Polyolefin plastic light-biodegradable modified additive as well as preparation and application thereof

A technology of biodegradation and polyolefin, which is applied in the field of polymers, can solve the problems of plastic mechanical properties degradation, affecting plastic degradation performance, uneven distribution of photodegradation, etc., achieve small addition, controllable degradation time, and solve white pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Weigh 100g of polyethylene and put it into the reaction kettle, start stirring, introduce air, and gradually increase the temperature. After reaching 140°C, take samples to measure the acid value and molecular weight every 30 minutes; when the acid value increases to 5mg(KOH) / g or more, Lower the reaction temperature to 130°C and continue the reaction for 16 hours to obtain oxidized polyethylene with an acid value of 30 mg(KOH) / g, whose structural formula is:

[0058]

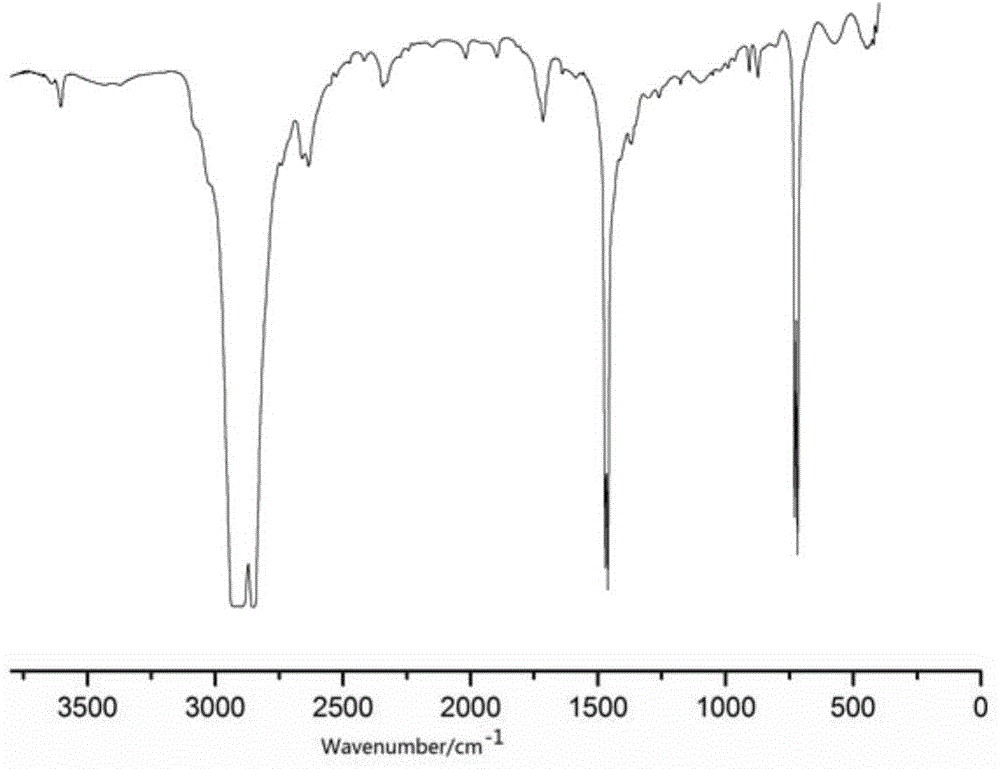

[0059] For structure verification data see figure 1 .

[0060] Add the above 100g oxidized polyethylene to 100mL xylene and heat to melt, then add the methanol solution of cobalt hydroxide according to the carboxyl group of oxidized polyethylene to cobalt molar equivalent ratio of 2:1 (the volume (or mass) concentration of cobalt hydroxide is 5%) , and reacted at 130°C for 3 hours; the solvent was removed under reduced pressure to prepare a modified oxidized polyethylene containing 1.4% (mass percent...

Embodiment 2

[0066] Weigh 100g of polypropylene and put it into the reaction kettle, start stirring, introduce air, gradually raise the temperature, and after reaching 140°C, take samples at regular intervals to measure the acid value and molecular weight. When the acid value increases to above 5 mg (KOH) / g, lower the reaction temperature to 130°C and continue the reaction for 16 hours to obtain oxidized polypropylene with an acid value of 38 mg (KOH) / g.

