Superparamagnetic nanospheres and preparation method thereof

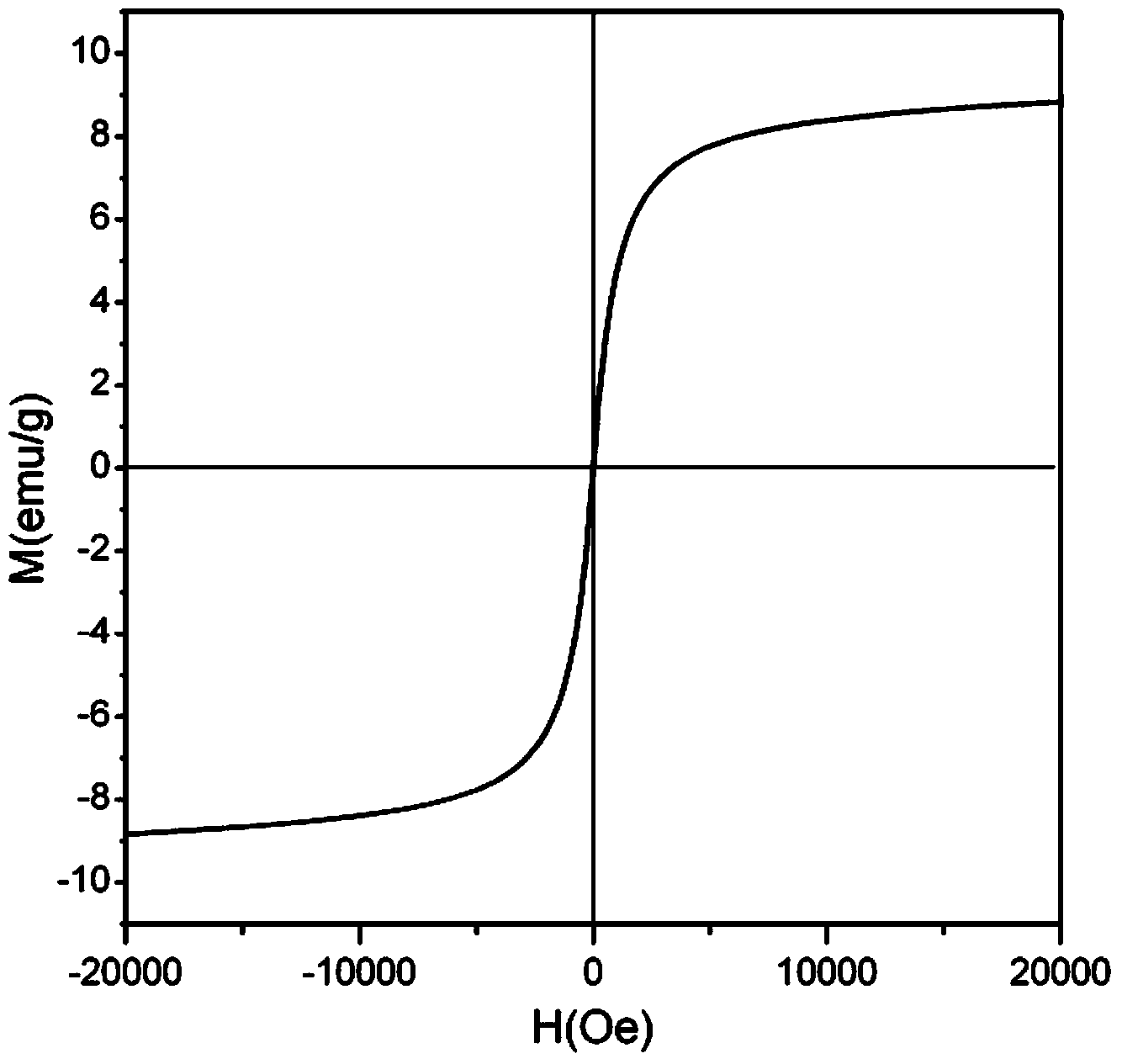

A superparamagnetic and nanosphere technology, applied in the field of nanomaterials, can solve the problems of low particle loading density, uneven particle distribution, and uneven particle size, and achieve the effects of improving stability, overcoming uneven distribution, and increasing loading density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

