Fireproof coating and preparation method thereof

A technology of fire retardant coating and acrylic emulsion, applied in the field of coatings, can solve the problems of poor water resistance, long drying time, short fire resistance time, etc., and achieve the effect of excellent water resistance, good decorative performance and long fire resistance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

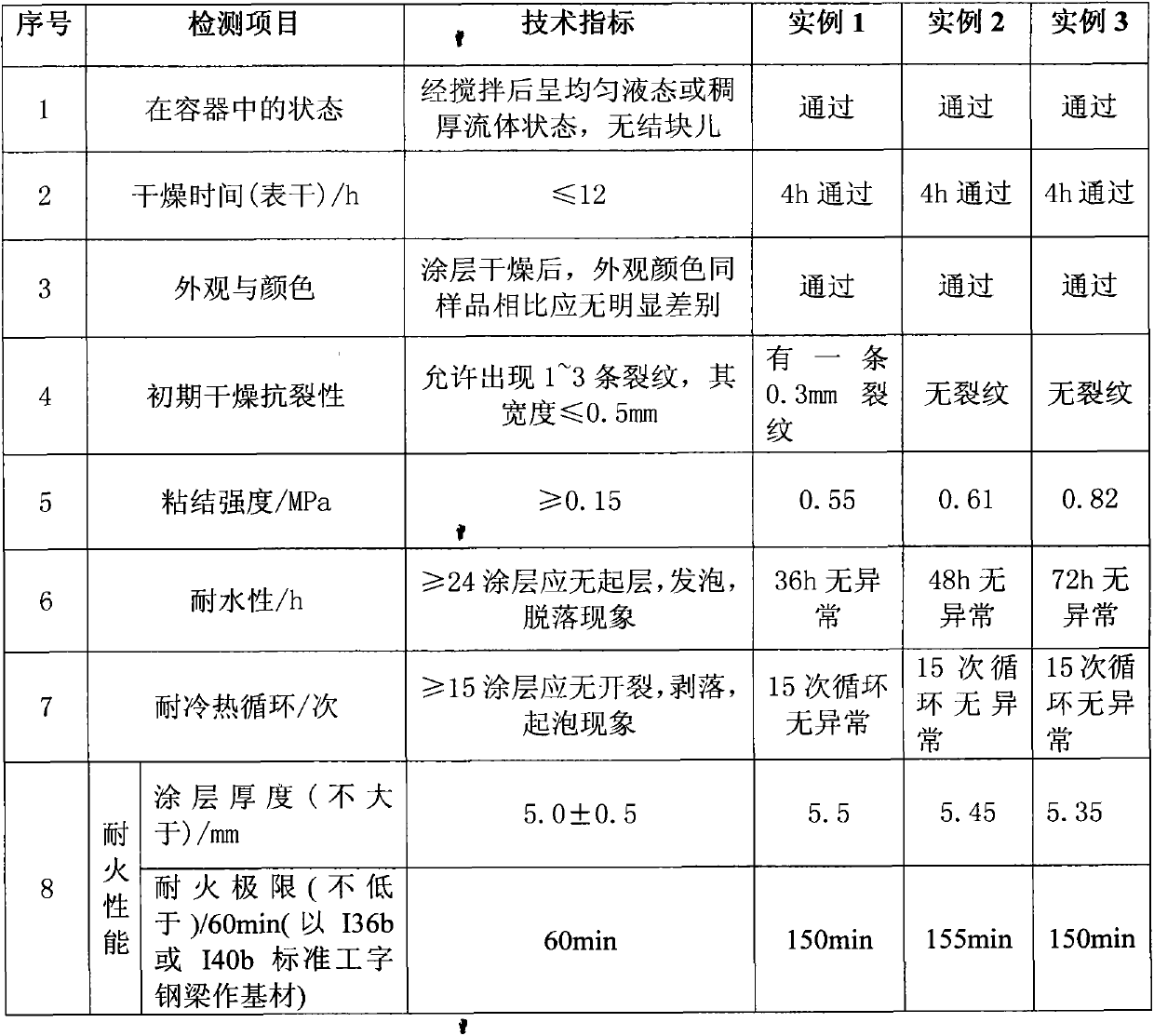

Examples

Embodiment 1

[0026] A kind of fireproof coating (water-based indoor thin steel structure fireproof coating) provided in the present embodiment 1, according to the proportioning by weight, the component of described fireproof coating comprises:

[0027] 225.5 parts of water, 1 part of hydroxyethyl cellulose (thickener), 5 parts of dispersant, 2.5 parts of defoamer, 6 parts of film-forming aid, acrylic emulsion (silicon acrylic emulsion: chlorine partial emulsion = 3: 2, Weight ratio) 200 parts, potassium silicate 30 parts, flame retardant (ammonium polyphosphate: pentaerythritol: melamine=5:2:3, weight ratio) 400 parts, chlorinated paraffin 70# 50 parts, antimony trioxide 25 parts , 10 parts of nano-magnesium hydroxide, 20 parts of composite zinc phosphate, 10 parts of titanium dioxide, 10 parts of mica powder, 1 part of anti-mold and anti-algae agent, 2 parts of leveling agent, 3 parts of alkali swelling thickener.

[0028] Among them, both hydroxyethyl cellulose and alkali-swellable thick...

Embodiment 2

[0047]A kind of fireproof coating (water-based indoor thin steel structure fireproof coating) provided in the present embodiment 2, according to the proportioning by weight, the component of described fireproof coating comprises:

[0048] 180 parts of deionized water, 1 part of hydroxyethyl cellulose (thickener), 5 parts of dispersant, 2 parts of defoamer, 8 parts of film-forming aid, acrylic emulsion (silicon acrylic emulsion: chlorine partial emulsion = 3: 2, weight ratio) 230 parts, potassium silicate 40 parts, flame retardant (ammonium polyphosphate: pentaerythritol: melamine=5:2:3, weight ratio) 420 parts, chlorinated paraffin 70#50 parts, antimony trioxide 20 parts, 5 parts of nano-magnesium hydroxide, 15 parts of composite zinc phosphate, 10 parts of titanium dioxide, 10 parts of mica powder, 1 part of anti-mold and anti-algae agent, 1 part of leveling agent, 3 parts of alkali swelling thickener.

[0049] Among them, both hydroxyethyl cellulose and alkali-swellable thic...

Embodiment 3

[0068] A kind of fireproof coating (water-based indoor thin steel structure fireproof coating) provided in the present embodiment 3, according to the proportioning by weight, the component of described fireproof coating comprises:

[0069] 120 parts of deionized water, 1 part of hydroxyethyl cellulose (thickener), 6 parts of dispersant, 2 parts of defoamer, 8 parts of film-forming aid, emulsion (silicon acrylic emulsion: chlorine partial emulsion=3:2 Weight ratio) 250 parts, potassium silicate 50 parts, flame retardant (ammonium polyphosphate: pentaerythritol: melamine=5:2:3, weight ratio) 450 parts, chlorinated paraffin 70#55 parts, antimony trioxide 20 parts , 5 parts of nano-magnesium hydroxide, 10 parts of composite zinc phosphate, 10 parts of titanium dioxide, 10 parts of mica powder, 1 part of anti-mold and anti-algae agent, 1 part of leveling agent, 2 parts of alkali swelling thickener.

[0070] Among them, both hydroxyethyl cellulose and alkali-swellable thickener are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com