[0067] Add a small amount of xylene to the above 100 g of oxidized polypropylene and heat to melt, then add a methanol solution of cerium hydroxide according to the carboxyl group of oxidized polypropylene to cerium molar equivalent ratio of 4:1, and react at 130°C for 3 hours. The solvent was removed under reduced pressure to prepare modified oxidized polypropylene containing 1.8% cerium.

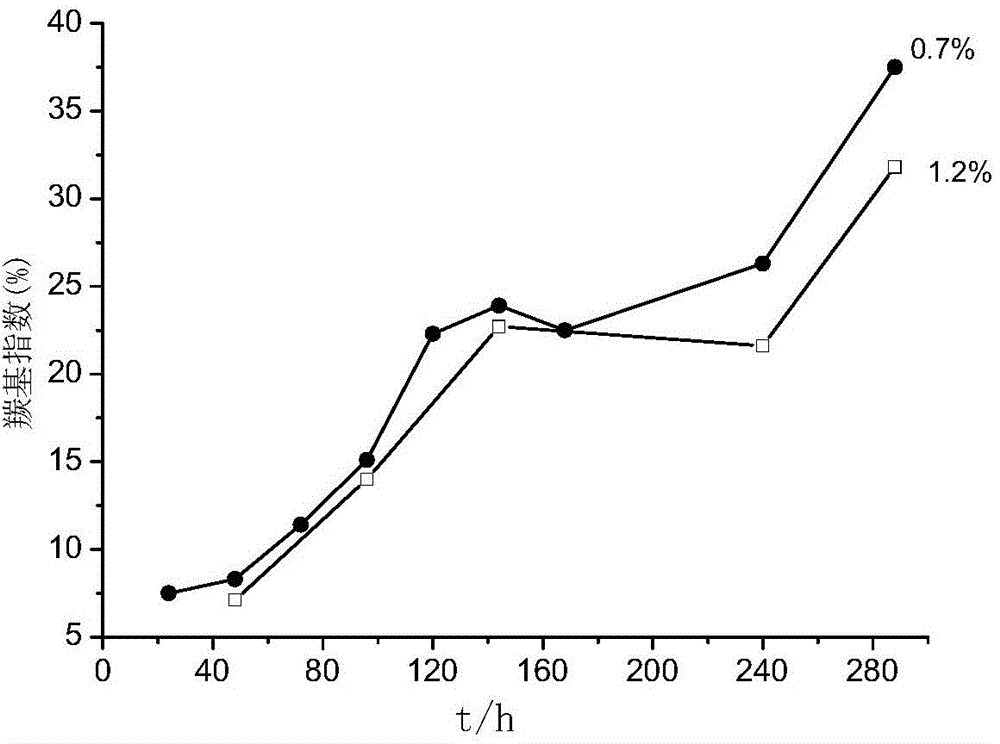

[0068] Mix 1.2 g of the obtained cerium-containing controllable photobiodegradable polypropylene additive with 0.08 g of a polymeric antioxidant or ...

Embodiment 3

[0071] Dissolve 100g of polyolefin and 8g of maleic acid in 100mL of xylene, protect with nitrogen, heat the oil bath to 120°C, add 0.08g of benzoyl peroxide in batches every 20 minutes (0.08g in total), and stir for 5 hours after termination. After cooling to room temperature, about three times the volume of ethanol was poured into the product to obtain a white precipitate. Suction filter with Buchner funnel and soak overnight in acetone. Then dissolve with xylene and carry out secondary precipitation, and repeat the precipitation 2 to 3 times to wash away the residual maleic acid monomer. The product is dried in an oven at 60°C to constant weight to obtain a maleic acid grafted modified polyolefin.

[0072] Add a small amount of xylene to the above 100 g of maleic acid grafted polyolefin and heat to melt, then add nickel hydroxide methanol solution according to the carboxyl group of maleic acid grafted polyolefin to nickel molar equivalent ratio of 2:1, and react at 130°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com