Method for preparing ruthenium trichloride with low-concentration complicated ruthenium-containing waste liquid

A ruthenium trichloride, low-concentration technology is applied in the field of preparing ruthenium trichloride from a low-concentration and complex ruthenium-containing waste liquid, which can solve the problems of shortened reaction time, many impurity elements, and low ruthenium enrichment rate, and achieves ruthenium enrichment. High efficiency, simple process and less distillation times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

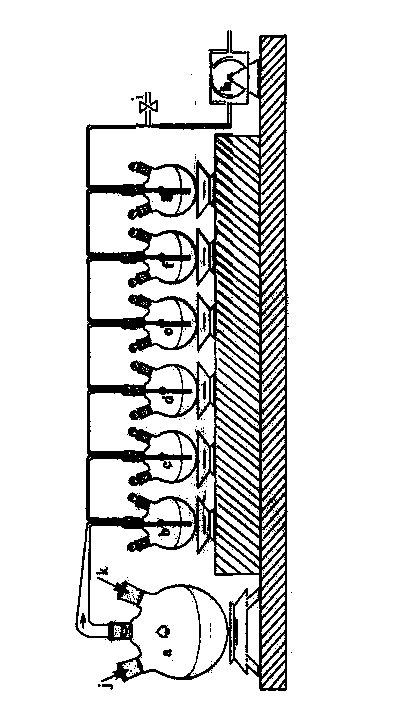

Image

Examples

Embodiment 1

[0015] Measure 100Kg of low-concentration complex ruthenium-containing waste liquid and add it to a 500L porcelain jar (the ruthenium content is 9.53‰ after analysis), slowly add 5Kg of hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid or two mixed acids under stirring, and then add A precipitating agent in 1906g ammonium sulfide, hydrazine hydrate, thiourea, sodium borohydride, sodium hydroxide, heated to boiling 1h to stop heating, diluted with water to 200L, unloaded, routinely filtered, washed, dried to obtain 1115g ruthenium slag ( After analyzing the ruthenium content 84.29%), the yield of ruthenium in the waste liquid is 98.62%.

[0016] Get 300g of ruthenium slag and put it into reactor a, add 1.5L mass fraction of 20–40% NaOH solution, add 2L deionized water to b and c, add RuO 4 Add 2.5L of 2–10mol / L hydrochloric acid and one or two mixtures of methanol, ethanol, n-propanol, and isopropanol to absorption bottles d, e, and f to keep the mass fraction at 0...

Embodiment 2

[0018] Measure 200Kg of low-concentration complex ruthenium-containing waste liquid and add it to a 500L porcelain jar (the ruthenium content is 7.79‰ after analysis), slowly add 22Kg of hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid or two mixed acids under stirring, and then add A precipitant in 4674g ammonium sulfide, hydrazine hydrate, thiourea, sodium borohydride, sodium hydroxide, heated to boiling 1h to stop heating, diluted with water to 400L, unloaded, routinely filtered, washed, dried to obtain 1797g ruthenium slag ( After analyzing the ruthenium content 86.32%), the yield of ruthenium in the waste liquid is 98.62%.

[0019] Get 300g ruthenium slag drop in reactor a, and add 1.8L mass fraction and be 30% NaOH solution, add 2L deionized water in b and c, add to RuO 4 Add 2.5L of 4mol / L hydrochloric acid and one or two mixtures of methanol, ethanol, n-propanol, and isopropanol to absorption bottles d, e, and f to keep the mass fraction at 0.5%, and add ...

Embodiment 3

[0021] Measure 150Kg of low-concentration complex ruthenium-containing waste liquid and add it to a 500L porcelain jar (the ruthenium content is 1.06% after analysis), slowly add 18Kg of hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid or two mixed acids under stirring, and then add A precipitating agent in 3975g ammonium sulfide, hydrazine hydrate, thiourea, sodium borohydride, sodium hydroxide, heated to boiling 1h to stop heating, diluted with water to 300L, unloaded, routinely filtered, washed, dried to obtain 1783g ruthenium slag ( After analyzing the ruthenium content 88.39%), the yield of ruthenium in the waste liquid is 99.12%.

[0022] Get 300g ruthenium slag drop in reactor a, and add 2L mass fraction and be 25% NaOH solution, add 2.5L deionized water to b, add to RuO 4 Add 2.5L of 4mol / L hydrochloric acid and one or two mixtures of methanol, ethanol, n-propanol, and isopropanol to absorption bottles c, d, e, and f to keep the mass fraction at 0.5%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com