Preparation method of tiopronin tablets

A technology of tiopronin tablets and tiopronin, which is applied in the direction of pill delivery, digestive system, peptide/protein components, etc., can solve the problems of unsuitable tiopronin tablets, achieve good drug stability, prevent damp heat damage, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of tiopronin tablet, the method is made up of the following steps:

[0020] 1) Excipient granulation: Put pregelatinized starch, microcrystalline cellulose, lactose and crospovidone into the wet mixing granulator, add binder (PVP-K30 with a mass concentration of 5% aqueous solution), granulation;

[0021] 2) Dry the wet granules prepared in step 1) at 70°C, collect the granules when the moisture content of the granules reaches 1-3%, and sizing the granules with a fast granulator;

[0022] 3) Add tiopronin raw material and additional auxiliary materials (silicon dioxide, talc and magnesium stearate), and mix;

[0023] 4) Determining the content of tiopronin in the mixed granules; compressing the mixed granules with qualified content into tablets to make tiopronin plain tablets.

[0024] 5) Coating the prepared tiopronin tablets to make tiopronin sugar-coated tablets.

[0025] Take the prepared tiopronin tablet sample, place it in a stability test ...

Embodiment 2

[0030] A preparation method of tiopronin tablet, the method is made up of the following steps:

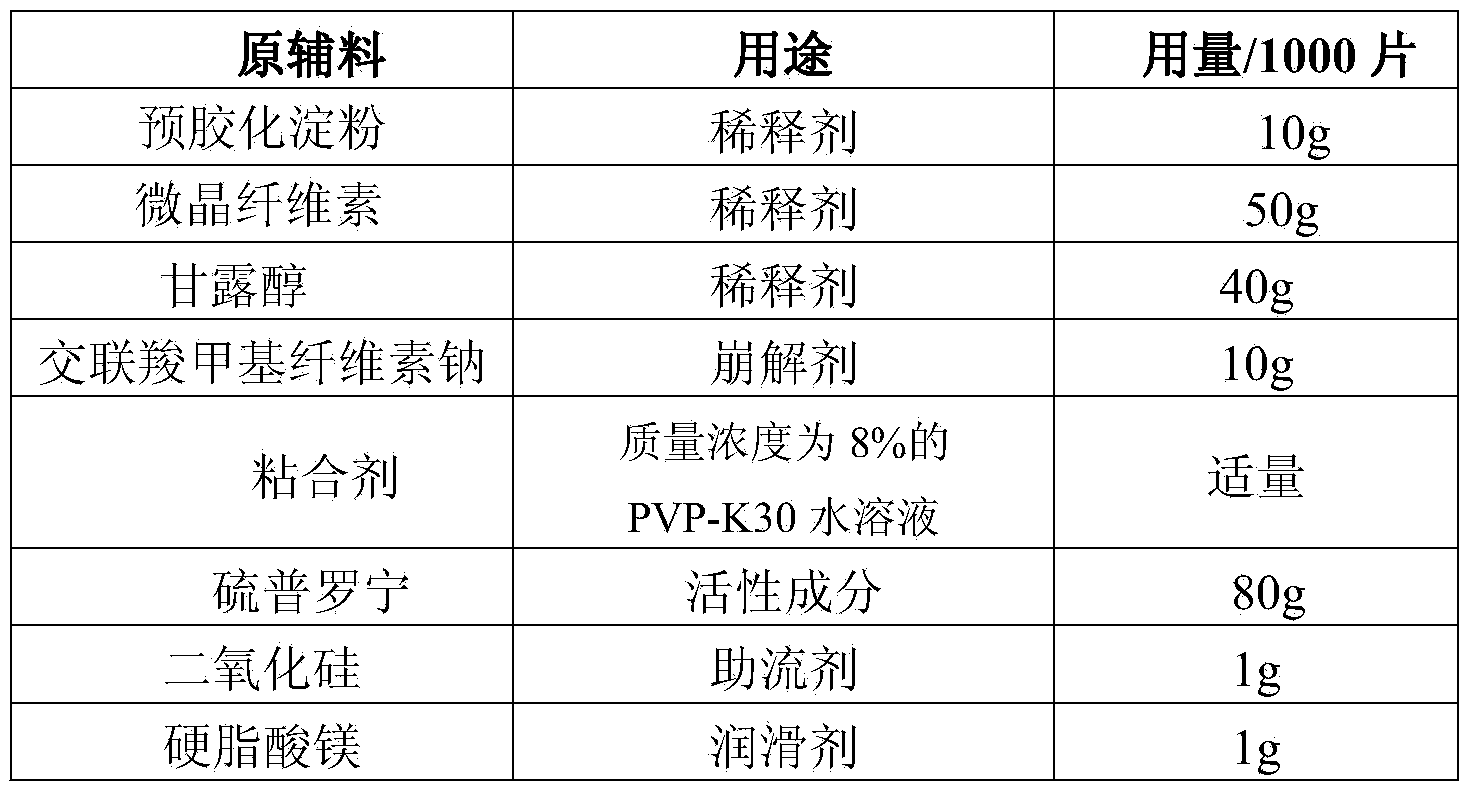

[0031] 1) Excipient granulation: Put pregelatinized starch, microcrystalline cellulose, mannitol and croscarmellose sodium into the wet mixing granulator, add binder (mass concentration of 8% PVP-K30 aqueous solution), granulation;

