A detection method for chemical bonding at the interface of tie paint/antifouling paint organic coating

A technology of organic coating and interface chemistry, which is applied in the detection field of chemical bonding at the interface of connecting paint/antifouling paint organic coating, which can solve the problems of difficult detection of chemical reactions, retention of bonding forms, and difficulty in finding the bonding interface, etc. Achieve the effect of simple detection method, prolong service life and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

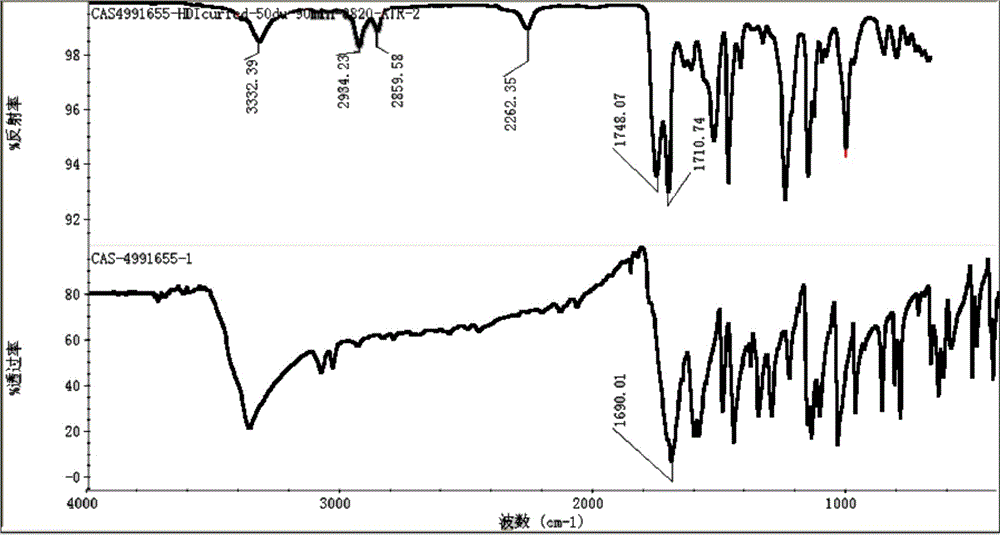

[0055] With 4.8% oxazole thiol ketone, 5.2% hexamethylene diisocyanate, 0.1% initiator and 89.9% solvent, a modified isocyanate polymer is prepared, and in the prepared modified isocyanate polymer, add Methyl butanone, preparation of the synthetic isocyanate prepolymer concentration of 10% solution, brushing on the surface of the connecting coating, still has -NCO active groups through infrared spectrum analysis; After the reaction, X-ray energy spectrum analysis and calculation can be obtained, the S / Si ratio on the interface unit area corresponds to the reaction mole ratio is 2.8×10 -6 mol / mm 2 .

Embodiment 2

[0057] Prepare a modified isocyanate polymer with 9.8% oxazole thiol ketone, 10.2% hexamethylene diisocyanate, 0.1% initiator and 79.9% solvent, and add methyl Butanone, the solution of the isocyanate prepolymer concentration synthesized by the preparation is 20%, brushed on the surface of the connecting coating, and still has -NCO active groups through infrared spectrum analysis; after reacting with the hydroxyl group on the surface of the connecting paint coating , by X-ray energy spectrum analysis and calculation, it can be obtained that the S / Si ratio on the interface unit area corresponds to the reaction mole ratio of 1.9×10 -6 mol / mm 2 .

Embodiment 3

[0059] With 14.6% benzothiol ketone, 15.4% hexamethylene diisocyanate, 0.1% initiator and 69.9% solvent, a modified isocyanate polymer is prepared, and methyl Butanone, the concentration of the prepared isocyanate prepolymer is 30% solution, brushed on the surface of the connecting coating, and still has -NCO active groups through infrared spectrum analysis; after reacting with the hydroxyl group on the surface of the connecting paint coating , by X-ray energy spectrum analysis and calculation, it can be obtained that the S / Si ratio on the interface unit area corresponds to the reaction mole ratio is 3.2×10 -6 mol / mm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com