Graphene-metal-poly(m-phenylenediamine) plural gel as well as quick preparation and application methods thereof

A polym-phenylenediamine, composite gel technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the complex synthesis process, residual toxic monomers, and harsh reaction conditions. and other problems, to achieve the effect of high reaction efficiency, efficient and fast reaction, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

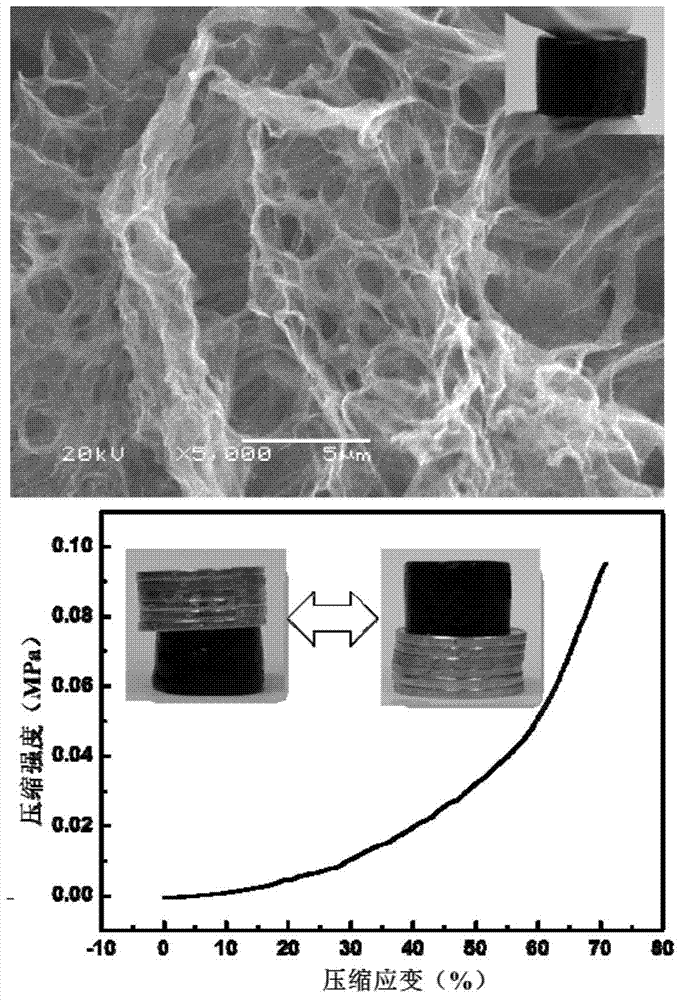

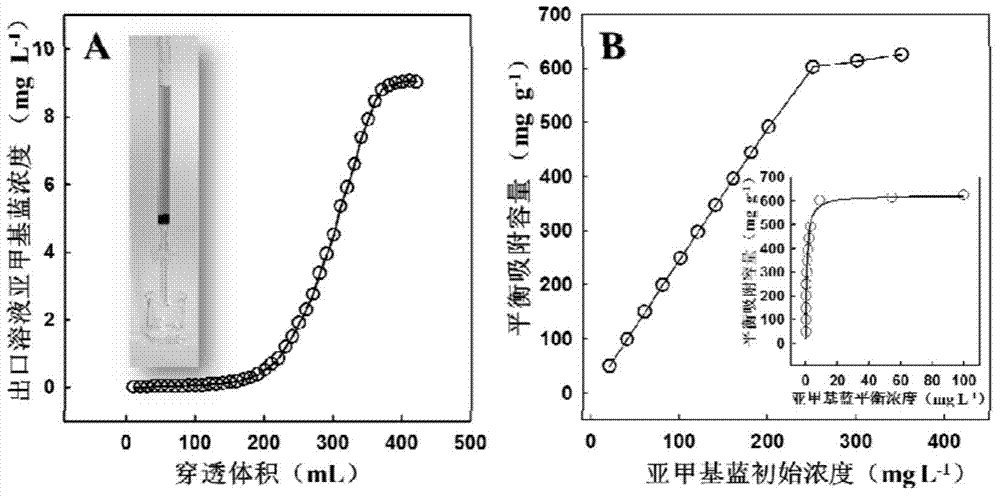

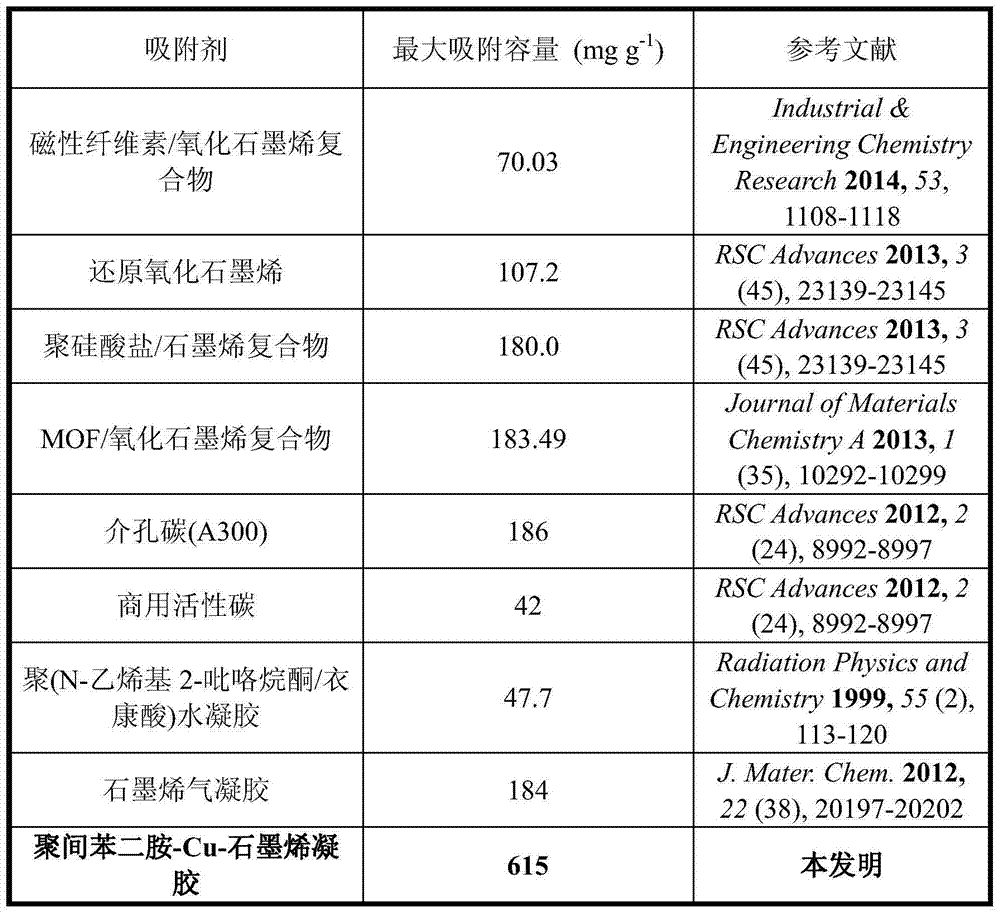

[0026] Embodiment 1: Synthetic graphene-copper-poly-m-phenylenediamine gel.

[0027] Slowly add 5g graphite powder to 30g KMnO under ice bath 4 and 120mL of concentrated sulfuric acid mixed solution, after stirring evenly, raise the temperature to 35°C for 30min, add 500mL of water, raise the temperature to 85°C for 2h, add 200mL of 30%H 2 o 2 , sufficient suction filtration and dialysis to remove impurity ions, and the product is graphene oxide. Make 5ml concentration to 5mg mL -1 The graphene oxide was ultrasonically dispersed for 1 h to obtain a uniform dispersion of graphene oxide. Dilute 1mL concentration to 10mg mL -1 The m-phenylenediamine solution with 0.1mL concentration is 40mg mL -1 CuCl 2 2H 2 The O solution was mixed and quickly added to the graphene oxide dispersion under ultrasound to form a GO-Cu-mPD gel (t≤1min). The gel was reacted at 95°C for 1 h to obtain rGO-Cu-PmPD gel. By measuring the residual liquid organic matter content (TOC method) and meta...