[0032] 2) Dry the wet granules prepared in step 1) at 60°C, collect the granules when the moisture content of the granules reaches 1-3%, and sizing the granules with a fast granulator;

[0033] 3) Add tiopronin raw material and additional excipients (silicon dioxide and magnesium stearate), and mix;

[0034] 4) Determining the content of tiopronin in the mixed granules; compressing the mixed granules with qualified content into tablets to make tiopronin plain tablets;

[0035] 5) Coating the prepared tiopronin tablets with enteric coating powder solution to make tiopronin enteric-coated tablets.

[0036] Take the prepared tiopronin tablet sample, pl...

Embodiment 3

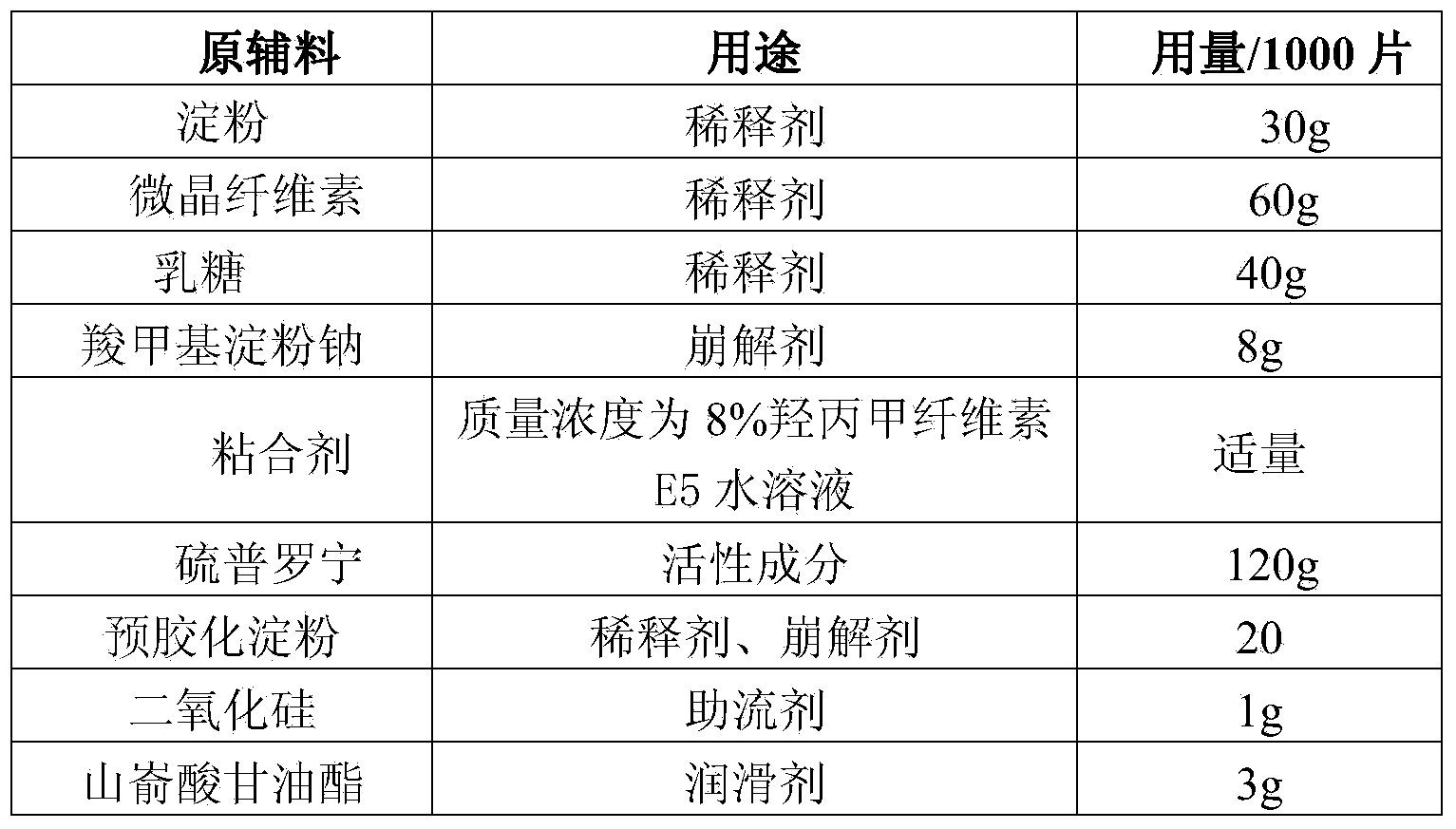

[0040] A preparation method of tiopronin tablet, the method is made up of the following steps:

