Method for preparing active factor sustained-releasing PELA (Percutaneous endovenous laser ablation) microsphere scaffold bone repairing material

An active factor, PLA-PEG-PLA technology, applied in medical science, prosthesis, etc., can solve the problems of high brittleness, strong bone conduction ability, and inability to release strong chemotaxis-induced osteogenesis in a sustained manner, and achieve tissue phase Good capacity, simple preparation, no immunogenic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

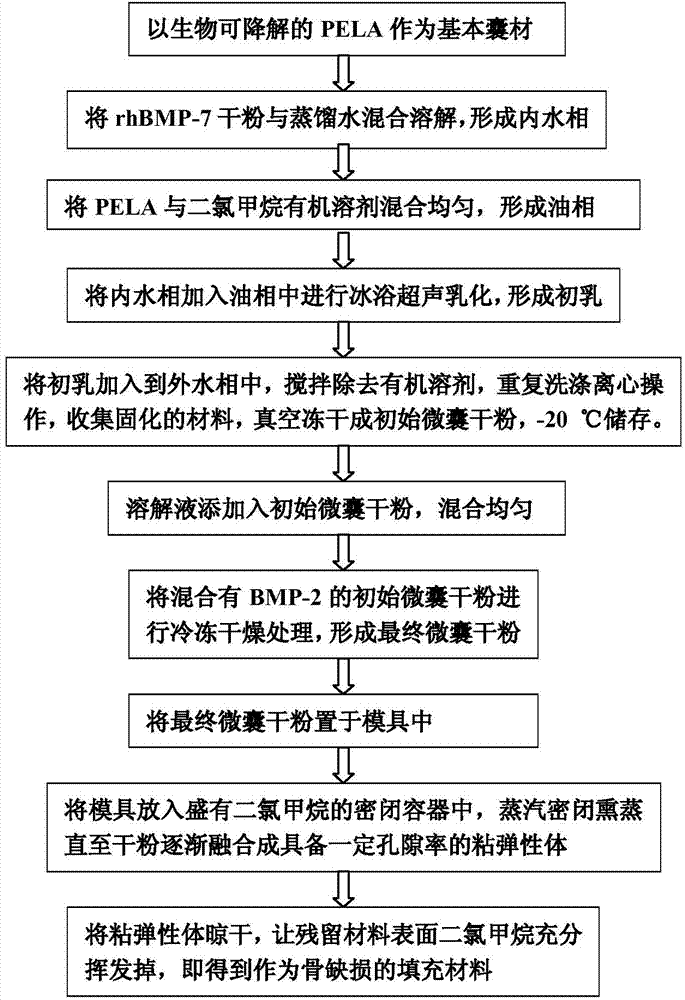

Image

Examples

Embodiment 1

[0038] 1. Select capsule material

[0039] The biodegradable PLA-PEG-PLA tri-block copolymer is used as the basic capsule material, and the molecular weight of the polymer PEG in the tri-block copolymer accounts for 10% of the total polymer molecular weight;

[0040] 2. Preparation of PELA / rhBMP-7 initial drug-loaded microcapsules

[0041] First, 1ug of rhBMP-7 dry powder was dissolved in 150ul distilled water, and mixed uniformly to form an inner aqueous phase; then, 240mg of PLA-PEG-PLA triblock copolymer with a total molecular weight of 20,000Da was placed in distilled water containing 0.5% span-20 Make an oil phase with 4ml of methyl chloride organic solvent; then add the prepared inner water phase into the oil phase for ultrasonic emulsification in an ice bath to form colostrum; finally, add the colostrum to the outer water containing 0.5% PVA (polyvinyl alcohol) In the phase, stir at 800 rpm for 30 minutes, remove the organic solvent, centrifuge, wash with distilled w...

Embodiment 2

[0048] 1. Select capsule material

[0049] The biodegradable PLA-PEG-PLA tri-block copolymer is used as the basic capsule material, and the molecular weight of the polymer PEG in the tri-block copolymer accounts for 20% of the total polymer molecular weight;

[0050] 2. Preparation of PELA / rhBMP-7 initial drug-loaded microcapsules

[0051] First, 1ug of rhBMP-7 dry powder was dissolved in 200ul distilled water, and mixed uniformly to form an inner aqueous phase; then, 280mg of PLA-PEG-PLA triblock copolymer with a total molecular weight of 20000Da was placed in a distilled water solution containing 0.5% span-20 Make an oil phase with 4ml of methyl chloride organic solvent; then add the prepared inner water phase into the oil phase for ultrasonic emulsification in an ice bath to form colostrum; finally, add the colostrum to the outer water containing 0.5% PVA (polyvinyl alcohol) In the phase, stir at 800rpm for 30 minutes, remove the organic solvent, centrifuge, wash with di...

Embodiment 3

[0057] 1. Select capsule material

[0058] The biodegradable PLA-PEG-PLA tri-block copolymer is used as the basic capsule material, and the molecular weight of the polymer PEG in the tri-block copolymer accounts for 30% of the total polymer molecular weight;

[0059] 2. Preparation of PELA / rhBMP-7 initial drug-loaded microcapsules

[0060] First, 1ug of rhBMP-7 dry powder was dissolved in 250ul of distilled water, and mixed uniformly to form an inner aqueous phase; then, 320mg of PLA-PEG-PLA triblock copolymer with a total molecular weight of 20,000Da was placed in distilled water containing 0.5% span-20 Make an oil phase with 4ml of methyl chloride organic solvent; then add the prepared inner water phase into the oil phase for ultrasonic emulsification in an ice bath to form colostrum; finally, add the colostrum to the outer water containing 0.5% PVA (polyvinyl alcohol) In the phase, stir at 800rpm for 30 minutes, remove the organic solvent, centrifuge, wash with distilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com