Embodiment 2

[0028] Embodiment 2: Synthetic graphene-copper-poly-m-phenylenediamine gel.

[0029] The preparation of graphene oxide is the same as in Example 1. Make 5ml concentration to 2mg mL -1 The graphene oxide was ultrasonically dispersed for 1 h to obtain a uniform dispersion of graphene oxide. Dilute 1mL concentration to 10mg mL -1 m-Phenylenediamine solution with a concentration of 0.1mL to 40mgmL -1 CuCl 2 2H 2O solution was mixed and quickly added to the graphene oxide dispersion under ultrasonication. After standing still for 1 min, the GO-Cu-mPD gel was formed, and the gel was reacted at 90°C for 1 h to obtain the rGO-Cu-PmPD gel. The monomer conversion rate is as high as 99.5%, and the metal ion chelation rate is 94.7%.

Embodiment 3

[0030] Embodiment 3: Synthetic graphene-copper-poly-m-phenylenediamine gel.

[0031] The preparation of graphene oxide is the same as in Example 1. Make 5ml concentration to 5mg mL -1 The graphene oxide was ultrasonically dispersed for 1 h to obtain a uniform dispersion of graphene oxide. Dilute 1mL concentration to 20mg mL -1 m-Phenylenediamine solution with a concentration of 0.2mL to 40mgmL -1 CuCl 2 2H 2 O solution was mixed and quickly added to the graphene oxide dispersion under ultrasonication. After standing still for 1 min, the GO-Cu-mPD gel was formed, and the gel was reacted at 80°C for 2 h to obtain the rGO-Cu-PmPD gel. The monomer conversion rate is as high as 99.1%, and the metal ion chelation rate is 92.9%

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com