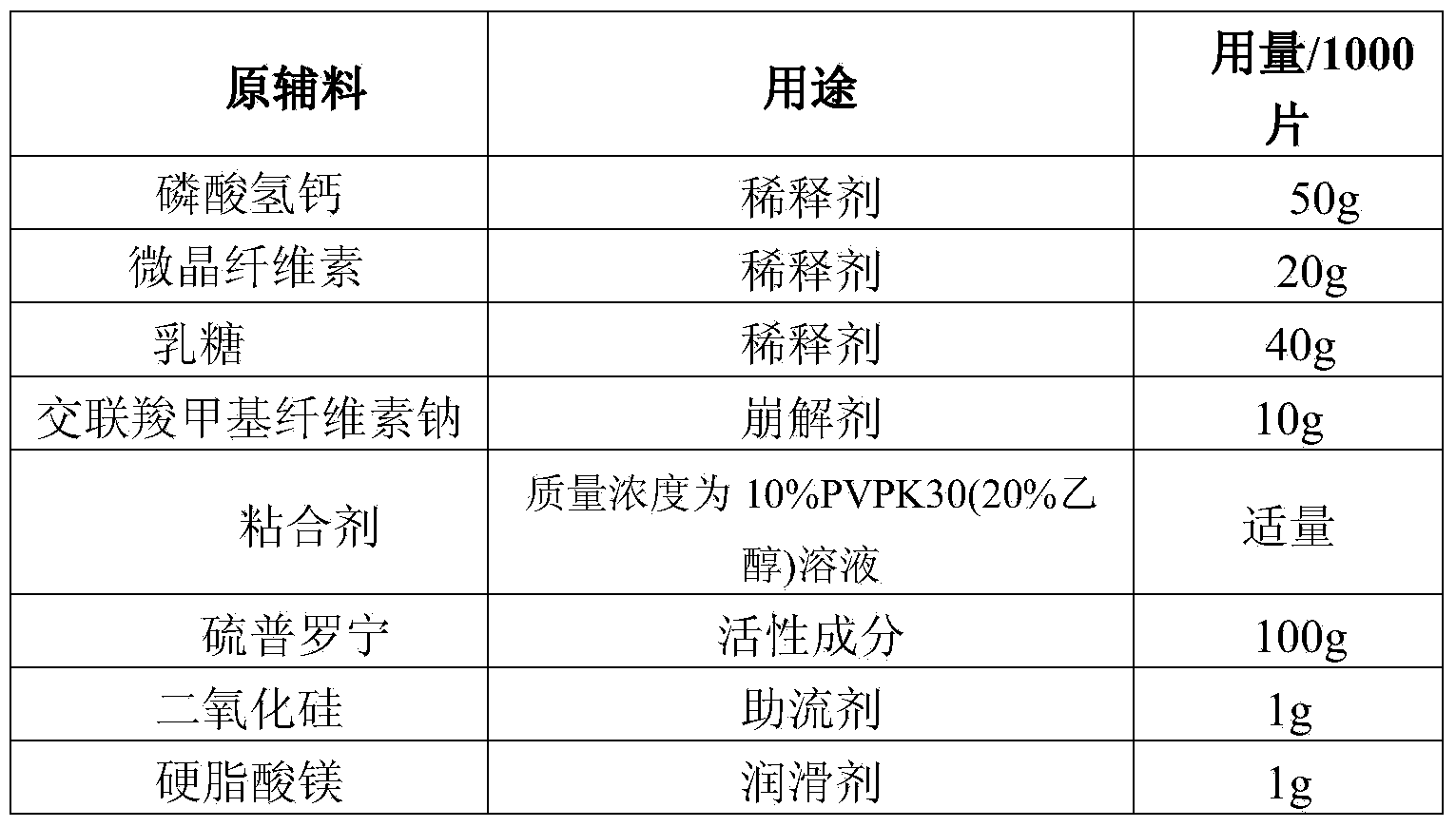

[0041] 1) Excipient granulation: Put calcium hydrogen phosphate, microcrystalline cellulose, lactose and croscarmellose sodium into the wet mixing granulator, add binder after mixing (mass concentration is 10%PVP- K30 (20% ethanol) solution), granulated;

[0042] 2) Dry the wet granules prepared in step 1) at 65°C, collect the granules when the moisture content of the granules reaches 1-3%, and sizing the granules with a fast granulator;

[0043] 3) Add tiopronin raw material and additional excipients (silicon dioxide and magnesium stearate), and mix;

[0044] 4) Determining the content of tiopronin in the mixed granules; compressing the mixed granules with qualified content into tablets to make tiopronin tablets (i.e. tiopronin plain tablets).

[0045] 5) Coating the prepared tiopronin tablets with enteric coating powder solution to make tiopronin enteric-coated tablets.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com