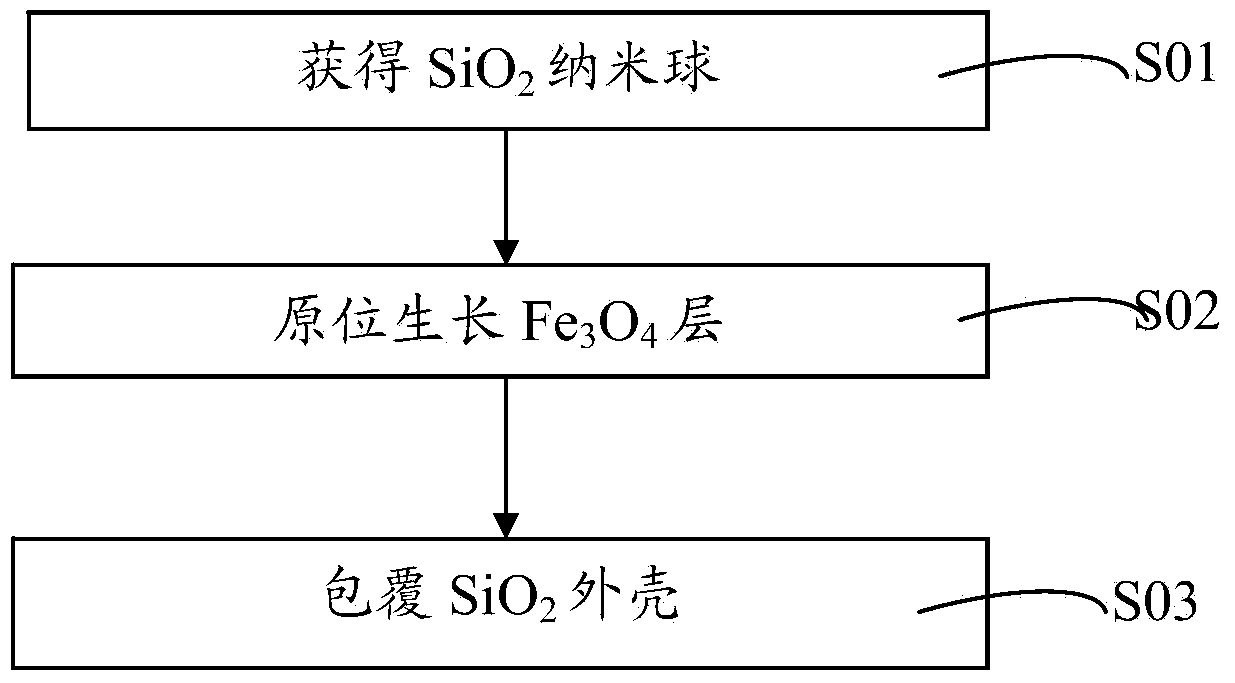

[0024] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned superparamagnetic nanospheres, the process flow of the preparation method is as follows figure 1 shown. The preparation method of the superparamagnetic nanosphere comprises the following steps:

[0025] S01. Obtain the above SiO 2 nanoparticles;

[0026] S02. On SiO 2 In situ growth of Fe on the outer surface of nanoparticles 3 o 4 Nanoparticles: the SiO in step S01 2 The nanoparticles are miscible with the polyol solution, then the organic iron compound is added, and heated to reflux to obtain the above SiO 2 In situ growth of nanoparticles as templates to form Fe 3 o 4 Shell SiO 2 Fe 3 o 4 nanospheres;

[0027] S03. In Fe 3 o 4 The outer surface of the layer is coated with SiO 2 Shell: SiO2 in step S02 2 Fe 3 o 4 The composite nanospheres are dispersed in a surfactant-solution, and tetraethyl orthosilicate is added under alkaline conditi...

Embodiment 1

[0042] A superparamagnetic nanosphere and a preparation method thereof. The preparation method of this superparamagnetic nanosphere is as follows

