Organic phosphorus electrochemical biosensor based on adsorption of nano particles

A biosensor and nanoparticle technology, which is applied in the field of analysis and detection, can solve the problems of expensive gold electrodes, achieve good regeneration, reduce construction costs, and have small non-specific adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

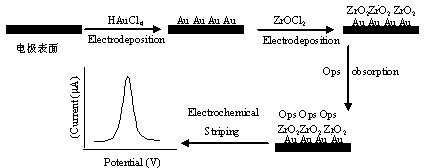

Method used

Image

Examples

Embodiment 1

[0030] The glassy carbon electrodes are sequentially used with 0.3 μm and 0.05 μm A1 2 o 3 The powder was polished to a mirror surface, and then ultrasonically cleaned in 95% ethanol and distilled water for 4 min, and then rinsed with secondary water and blown dry with nitrogen. Place the cleaned electrode in 4 mmol / L chloroauric acid solution, add 0.1 mol / L KNO 3 To support the electrolyte, CHI760b electrochemical workstation was used to electrodeposit nano-gold particles. The electrochemical reaction cell was a three-electrode system, the glassy carbon electrode was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum electrode was used as the counter electrode. Electrodeposited at 1.0 V for 150 s, a layer of gold nanoparticles was electrodeposited on the glassy carbon electrode.

[0031] Rinse the glassy carbon electrode on which gold nanoparticles have been deposited with 95% ethanol and water in sequence,...

Embodiment 2

[0043] Electrodeposit a layer of nano-gold particles on the surface of the glassy carbon electrode in the same way as in case 1, and then electrodeposit a layer of zirconia nanoparticles on the nano-gold particles to make ZrO 2 Organophosphorus electrochemical biosensor with particle layer / nano-gold / glassy carbon electrode structure.

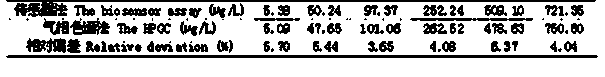

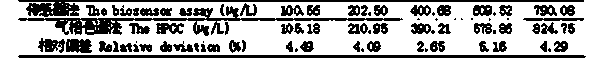

[0044] The above organophosphorus sensor can be directly used for the detection of paraoxon in water phase. The organophosphorus sensor was soaked in the paraoxon solution, stirred gently for 5 min for adsorption, and then the electrochemical detection of the stripping peak current was performed on a CHI760b electrochemical workstation. First take the paraoxon standard solution concentration of known concentration as the abscissa, and the corresponding square wave stripping voltammetry peak current as the ordinate to draw a graph to obtain the working curve of the sensor for paraoxon. The sensor SWV stripping peak current has a linear relations...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com