Preparation method for silicon-carbon composite nano tube array

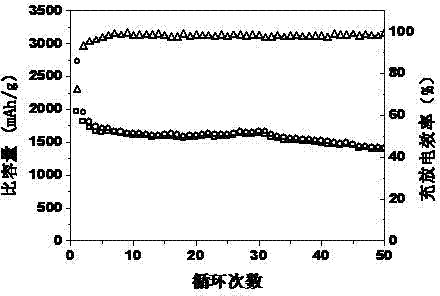

A nanotube array, silicon-carbon composite technology, applied in the field of lithium-ion batteries, can solve the problems of film and silicon cracking and pulverization, difficulty in large-scale production, poor cycle performance, etc., to achieve uniform size, controllable tube length, ratio of High volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

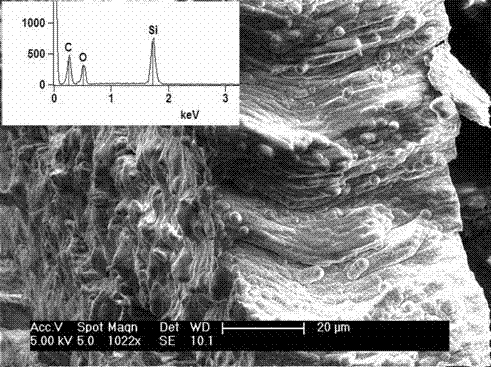

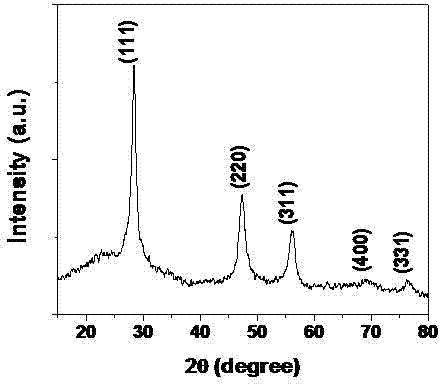

[0029] A porous anodized aluminum template with a pore size of 200 nm was placed in a corundum ark, placed in the heating zone of a tube furnace, and high-purity argon gas was passed through at a flow rate of 100 sccm for 2 hours, and the temperature was programmed to rise to 800 °C at 10 °C per minute. Acetylene gas with a flow rate of 50 sccm was injected for 30 minutes, and the temperature was naturally lowered after 2 hours of heat preservation. During this process, acetylene was decomposed in the high-temperature gas phase, and carbon atoms were deposited on the inner wall of the pores of the porous anodized aluminum template to obtain a carbon nanotube array contained in the template.

[0030] The carbon nanotube array was placed in the corundum ark, placed in the heating zone of the tube furnace, and vacuumed to 5 Pa and 10 Pa with a mechanical pump and a diffusion pump in turn. -2Pa, the temperature is programmed to rise to 700°C at 10°C per minute, the diffusion pump i...

Embodiment 2

[0035] Place a porous anodized aluminum template with a pore size of 200nm in a corundum ark, put it into the heating zone of a tube furnace, and pass argon gas at a flow rate of 100 sccm for 2 hours, then heat up to 700°C at a rate of 10°C per minute. 50 sccm of acetylene gas for 20 minutes, keep warm for 2 hours and then cool down naturally. During this process, acetylene is decomposed in high-temperature gas phase, and carbon atoms are deposited on the inner wall of the porous anodized aluminum template pores to obtain carbon nanotube arrays contained in the template.

[0036] The carbon nanotube array was placed in the corundum ark, placed in the heating zone of the tube furnace, and vacuumed to 5 Pa and 10 Pa with a mechanical pump and a diffusion pump in turn. -2 Pa, the temperature was programmed to rise to 700°C at 10°C per minute, the diffusion pump was stopped, 100sccm of argon gas was introduced, the position of the butterfly valve was adjusted, the system pressure w...

Embodiment 3

[0041] A porous anodized aluminum template with a pore size of 200nm was placed in a corundum ark, placed in the heating zone of a tube furnace, and nitrogen gas was passed through at a flow rate of 50 sccm for 2 hours, and then the temperature was programmed to rise to 600°C at 10°C per minute, and the flow rate was 20 sccm of acetylene gas for 30 minutes, keep warm for 2 hours and then cool down naturally. During this process, acetylene is decomposed in high-temperature gas phase, and carbon atoms are deposited on the inner wall of the porous anodized aluminum template pores to obtain a carbon nanotube array contained in the template.

[0042] The carbon nanotube array was placed in the corundum ark, placed in the heating zone of the tube furnace, and vacuumed to 5 Pa and 10 Pa with a mechanical pump and a diffusion pump in turn. -2 Pa, the temperature was programmed to rise to 600°C at 10°C per minute, the diffusion pump was stopped, nitrogen gas of 100 sccm was introduced, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com