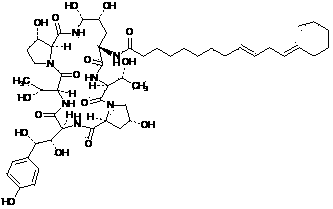

Separation purification method and use of echinocandin B

A technology of echinocandin and mycelium, which is applied in the field of separation of echinocandin B from fermentation broth, can solve the problems of inability to remove pigments well, the separation medium is expensive, and the quality of antibacterial drugs is affected, and the operation is achieved. Simple, mild separation conditions, easy to operate, suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

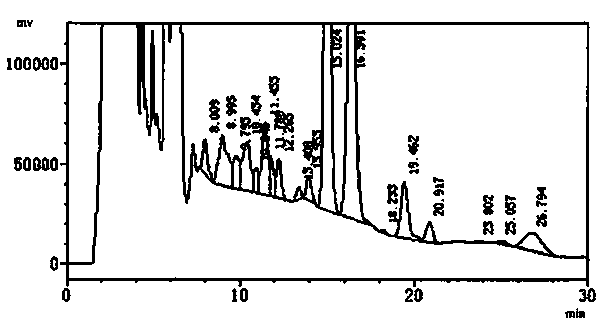

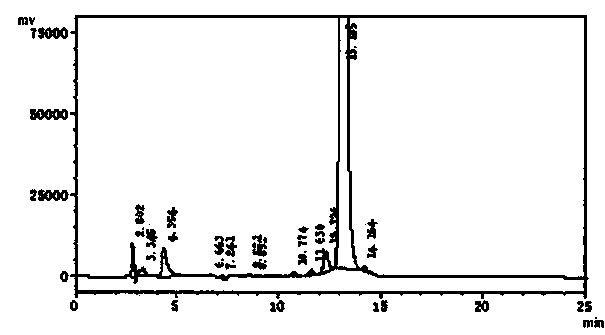

Image

Examples

Embodiment 1

[0058] Take 1000ml of echinocandin B fermentation broth, adjust the pH to 5.0 with oxalic acid, add 20g of perlite and stir for 2 hours, filter, wash mycelium with 500ml of water, and collect 352g of mycelium after drying.

[0059] Take 352g of mycelium, add 1000ml of ethanol solution, soak and stir for 6 hours, filter to obtain about 980ml of extract, concentrate the extract at 50°C to a volume of 100ml; filter the obtained mycelium after extraction Add it to 750ml ethanol solution, stir for 4 hours while soaking, filter to obtain about 730ml of extract, concentrate the extract at 50°C to a volume of 75ml, cool to room temperature, combine the two extracts at 25°C, vacuum Concentrate the extract at a temperature of -0.08 Mpa until the ethanol content in the solution is 25%.

[0060] Take 100ml of the extract, add 10ml of petroleum ether to shake, let it stand for 2 hours, collect 92ml of the organic layer solution, and concentrate to 9ml at 40°C.

[0061] Take 300 mL of ...

Embodiment 2

[0063] Take 1000ml of echinocandin B fermentation broth, adjust the pH to 4.0 with acetic acid, add 15g of talcum powder and stir for 2 hours, filter, wash mycelium with 500 ml of water, and collect 350g of mycelium after drying.

[0064] Take 350g of mycelium, add 1000ml of methanol solution, stir for 4 hours while soaking, filter to obtain about 970ml of extract, concentrate the extract at 50°C to a volume of 100ml; filter the obtained mycelium after leaching Add it to 750ml of methanol solution, stir for 3 hours while soaking, filter to obtain about 725ml of extract, concentrate the extract at 50°C to a volume of 72ml, cool to room temperature, and combine the two extracts. Concentrate the extract solution at 25°C with a vacuum of -0.08 Mpa until the methanol content in the solution is 20%.

[0065] Take 100ml of the extract, add 10ml of n-hexane to shake, let it stand for 2 hours, collect 90ml of the organic layer solution, and concentrate to 9ml at 40°C.

[0066] Take 3...

Embodiment 3

[0068] Take 1000ml of echinocandin B fermentation broth, adjust the pH to 6.0 with carbonic acid, add 35g of micropowdered silica gel and stir for 2 hours, filter, wash mycelium with 500 ml of water, and collect 355g of mycelium after drying.

[0069] Take 355g of mycelium, add 1000ml of acetone solution, soak and stir for 6 hours, filter to obtain about 985ml of extract, concentrate the extract at 50°C to a volume of 100ml; filter the obtained mycelium after extraction Add it to 750ml of acetone solution, stir for 3 hours while soaking, filter to obtain about 735ml of extract, concentrate the extract at 50°C to a volume of 75ml, cool to room temperature, and combine the two extracts. Concentrate the extract solution at 25°C with a vacuum of -0.08 Mpa until the acetone content in the solution is 28%.

[0070] Take 100ml of the extract, add 10ml of n-heptane to shake, let it stand for 2 hours, collect 90ml of the organic layer solution, and concentrate to 9ml at 35°C.

[0071]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com