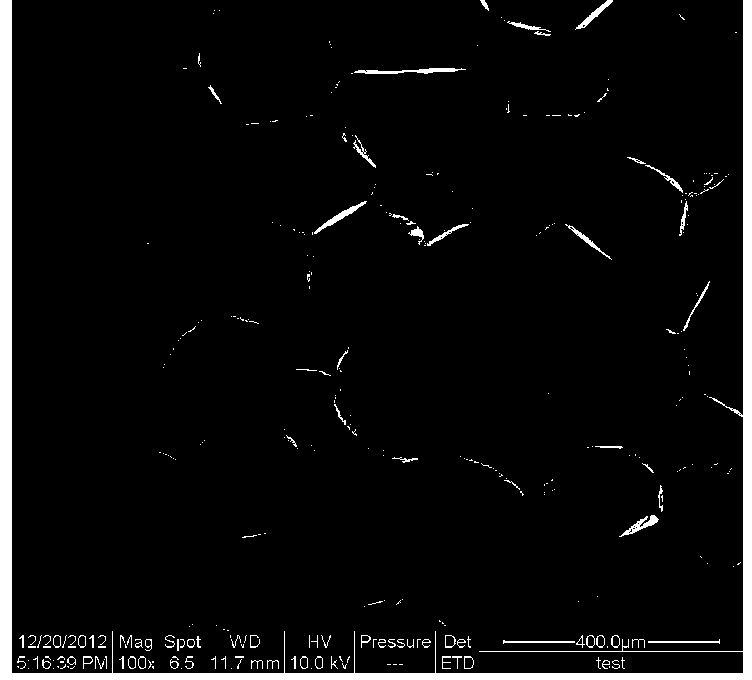

Method for preparing honeycomb-type multiporous foam carbon with high specific surface area from larix gmelini sawdust

A high specific surface area, porous foam technology, applied in the preparation/purification of carbon, etc., can solve the problems of poor strength of foamed carbon, limited application fields, etc., and achieve the effects of reducing environmental burden, simplifying process, and easy synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

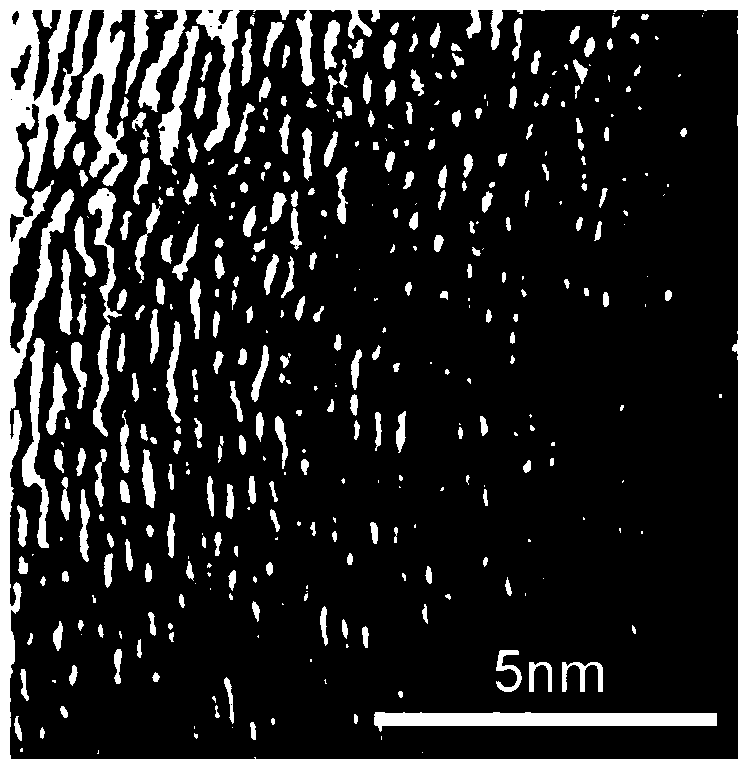

Method used

Image

Examples

Embodiment 1

[0022] (1) Add larch sawdust (80 mesh, dry at 105°C for 8 hours), phenol, concentrated sulfuric acid (98%) and concentrated phosphoric acid (85%) to a four-necked bottle at a ratio of 20g:60g:1mL:1.7mL , install a stirrer and a condenser, heat it, react at reflux temperature (120-140°C) for 1 hour, cool to room temperature, add about 130mL of methanol, stir well, and filter. The filtrate was neutralized to neutral with sodium carbonate, filtered to remove insoluble matter such as salt, and methanol was distilled off under reduced pressure to obtain brown liquefied larch.

[0023] (2) Add 100mL of formaldehyde solution (37%) and 1g of sodium hydroxide for every 20g of liquefied larch sawdust, stir, heat up to 50-60°C, keep warm for 0.5h, add ethanol-dissolved PEG2000 (accounting for about 8% of larch sawdust), continue to react for 1.5h, then heat and reflux at 90-98°C for 1h, cool the product to 60°C, react at this temperature for 0.5h, adjust the pH value to neutral, reduce ...

Embodiment 2

[0027] (1) Add larch sawdust (80 mesh, dry at 105°C for 8 hours), phenol, concentrated sulfuric acid (98%) and concentrated phosphoric acid (85%) to a four-necked bottle at a ratio of 20g:60g:1mL:1.7mL , install a stirrer and a condenser, heat it, react at reflux temperature (120-140°C) for 1 hour, cool to room temperature, add about 130mL of methanol, stir well, and filter. The filtrate was neutralized to neutral with sodium carbonate, filtered to remove insoluble matter such as salt, and methanol was distilled off under reduced pressure to obtain brown liquefied larch.

[0028] (2) Add 100mL of formaldehyde solution (37%) and 1g of sodium hydroxide for every 20g of liquefied larch sawdust, stir, heat up to 50-60°C, keep warm for 0.5h, add ethanol-dissolved PEG2000 (accounting for about 8% of larch sawdust), continue to react for 1.5h, then heat and reflux at 90-98°C for 1h, cool the product to 60°C, react at this temperature for 0.5h, adjust the pH value to neutral, reduce ...

Embodiment 3

[0031] (1) Add larch sawdust (80 mesh, dry at 105°C for 8 hours), phenol, concentrated sulfuric acid (98%) and concentrated phosphoric acid (85%) to a four-necked bottle at a ratio of 20g:60g:1mL:1.7mL , install the stirrer and

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com