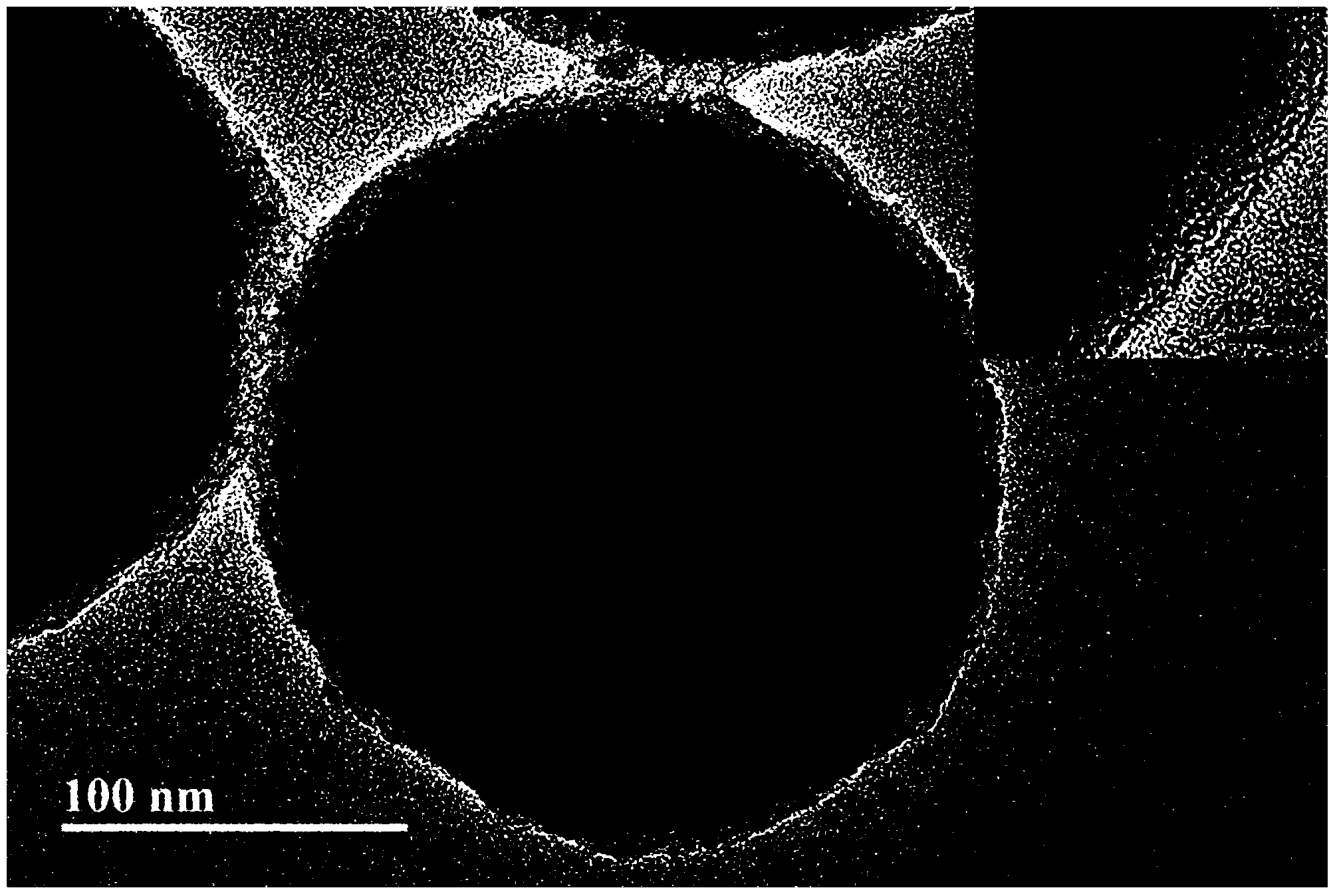

[0043] S11. Obtain SiO 2 Nanoparticles: Mix 75mL of cyclohexane, 18mL of n-hexanol and 17.7mL of Triton X-100, add 4.2mL of water and 600 μL of ammonia to form an inverse microemulsion; then add 1.5mL of TEOS, and the inverse microemulsion was stirred at room temperature for 48 h; then 70 mL of ethanol was added to break the emulsion, centrifuged at 6000 rpm for 5 min, and the precipitate was washed with isopropanol, ethanol and water in sequence to obtain SiO with a diameter of 82 nm. 2 ball;

[0044] S12. In situ growth of Fe 3 o 4 Nanoparticles: 75 mg of SiO obtained in step S11 2 Dissolve the ball in 500 μL of ethanol, add it into a two-necked round-bottomed flask containing 5ml triethylene glycol and 66mg iron acetylacetonate; drain the ethanol in the solution under vacuum, raise the temperature to 110°C and keep it for 2...

Embodiment 2

[0047] A superparamagnetic nanosphere and a preparation method thereof. The preparation method of this superparamagnetic nanosphere is as follows

[0048] S21. Obtain SiO 2 Nanoparticles: Mix 75mL of cyclohexane, 18mL of n-hexanol and 17.7mL of Triton X-100, add 4.2mL of water and 600 μL of ammonia to form an inverse microemulsion; then add 1.5mL of TEOS, and the inverse microemulsion was stirred at room temperature for 48 h; then 70 mL of ethanol was added to break the emulsion, centrifuged at 6000 rpm for 5 min, and the precipitate was washed with isopropanol, ethanol and water in sequence to obtain SiO with a diameter of 82 nm. 2 ball;

[0049] S22. In situ growth of Fe 3 o 4 Nanoparticles: 375 mg of SiO obtained in step S21 2 Dissolve the ball in 2.5ml of ethanol, add it into a two-necked round-bottomed flask containing 25ml of triethylene glycol and 330mg of iron acetylacetonate; drain the ethanol in the solution under vacuum, raise the temperature to 110°C and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com