Method for preparing methylene carbonic ester by using enzymic method

A technology of methylene carbonate and enzymatic preparation, applied in fermentation and other directions, can solve problems such as high price, and achieve the effects of high universality, mild reaction conditions and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

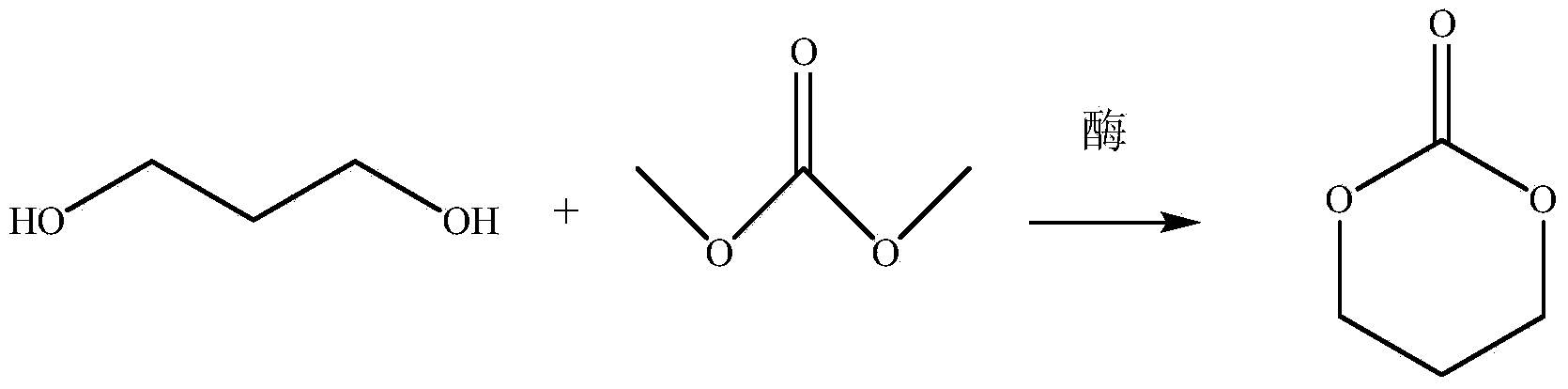

[0035] In the ionic liquid [Emim][PF 6 ]Candida antarctica lipase B (CALB) catalyzed the reaction of dimethyl carbonate and 1,3-propanediol to prepare 1,3-dioxane-2-one. Dimethyl carbonate and 1,3-propanediol at a ratio of 1:10, then add Candida antarctica lipase B with 3% of the total mass of dimethyl carbonate and 1,3-propanediol, stir the reaction in air, ionic liquid 2mL / g (based on ester weight, w / w), water content 1% (based on ester weight, w / w), reaction temperature 55°C, take the reaction solution for 1,3-dioxane at regular intervals - Analysis of 2-ketone content. Analysis process: Take 50 μL of the reaction solution and centrifuge to separate layers, take 10 μL of the upper layer sample, dissolve it in 290 μL cyclohexane, shake well, then add 300 μL of n-heptane (2 mg / mL) as an internal standard; The yield of 1,3-dioxan-2-one in the reactant was determined by chromatography, and the chromatographic column was SE-54 type. The specific test conditions are as follow...

Embodiment 2

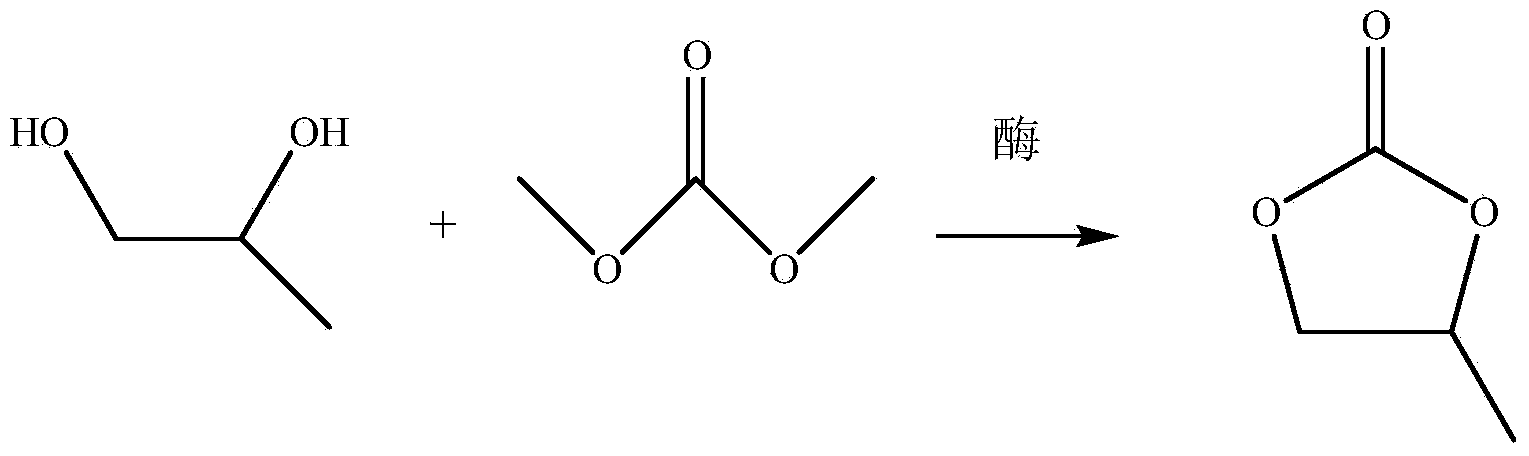

[0040] In the ionic liquid [Bmim][PF 6 ] Candida antarctica lipase B catalyzes the reaction of dimethyl carbonate and 1,2-propanediol to prepare propylene carbonate. The reaction conditions are as follows: add dimethyl carbonate and 1,2- Propylene glycol, then add Candida antarctica lipase B with a total mass of 1.5% of dimethyl carbonate and 1,2-propanediol, stir the reaction in air, ionic liquid 2mL / g (based on ester weight, v / w), water content 1 % (based on ester weight, w / w), the reaction temperature was 60°C, and the reaction solution was taken at regular intervals for analysis of propylene carbonate content. Analysis process: Take 50 μL of the reaction solution and centrifuge to separate layers, take 10 μL of the upper layer sample, dissolve it in 290 μL cyclohexane, shake well, then add 300 μL of n-heptane (2 mg / mL) as an internal standard; The yield of propylene carbonate in the reactant was determined by chromatography, and the chromatographic column was SE-54 type. ...

Embodiment 3

[0046] In ionic liquids [Emim][BF 4 ] Candida antarctica lipase B catalyzes the reaction of dimethyl carbonate and ethylene glycol to prepare ethylene carbonate. The reaction conditions are as follows: add dimethyl carbonate and 1,2-propylene glycol in a molar ratio of 1:12 to the reaction vessel, Then add Candida antarctica lipase B with 12% total mass of dimethyl carbonate and 1,2-propanediol, stir in the air, ionic liquid 2mL / g (based on ester weight, v / w), water content 1% ( Based on ester weight (w / w), the reaction temperature is 25-65° C., and after 48 hours of reaction time, the reaction solution is taken for ethylene carbonate content analysis. Analysis process: Take 50 μL of the reaction solution and centrifuge to separate layers, take 10 μL of the upper layer sample, dissolve it in 290 μL cyclohexane, shake well, then add 300 μL of n-heptane (2 mg / mL) as an internal standard; The yield of ethylene carbonate in the reactant was determined by chromatography, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com