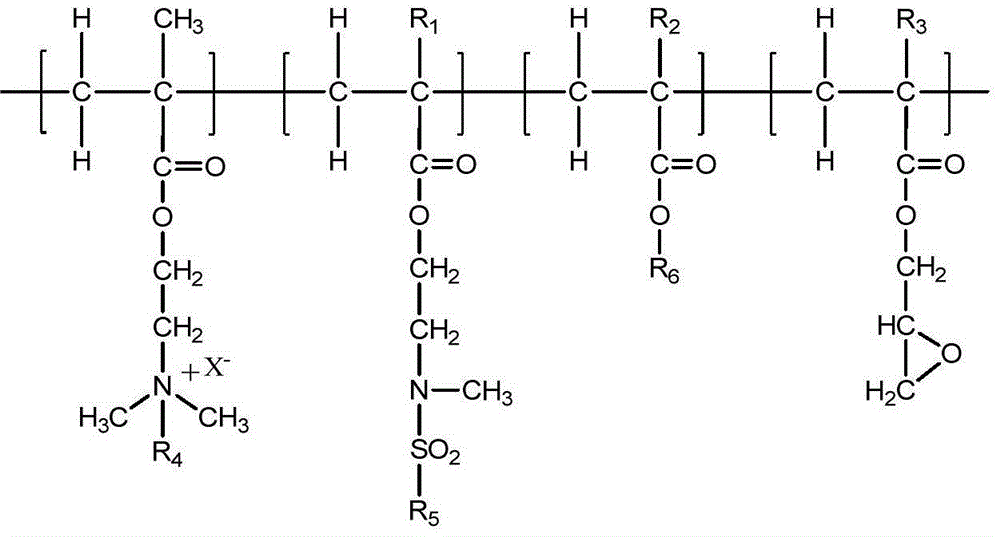

A kind of antibacterial modified low surface energy marine antifouling coating resin and preparation method thereof

A low surface energy, marine antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as poor adhesion, limited application scope, etc. Marine environment, fast film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

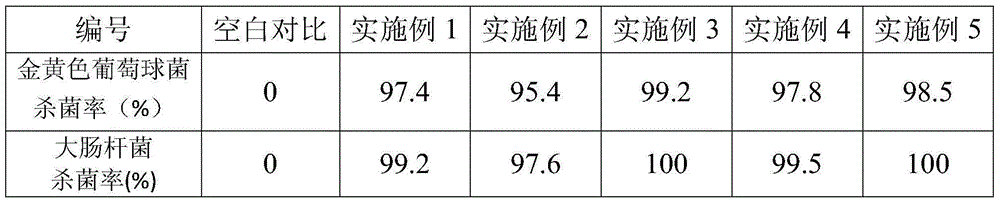

Examples

preparation example Construction

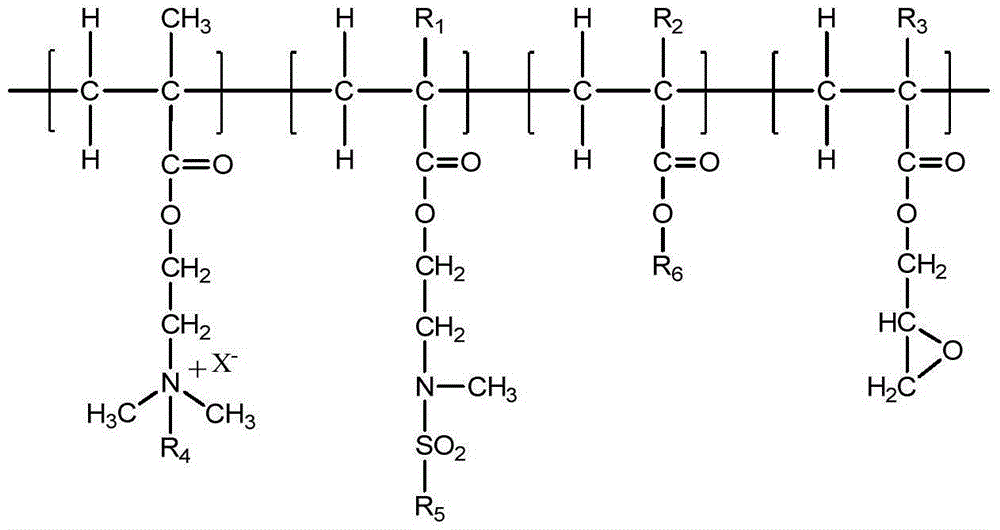

[0022] The preparation method of the antibacterial modified low surface energy type marine antifouling coating resin of the present invention comprises the following steps:

[0023] 1. Dissolve 0.5-1.5 parts by weight of initiator in 10-30 parts by weight of organic solvent, preheat to 55°C-95°C to obtain the first solution;

[0024] 2. 10-50 parts by weight of methacrylate quaternary ammonium salt monomer, 10-50 parts by weight of fluorocarbon chain acrylate monomer, 20-70 parts by weight of hydrocarbon chain acrylate monomer, 20-70 parts by weight The epoxy acrylate monomer, the initiator of 1.5-4.5 parts by weight and the chain transfer agent of 0.5-6 parts by weight are dissolved in the organic solvent of 20-90 parts by weight to obtain the second solution;

[0025] 3. Slowly add the second solution obtained in step 2 to the first solution obtained in step 1, and control the rate of addition to 0.5-2mL / s; after adding, keep warm for 4-6 hours, and add 0.5-1.5 parts by weig...

Embodiment 1

[0034] (1) Dissolve 0.5g of 2,2’‐azobisisobutyronitrile in 10g of butyl acetate, preheat to 55°C to obtain the first solution;

[0035] (2) Mix 10g methacryloyloxyethyl benzyl dimethyl ammonium chloride, 10g [N-methyl perfluorohexanesulfonamido] ethyl methacrylate, 20g methyl methacrylate, 20g formazan Glycidyl acrylate, 1.5g 2,2'-azobisisobutyronitrile and 0.5g dodecyl mercaptan were dissolved in 20g butyl acetate to obtain a second solution;

[0036] (3) Slowly add the second solution to the first solution dropwise, and control the dropping rate to 0.5mL / s; ℃, keep warm for 4 hours to obtain a resin solution, add methanol 5 times the volume of the resin solution to precipitate the polymerization reaction product, centrifuge, and dry in vacuum to obtain an antibacterial modified low surface energy marine antifouling coating resin.

Embodiment 2

[0038] (1) Dissolve 0.5g of 2,2’‐azobisisobutyronitrile in 10g of ethylene glycol ethyl ether acetate, preheat to 55°C to obtain the first solution;

[0039] (2) Mix 10g of methacryloyloxyethyl n-dodecyldimethylammonium bromide, 10g of [N-methyl perfluorobutanesulfonamido] ethyl methacrylate, 40g of methyl acrylate, 40g Glycidyl methacrylate, 3g 2,2'-azobisisobutyronitrile and 3g dodecyl mercaptan were dissolved in 60g ethylene glycol ether acetate to obtain the second solution;

[0040] (3) Slowly add the second solution to the first solution dropwise, and control the dropping rate to 1mL / s; after the addition, keep warm for 6 hours, add 1g of 2,2'‐azobisisobutyronitrile, and raise the temperature to 105°C. Insulate for 4 hours to obtain a resin solution, add n-hexane 10 times the volume of the resin solution to precipitate the polymerization reaction product, centrifuge, and vacuum dry to obtain an antibacterial modified low surface energy marine antifouling coating resin. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com