, ZnCl 2 and InCl 3 Completely dissolve to form a clear and transparent solution. At this time, inject 4mL sulfur powder-oleylamine solution (sulfur powder concentration is 0.2mol / L) into the solution, adjust the temperature to 160°C, maintain the temperature, and let the reaction proceed for 90min to prepare Cu -Zn-In-S quantum dot solution.

[0031] In the third step, remove the heat source and cool to room temperature naturally, take 0.5ml of Cu-Zn-In-S quantum dot stock solution, add 4ml of absolute ethanol, and perform centrifugal purification on the Cu-Zn-In-S quantum dot stock solution.

[0032] The fourth step is to mix the puri...

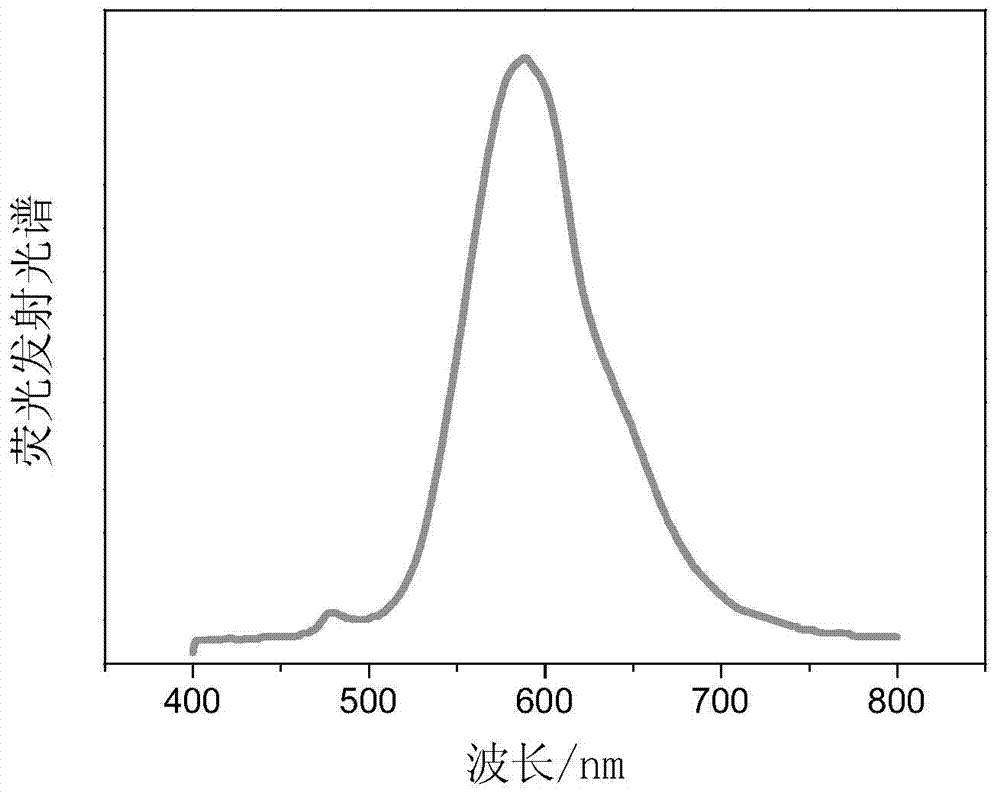

Embodiment 2

[0037] The first step, weigh 2.48mg (0.025mmol) CuCl, 51.11mg (0.375mmol) ZnCl 2 , 44.24mg (0.2mmol) InCl 3 Place in a three-necked bottle, and add 0.2mmol oleic acid, 2mmol dodecanethiol, 8ml octadecene.

[0038] In the second step, under the conditions of magnetic stirring and argon protection, heat the mixed solution to 190°C to make CuCl, ZnCl 2 and InCl 3 Completely dissolve to form a clear and transparent solution. At this time, inject 4mL of sulfur powder-oleylamine solution (sulfur powder concentration is 0.2mol / L) into the solution, adjust the temperature to 170°C, maintain the temperature, and let the reaction proceed for 90min to prepare Cu -Zn-In-S quantum dot solution.

[0039] In the third step, remove the heat source and cool to room temperature naturally, take 0.5ml of Cu-Zn-In-S quantum dot stock solution, add 4ml of absolute ethanol, and perform centrifugal purification on the Cu-Zn-In-S quantum dot stock solution.

[0040] The fourth step is to mix the p...

Embodiment 3

[0045] In the first step, weigh 1.89mg (0.019mmol) CuCl, 240.89mg (0.381mmol) Zn (St) 2 , 44.24mg (0.2mmol) InCl 3 Place in a three-necked bottle, and add 0.2mmol oleic acid, 2mmol dodecanethiol, 8ml octadecene.

[0046] In the second step, under the conditions of magnetic stirring and argon protection, heat the mixed solution to 200°C to make CuCl, ZnCl 2 and InCl 3 Dissolve completely to form a clear and transparent solution. At this time, inject 4mL of sulfur powder-oleylamine solution (sulfur powder concentration is 0.2mol / L) into the solution, adjust the temperature to 220°C, maintain the temperature, and let the reaction proceed for 90min to prepare Cu -Zn-In-S quantum dot solution.

[0047] In the third step, remove the heat source and cool down to room temperature naturally, take 0.5ml Cu-Zn-In-S quantum dot stock solution, add absolute ethanol, and perform centrifugal purification treatment on the Cu-Zn-In-S quantum dot stock solution.

[0048] The fourth step is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com