Ganoderma sinense polysaccharide dispersible tablet and preparation method thereof

A Zizhi polysaccharide and dispersible tablet technology, which is applied in the field of medicine, can solve the problems of Zizhi polysaccharide dispersible tablet hardness, disintegration speed not meeting the requirements, undiscovered Zizhi polysaccharide dispersible tablet, affecting the quality and production efficiency of the dispersible tablet, and achieving Improve the taste of the solution, confirm the therapeutic effect, and have good compression molding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

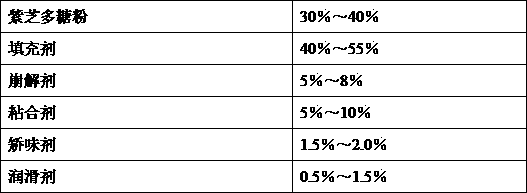

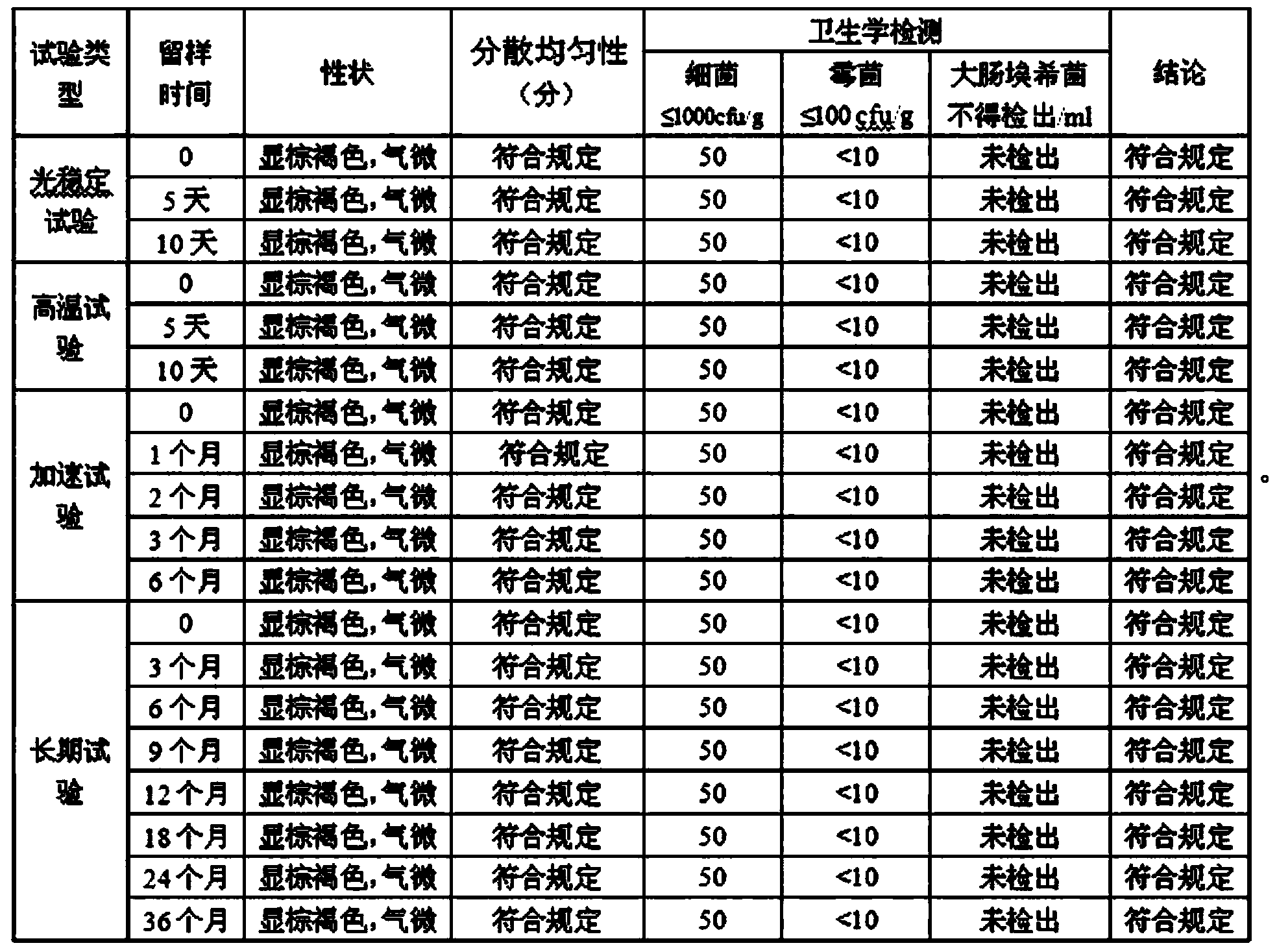

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Zizhi polysaccharide powder:

[0033] Wash the Zizhi fruiting body and / or mycelium, drain, add water and decoct twice, decoct for 2 hours for the first time, filter the medicinal liquid with a 100-mesh filter cloth, add 5 times the amount of water to the dregs for the second Decoct for the second time for 2 hours, filter the medicinal liquid with a 100-mesh filter cloth, combine the medicinal liquid obtained from the second decoction, concentrate under reduced pressure to a clear paste with a relative density of 1.15 (heat measurement at 50°C), and add 95% Ethanol until the alcohol content reaches 62%, let it stand for 24 hours, take the supernatant to recover the ethanol until it has no alcohol smell, and the precipitate after recovering the ethanol is vacuum-dried at 60°C, and the moisture content of the dry extract is controlled within 3%. Put the paste into a high-efficiency pulverizer and pulverize it into fine powder, and pass through a 100-mesh sie...

Embodiment 2

[0035] Zizhi polysaccharide powder 35% by weight starch 30% by weight microcrystalline cellulose 12% by weight Crospovidone 5% by weight 4% starch slurry 15% by weight aspartame 1.2% by weight Sodium chloride 0.6% by weight Micropowder silica gel 1.2% by weight

[0036] Preparation:

[0037] Weigh each raw material, mix Zizhi polysaccharide powder, starch, microcrystalline cellulose, crospovidone, aspartame and sodium chloride evenly; use 4% starch slurry to make a soft material from the mixture, and pass through a 18-mesh sieve to make a soft material. Granules; dry the wet granules at 50°C to make the water content of the granules 3.0%; pass the dried granules through a 16-mesh sieve for granulation; add micropowder silica gel to the granulated granules, mix well, and press into dispersible tablets. The dispersible tablet completely disintegrated within 3 minutes and passed through the No. 2 sieve.

Embodiment 3

[0039] Zizhi polysaccharide powder 23% by weight Calcium sulfate 60% by weight Sodium carboxymethyl starch 5.5% by weight Crospovidone 1.5% by weight 30% ethanol 5% by weight sodium saccharin 2.5% by weight talcum powder 2.5% by weight

[0040] Preparation:

[0041] Weigh each raw material, mix the purple polysaccharide powder, calcium sulfate, sodium carboxymethyl starch, crospovidone, and sodium saccharin evenly; use 30% ethanol to make a soft material from the mixture, and granulate through a 16-mesh sieve; Dry at 70°C to make the water content of the granules 3.5%; pass the dried granules through a 16-mesh sieve for granulation; add talcum powder to the granulated granules, mix evenly, and press into dispersible tablets. The dispersible tablet completely disintegrated within 3 minutes and passed through the No. 2 sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com