Environment-friendly anticorrosive yellowing-resistant amino resin paint

An amino resin, anti-yellowing technology, applied in the field of paint, can solve the problems of heavy odor, easy to fall off, easy to corrode, etc., and achieve the effect of long service life, not easy to fall off, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

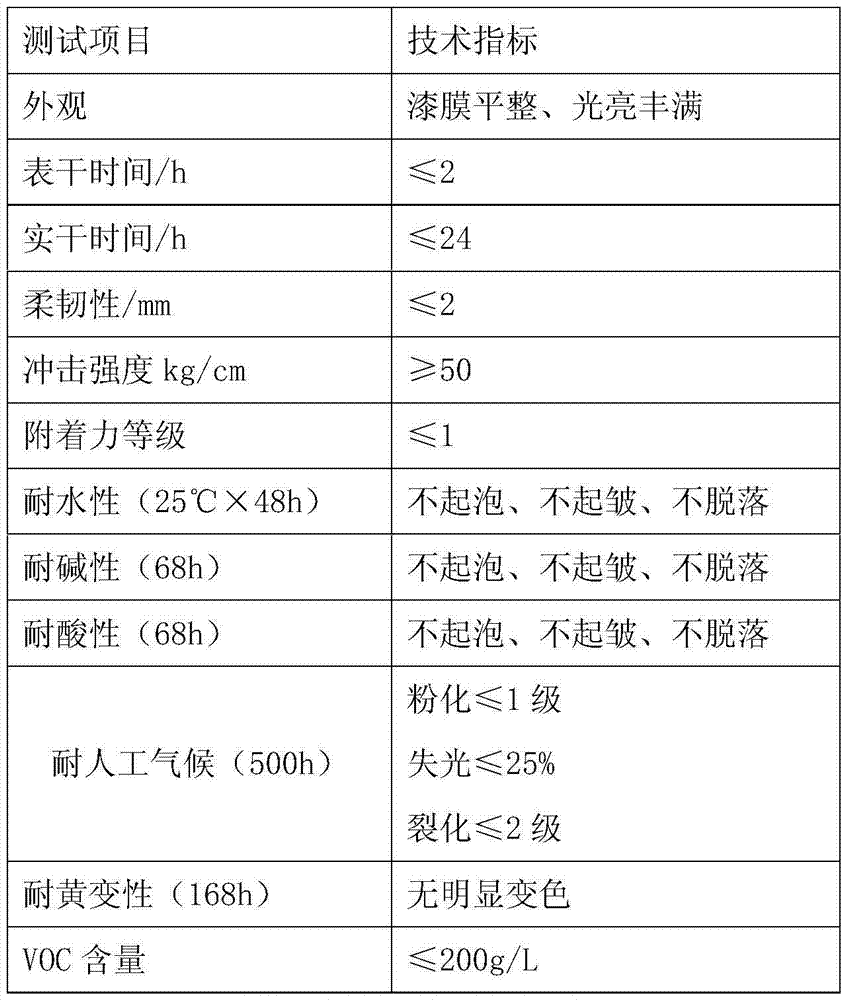

Image

Examples

Embodiment

[0012] The paint of this embodiment is made of the following raw materials in parts by weight: amino resin 32, phenolic resin 12, aluminum tripolyphosphate 4, zinc phosphate 2, zinc oxide 3, sodium dehydroacetate 3, rutile titanium dioxide 5, isopropanol 5 , Ethoxylated trimethylolpropane triacrylate 6, tetrabutylphosphine chloride 2, naphthenic dicarboxylic acid monoester 5, styrene 3, N-cyclohexylthiophthalimide 5, titanium Ester coupling agent TMC-TTS3, glycidyl acrylate 6, auxiliary agent 6, xylene 12, butyl acetate 12.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: loess 2, polytetrafluoroethylene powder 5, accelerator DM2, silane coupling agent KH5504, sodium laurate 2, jade 2, salicylic acid 3, phthalate Formate 40, propyl gallate 4, coix seed oil 3, vanadium diboride 2, epicatechin 3; the preparation method is to put loess and jade into a calciner for 3 hours at 720-740°C, and then Take it out, soak in 15% hydrochloric acid sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com