Middle and low voltage zinc oxide varistor and preparation method thereof

A varistor and zinc oxide technology, which is applied in the field of medium and low voltage zinc oxide varistors and its preparation, can solve the problems of large dispersion of varistor voltage, decline in chip quality, and low nonlinear coefficient, and achieve discrete varistor voltage The effect of small degree, strong ability to withstand combined waves, and high nonlinear coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

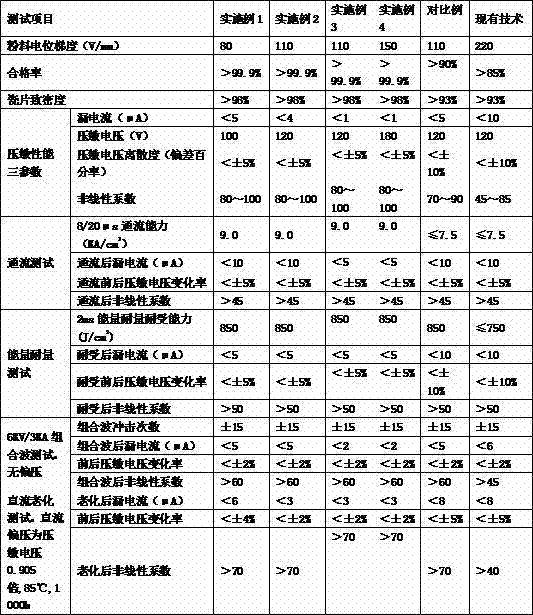

Examples

Embodiment 1

[0021] 1. Weigh and analyze 150 grams of ZnO and 4.0159 grams of Bi respectively 2 o 3 , 1.8847 g Co 3 o 4 , 4.4666 g Sb 2 o 3 , 1.1008 g MnCO 3 , 1.1087 g Ni 2 o 3 , 0.0708 g ZrO 2 , 0.0921 g SiO 2 , 0.1444 g SnO 2 , 0.0772 grams of MgO, 1.5293 grams of TiO 2 , 0.0178 g H 3 BO 3 , 0.0288 g Al(NO 3 ) 3 9H 2 O, 0.0326 g AgNO 3, 0.0097 g KNO 3 Then add 500 grams of zirconium balls, 250 grams of deionized water and 1.7 grams of dispersing agent, wet ball mill and mix for 4 hours, take it out, and quickly dry it in an oven at 120 ° C until it is completely dried to obtain medium and low pressure pressure sensitive Resistance mixed powder.

[0022] 2. Grind the mixed powder dried in step 1 with a mortar, add 35 grams of polyvinyl alcohol aqueous solution with a mass concentration of 5%, granulate, and then bake in an oven at 80°C to obtain a moisture content of 0.35%~ 0.55% granulation powder;

[0023] 3. Crush the granulated powder in step 2, completely pass...

Embodiment 2

[0028] 1. Weigh and analyze 150 grams of ZnO and 5.344 grams of Bi respectively 2 o 3 , 1.8587 g Co 3 o 4 , 5.288 g Sb 2 o 3 , 1.3309 g MnCO 3 , 1.2766 g Ni 2 o 3 , 0.0942 g ZrO 2 , 0.1724 g SiO 2 , 0.374 g SnO 2 , 0.1542 grams of MgO, 1.5291 grams of TiO 2 , 0.0296 g H 3 BO 3 , 0.0431 g Al(NO 3 ) 3 9H 2 O, 0.0487 g AgNO 3 , 0.0232 g KNO 3 Then add 600 grams of zirconium balls, 250 grams of deionized water and 1.7 grams of dispersing agent, wet ball milling for 4 hours, take it out, and quickly dry it in an oven at 140 ° C until it is completely dried to obtain medium and low pressure pressure sensitive Resistance mixed powder.

[0029] 2. Grind the mixed powder dried in step 1 with a mortar, add 40 grams of polyvinyl alcohol aqueous solution with a mass concentration of 5%, granulate, and then bake in an oven at 100°C to obtain a moisture content of 0.35%~ 0.55% granulation powder;

[0030] 3. Crush the granulated powder in step 2, completely pass throu...

Embodiment 3

[0035] 1. Weigh and analyze 150 grams of ZnO and 4.9324 grams of Bi respectively 2 o 3 , 1.8537 g Co 3 o 4 , 5.274 g Sb 2 o 3 , 1.2831 g MnCO 3 , 1.3897 g Ni 2 o 3 , 0.0711 g ZrO 2 , 0.1156 g SiO 2 , 0.375 g SnO 2 , 0.1163 grams of MgO, 1.3834 grams of TiO 2 , 0.0296 g H 3 BO 3 , 0.0375 g Al(NO 3 ) 3 9H 2 O, 0.0327 g AgNO 3 , 0.0156 g KNO 3 Then add 600 grams of zirconium balls, 250 grams of deionized water and 1.7 grams of dispersant, wet ball mill and mix for 4 hours, take it out, and quickly dry it in an oven at 130 ° C until it is completely dried to obtain medium and low pressure pressure sensitive Resistance mixed powder.

[0036] 2. Grind the mixed powder dried in step 1 with a mortar, add 40 grams of polyvinyl alcohol aqueous solution with a mass concentration of 5%, granulate, and then bake in an oven at 100°C to obtain a moisture content of 0.35%~ 0.55% granulation powder;

[0037] 3. Crush the granulated powder in step 2, completely pass throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com