Low temperature organic malodorous gas treating system

A malodorous gas and treatment system technology, which is applied to the treatment of organic malodorous gas with a temperature lower than 5°C, and the field of low-temperature organic malodorous gas treatment system, can solve the problems of low malodorous gas treatment efficiency, environmental hazards, endocrine disorders, etc., and achieves elimination of unfavorable Influence, system structure is simple, the effect of guaranteeing the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

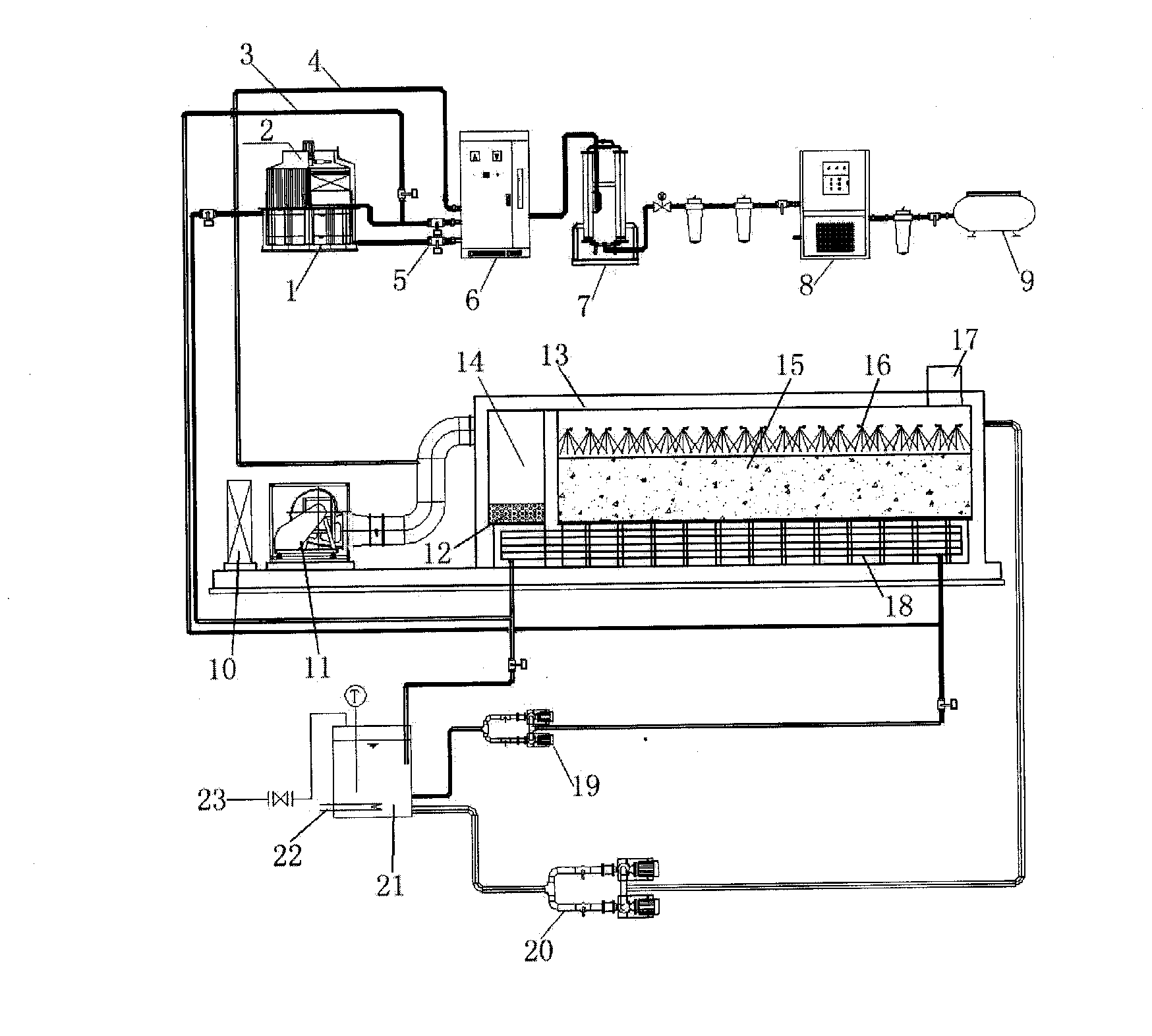

[0060] In the figure: 1. Cooling pool, 2. Cooling tower, 3. Ozone generator cooling water outlet pipe, 4. Ozone gas outlet pipe, 5. Ozone generator cooling water inlet valve, 6. Ozone generator, 7. Oxygen production Machine, 8. Cold dryer, 9. Air compressor, 10. Control cabinet, 11. Fan, 12. Ozone destruction catalyst layer, 13. Biological deodorization tower, 14. Ozone oxidation pre-reaction area, 15. Carbonaceous organisms Media filler, 16. Spray nozzle, 17. Air outlet, 18. Waste heat recovery device, 19. Heating circulating water pump, 20. Spray water pump, 21. Spray water tank, 22. Heating device, 23. Reclaimed water or tap water pipeline .

[0061] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0062] from figure 1 It can be seen that the low-temperature organic malodorous gas treatment system is composed of an odor collection system, an ozone generation system, an ozonation pre-reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Filling density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com