Adsorption film for synchronously fixing various oxygen-containing negative ions and preparation method thereof

An adsorption film and anion technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low resolution, low adsorption capacity of adsorption film, short shelf life, etc., and achieve easy control of the preparation process, excellent adsorption performance, The effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

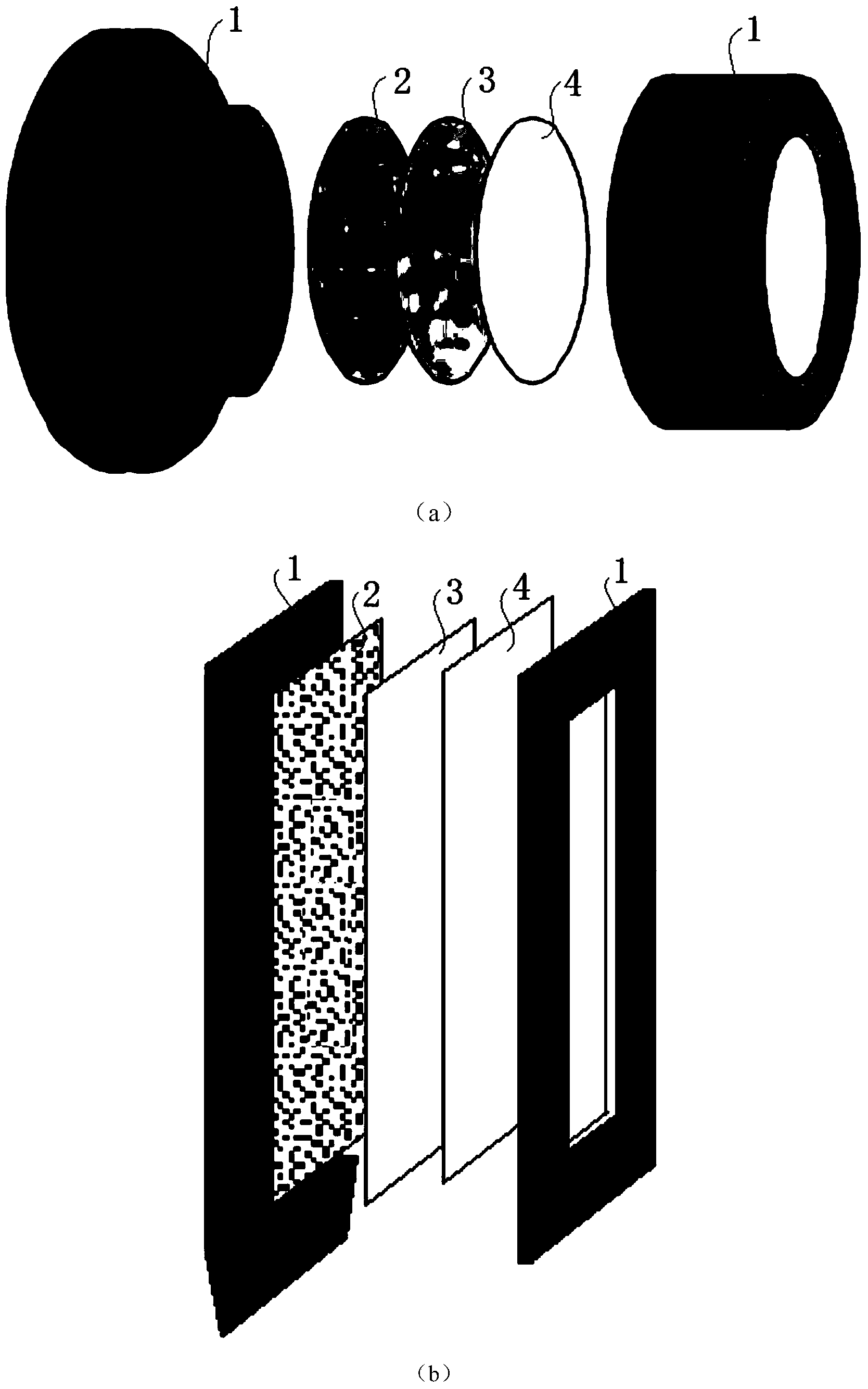

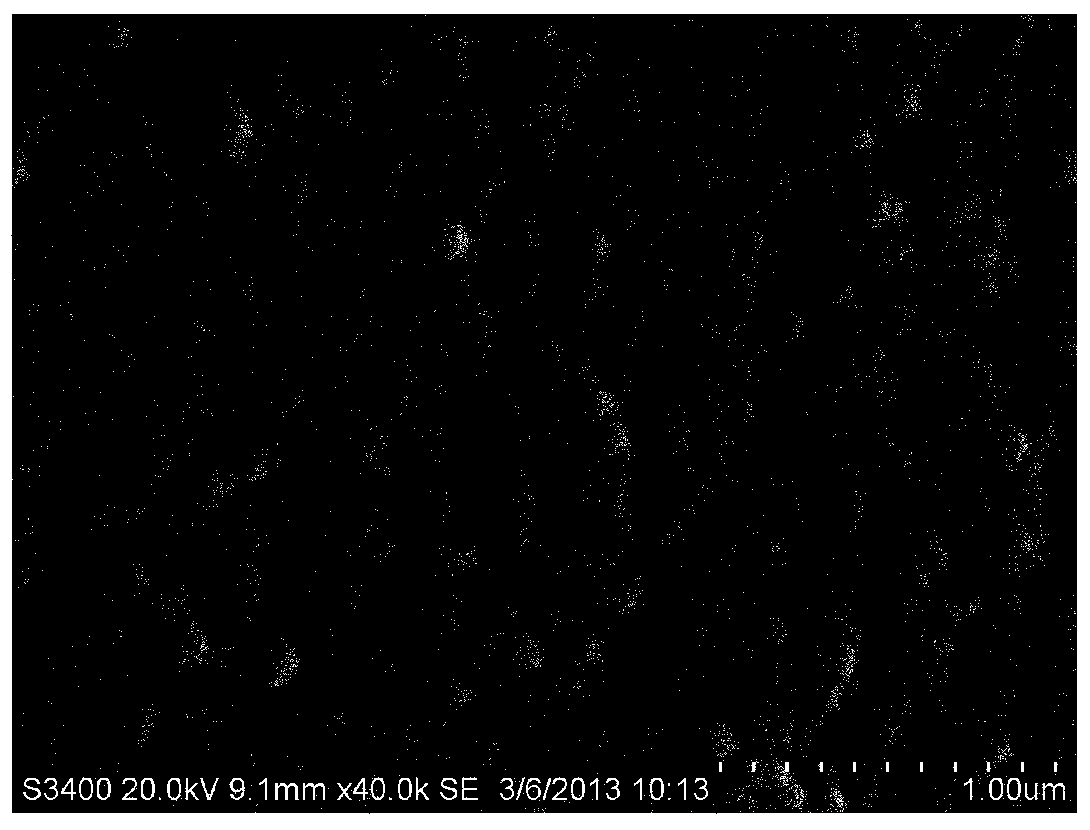

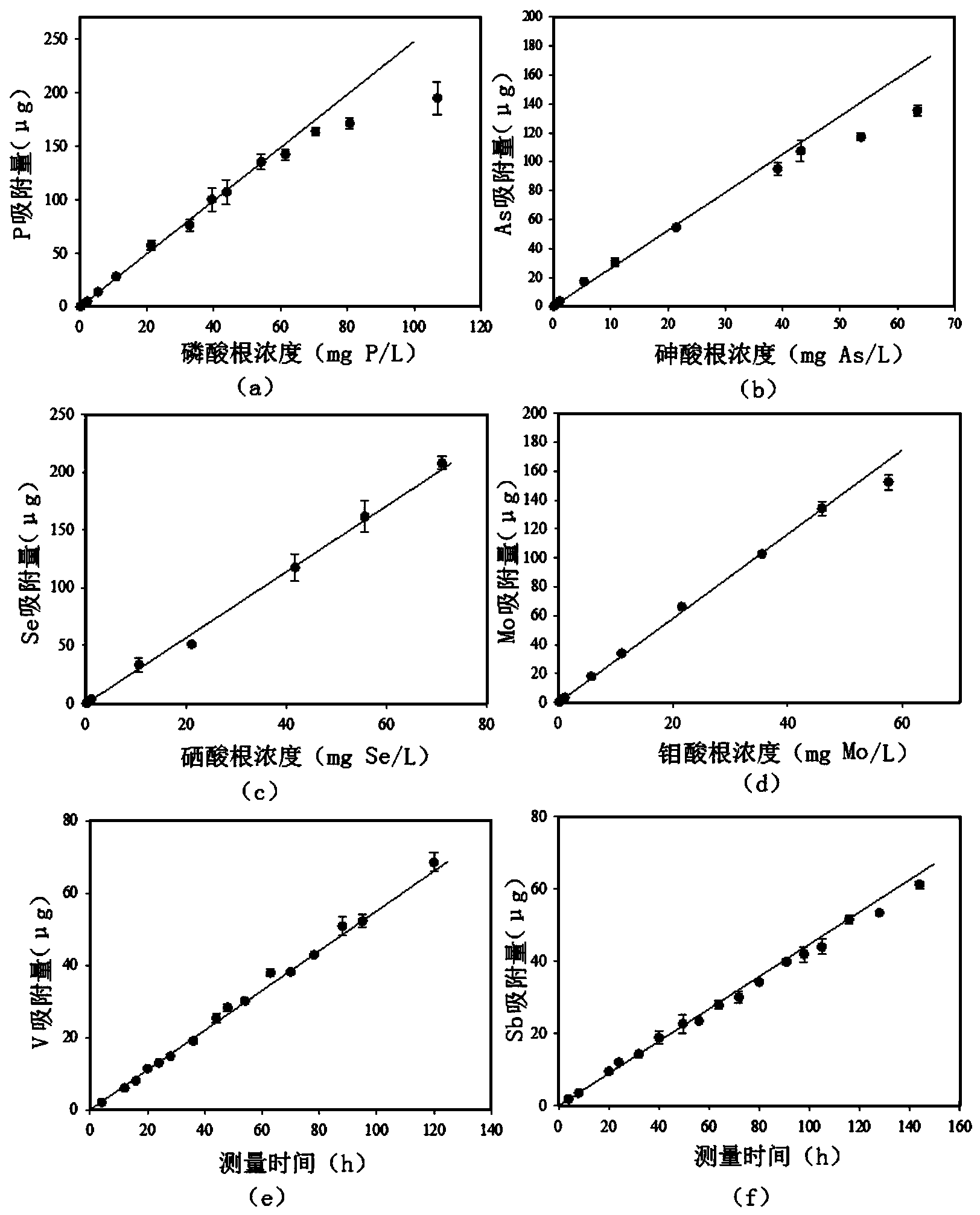

[0038] In conjunction with the accompanying drawings, a kind of adsorption membrane (such as figure 2 shown), the adsorption film is a polyacrylamide hydrogel film with zirconium dioxide particles evenly distributed on the surface, and the particle size of the zirconium dioxide particles is ≤0.3 μm. The oxygen-containing anions that can be adsorbed by the adsorption film of this embodiment include acid and sub-acid ions of elements such as phosphorus, vanadium, chromium, arsenic, selenium, molybdenum, antimony, tellurium, tungsten, bismuth, polonium and uranium, and are suitable for water bodies, Adsorption and analysis of various oxyanions in environmental media such as soil and sediment.

