Nitrogen-doped graphene/metal composite current collector and preparation method thereof

A nitrogen-doped graphene and metal composite technology, applied in the direction of electrode carriers/current collectors, capacitor parts, etc., can solve the problems of mechanical strength gap of graphene films, insufficient uniformity of graphene films, and difficulty in obtaining graphene suspensions. , to achieve the effect of enhancing mechanical strength and electrical conductivity, easy large-scale industrial production, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

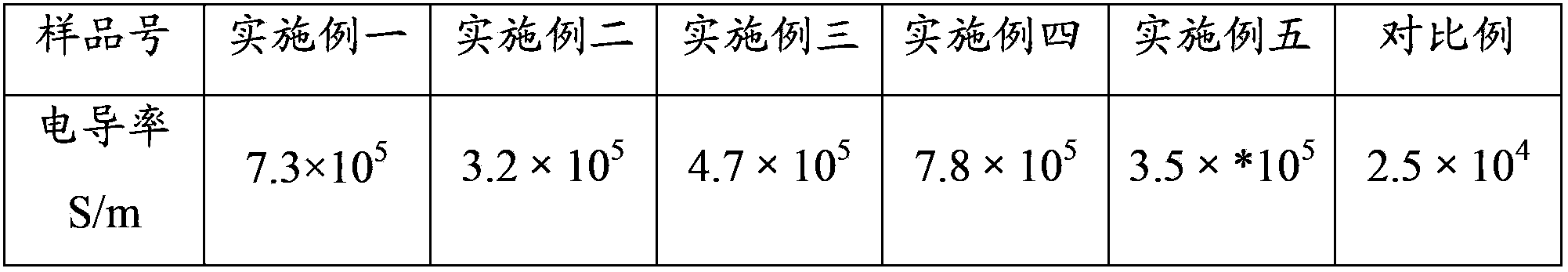

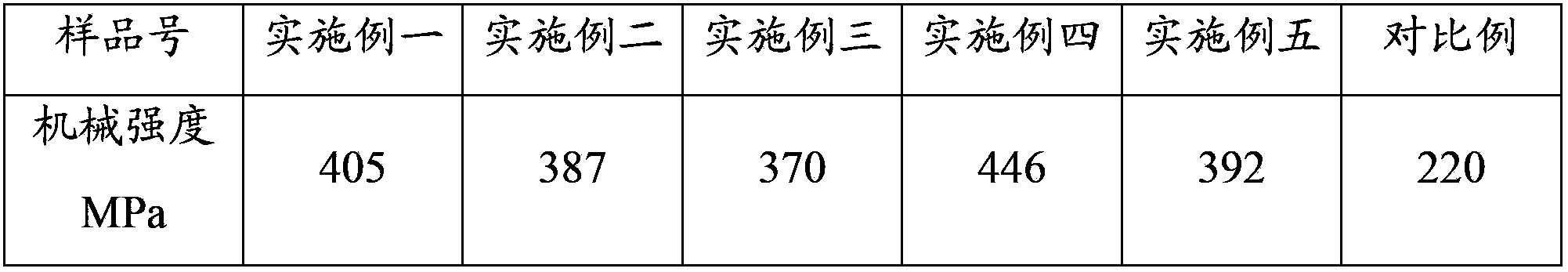

Examples

Embodiment 1

[0037] A preparation method of nitrogen-doped graphene / metal composite current collector, comprising the following steps:

[0038] (1) Add 1 g of graphite oxide to an aqueous solution containing 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid (1 g) to prepare a mixed solution of graphite oxide ionic liquid with a concentration of 0.5 g / L. Ultrasound for 0.5 hours;

[0039] (2) After the ultrasonication is completed, add 5 g of urea solution with a mass concentration of 20% to the above mixed solution. After ultrasonication for 10 minutes, put the obtained mixed solution into a hydrothermal reaction kettle and react at 80°C for 5 hours to obtain a stable nitrogen doped solution. Assorted graphene ionic liquid mixed solution, after cooling down to room temperature, add 10mmol / L copper nitrate solution 80mL, stir 5min, obtain the nitrogen-doped graphene ionic liquid mixed solution rich in copper nitrate;

[0040] (3) Use a mixed fiber membrane with a pore size of 50 n...

Embodiment 2

[0043] A preparation method of nitrogen-doped graphene / metal composite current collector, comprising the following steps:

[0044] (1) Take 1g of graphite oxide and add it to the DMF solution containing 1-hexadecyl-3-ethylimidazolium bromide salt ionic liquid (3g) to prepare a graphite oxide ionic liquid mixed solution with a concentration of 1g / L, and ultrasonically 1 hour;

[0045](2) After the ultrasonication is completed, add 1.25 g of urea solution with a mass concentration of 40% to the above mixed solution. After ultrasonication for 20 minutes, put the obtained mixed solution into a hydrothermal reaction kettle and react at 120°C for 8 hours to obtain stable nitrogen Doped graphene ionic liquid mixed solution, after cooling down to room temperature, add 5mmol / L cobalt nitrate solution 370mL, stir 20min, obtain the nitrogen-doped graphene ionic liquid mixed solution rich in cobalt nitrate;

[0046] (3) Vacuum filter the cobalt nitrate-rich nitrogen-doped graphene ionic ...

Embodiment 3

[0049] A preparation method of nitrogen-doped graphene / metal composite current collector, comprising the following steps:

[0050] (1) Take 1g of graphite oxide and add it to the NMP solution containing 1-dodecyl-3-methylimidazolium bromide salt ionic liquid (5g) to prepare a mixed solution of graphite oxide ionic liquid with a concentration of 3g / L, and ultrasonically 3 hours;

[0051] (2) After the ultrasonication is completed, add 0.6 g of urea solution with a mass concentration of 50% to the above mixed solution. After ultrasonication for 30 minutes, put the obtained mixed solution into a hydrothermal reaction kettle and react at 150°C for 12 hours to obtain stable nitrogen Doped graphene ionic liquid mixed solution, after cooling down to room temperature, add 1mmol / L nickel nitrate solution 3L, stir 5min, obtain the nitrogen-doped graphene ionic liquid mixed solution rich in nickel nitrate;

[0052] (3) Use a cellulose acetate membrane with a pore size of 200 nm to vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com