Corrosion-inhibiting anion-intercalated hydrotalcite film prepared by hydrothermal deposition on magnesium alloy surface

A technology of anion intercalation and hydrotalcite, which is applied in metal material coating technology, coating, liquid chemical plating, etc., can solve problems such as environmental pollution, water and soil pollution, poisonous electroplating method, etc., and achieve green preparation process Environmental protection, high corrosion resistance, and effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention, a kind of preparation method of corrosion-inhibiting anion intercalation hydrotalcite film, it comprises the following steps:

[0033] Step 1. Pretreatment of magnesium alloy samples:

[0034] First, the magnesium alloy sheet is polished with sandpaper until the surface becomes a mirror surface, degreased in lye, rinsed with deionized water, cleaned with an ultrasonic cleaner in acetone for 10 minutes, then ultrasonically cleaned in deionized water for 10 minutes, and cooled with air. Blow dry and set aside.

[0035] Step 2, preparation of LDHs sol:

[0036] (1) The soluble divalent metal salt AY 2 and soluble trivalent metal salt BY 3 Dissolve in deionized water according to the ratio of substance quantity 2:1, and make AY of 0.02~0.2mol / L 2 and 0.01~0.1mol / LBY 3 The mixed solution, the mixed solution is placed in a three-necked flask, stirred, heated to 60 ~ 80 ° C;

[0037] (2) Weigh a certain amount of NaOH and corrosion-inhibiting anion...

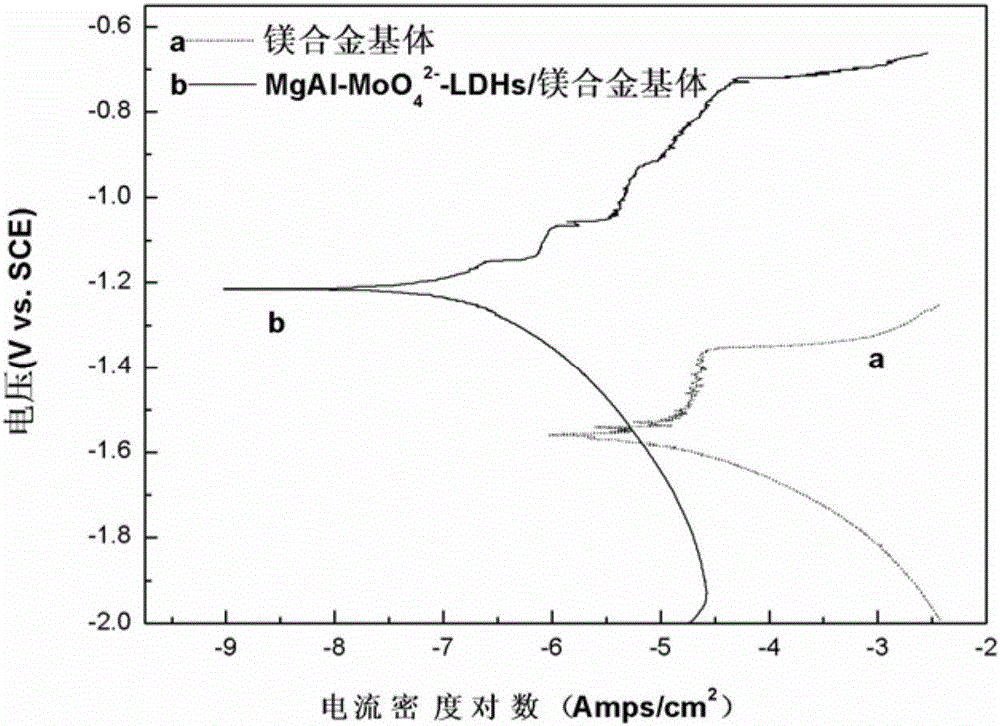

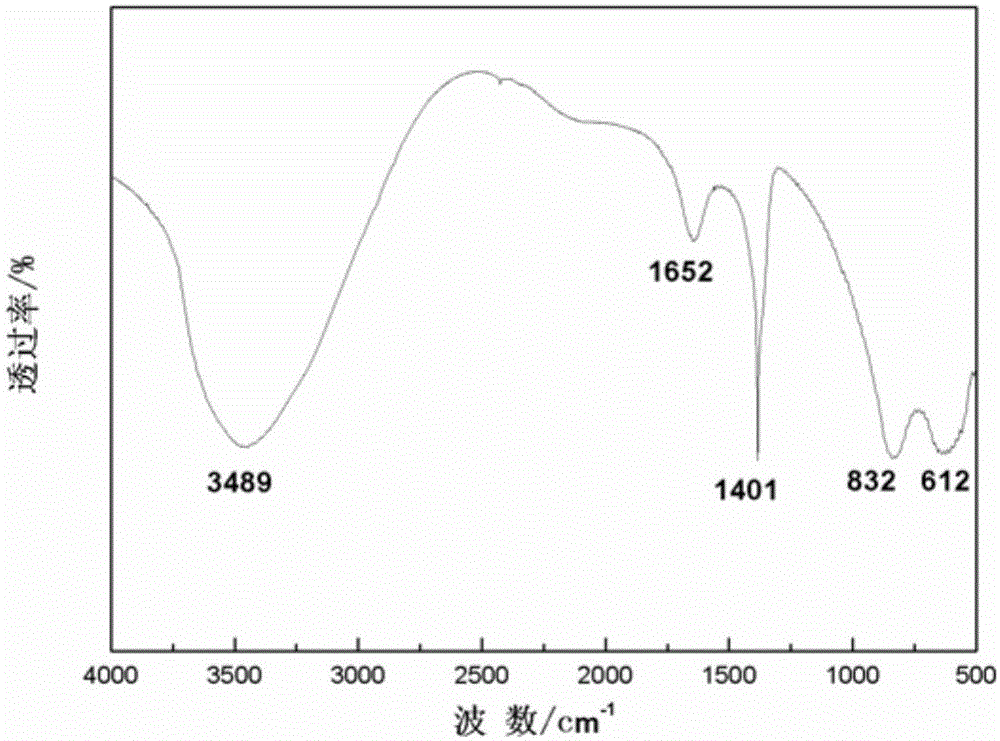

Embodiment 1

[0042] Step 1, pretreatment of magnesium alloy samples:

[0043] First, the die-casting magnesium alloy AZ31 sample with a size of 20mm×20mm×3mm is polished with sandpaper until the surface is mirror-like, degreased in lye, rinsed with deionized water, cleaned with an ultrasonic cleaner in acetone for 10 minutes, and then placed Ultrasonic cleaning in deionized water for 10 minutes, air-dried with cold air, and set aside.

[0044] Step 2. Magnesium aluminum molybdate LDHs (MgAl-MoO 4 2- -LDHs) sol preparation:

[0045] (1) Weigh 0.04molMg(NO 3 ) 2 ·6H 2 O and 0.02molAl(NO 3 ) 3 9H 2 O, add 150mL deionized water as a solvent to make a solution, put it in a three-necked flask, stir and heat to 80°C;

[0046] (2) Weigh 0.13molNaOH and 0.04molNa 2 MoO 4 2H 2 Dissolve O in 150mL deionized water, mix well, and 2 Slowly add it into a three-necked flask under protection, adjust the pH to 10, keep heating at 80°C, and keep stirring with a stirrer for 72h, and age for 12h. ...

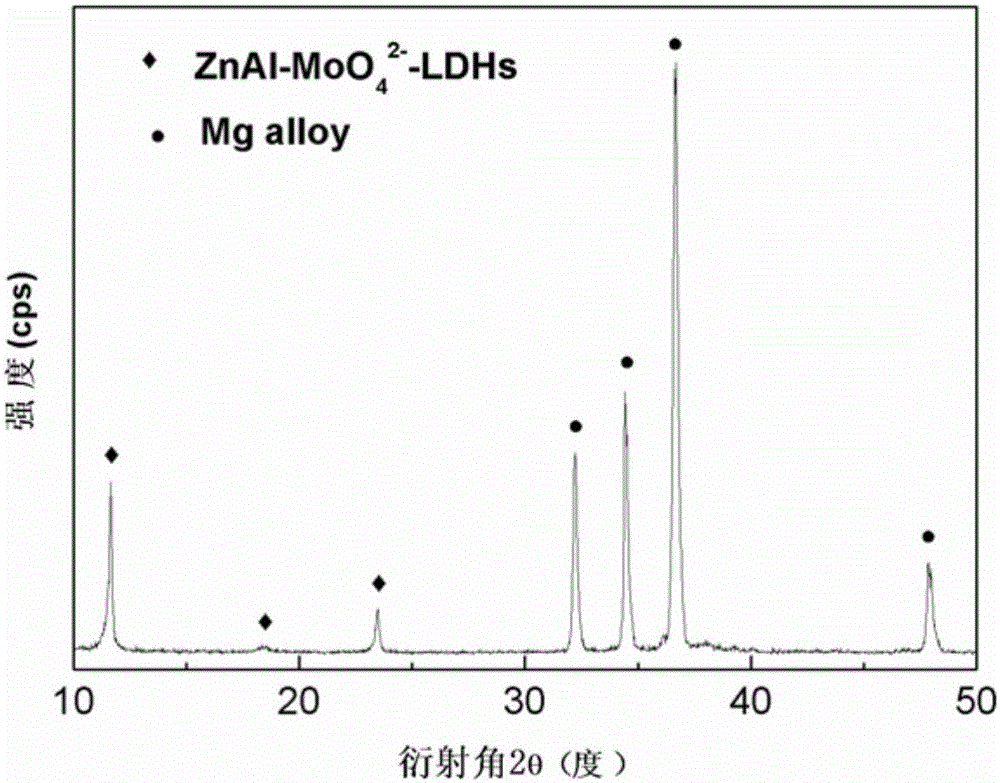

Embodiment 2

[0052] Step 1 is the same as Embodiment 1 Step 1, and the difference from Embodiment 1 is:

[0053] Step 2. Magnesium aluminum tungstate LDHs (MgAl-WoO 4 2- -LDHs) sol preparation:

[0054] (1) Weigh 0.04mol of Mg(NO 3 ) 2 ·6H 2 O and 0.02mol of Al(NO 3 ) 3 9H 2 O, add 150mL deionized water as a solvent to make a solution, put it in a three-necked flask, stir and heat to 70°C;

[0055] (2) Weigh 0.13molNaOH and 0.04molNa 2 WoO 4 2H 2 Dissolve O in 150mL deionized water, mix well, and 2 Slowly add it into a three-necked flask under protection, adjust the pH to 9, keep heating at 70°C, keep stirring with a stirrer for 72h, and age for 12h.

[0056] Step 3, steps of magnesium alloy sample and above-mentioned LDHs sol hydrothermal deposition:

[0057] Put the treated magnesium alloy sample and the above 70mLLDHs sol in a 100mL hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a drying oven for hydrothermal deposition, set the temperature at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com