[0039] After theoretical analysis and repeated tests, the inventors concluded that if one wants to obtain an adsorption film with high adsorption capacity, long shelf life and high resolution for oxygen-containing anions including phosphorus, it is not only necessary to select a new adsor...

Embodiment 2

[0060] An adsorption film for synchronously immobilizing various oxygen-containing anions and its preparation method in this embodiment are basically the same as in Example 1, the difference is that in this embodiment, in the process of preparing the adsorption film for synchronously immobilizing various oxygen-containing anions :

[0061] In step 1, the cross-linking agent DGT gel cross-linker purchased from the British DGT Research Co., Ltd., the pure water prepared by the Milli-Q pure water machine and the propylene produced by GE Healthcare with a concentration of 40% by mass The amide solution was mixed according to the volume ratio of 1:3.0:2.3 to prepare the gel-making solution. The tetramethyldiethylamine solution whose volume is 1 / 200 of the gel-making solution and the ammonium persulfate solution whose volume is also 1 / 200 of the volume of the gel-making solution are added respectively in the above-mentioned gel-making solution to obtain a mixture solution. The pre...

Embodiment 3

[0068] An adsorption film for synchronously immobilizing various oxygen-containing anions and its preparation method in this embodiment are basically the same as in Example 1, the difference is that in this embodiment, in the process of preparing the adsorption film for synchronously immobilizing various oxygen-containing anions :

[0069] In step 1, the cross-linking agent DGT gel cross-linker purchased from the British DGT Research Co., Ltd., the pure water prepared by the Milli-Q pure water machine and the propylene produced by GE Healthcare with a concentration of 40% by mass The amide solution was mixed according to a volume ratio of 1:3.5:2.8 to prepare a gel-making solution. A tetramethyldiethylamine solution with a volume of 1 / 100 of the gel-making solution and an ammonium persulfate solution with a volume of 1 / 300 of the gel-making solution were added to the above-mentioned gel-making solution to prepare a mixed solution . The prepared mixed solution was then inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com