Coal asphalt material for paving high-grade road and preparation method of coal asphalt material

A technology of coal tar pitch and high grade is applied in the field of coal tar pitch material for grade road paving and its preparation. The effect of simple modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

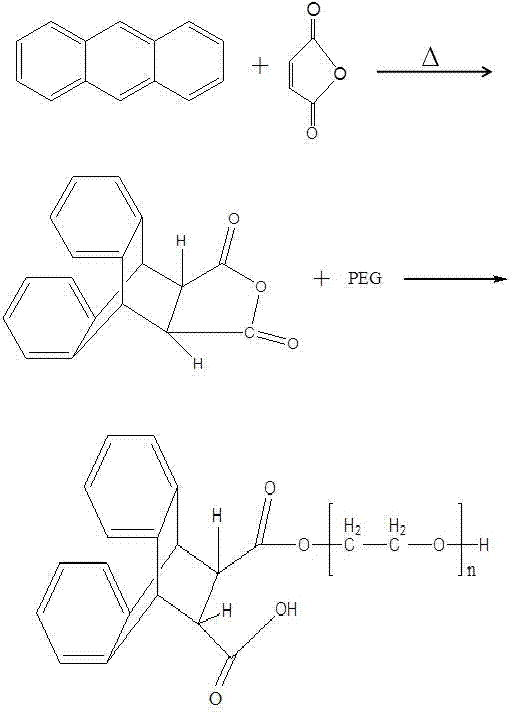

Method used

Image

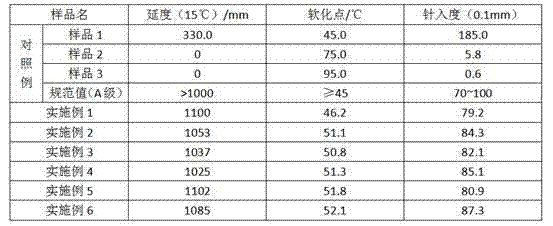

Examples

Embodiment 1

[0029] Step 1: Take 150 parts by weight of medium and low temperature coal tar pitch, and heat it at 120°C to obtain a viscous substance;

[0030] Step 2: Add 5 parts by weight of plasticizer, stir for 1 hour, then transfer to a round bottom flask, add 10 parts by weight of acid anhydride compound, and react at 120°C for 2 hours;

[0031] Step 3: Add 5 parts by weight of polyethylene glycol, react for another 2 hours, and dehydrate to obtain a high-grade coal tar pitch material for road paving.

[0032] In step one, the medium and low temperature coal tar pitch whose softening point is 65°C is selected;

[0033] In step 2, the plasticizer is selected from mono-anthracene oil, di-anthracene oil, mixed anthracene oil, and dioctyl phthalate;

[0034] In step 2, the acid anhydride compound is selected from maleic anhydride and tung oil anhydride;

[0035] In step 3, polyethylene glycol is selected from PEG 300 and PEG 400.

Embodiment 2

[0037] Step 1: Take 150 parts by weight of medium and low temperature coal tar pitch, and heat it at 135°C to obtain a viscous substance;

[0038] Step 2: Add 15 parts by weight of a plasticizer, stir for 1 hour, then transfer to a round bottom flask, add 15 parts by weight of an acid anhydride compound, and react at a temperature of 150° C. for 2 hours;

[0039] Step 3: adding 10 parts by weight of polyethylene glycol, reacting for another 2 hours, and dehydrating to obtain a high-grade coal tar pitch material for road paving.

[0040] In step 1, the medium and low temperature coal tar pitch whose softening point is 80°C is selected;

[0041] In step 2, the plasticizer is selected from dioctyl terephthalate, octyl tridecyl phthalate, dicyclohexyl phthalate, trioctyl trimellitate, triglycerin trimellitate ester;

[0042] In step 2, the acid anhydride compound is selected from tungalic anhydride, polyazelaic anhydride, and trimellitic anhydride;

[0043] In step 3, polyethyl...

Embodiment 3

[0045] Step 1: Take 150 parts by weight of medium and low temperature coal tar pitch, and heat it at 150°C to obtain a viscous substance;

[0046] Step 2: Add 25 parts by weight of plasticizer, stir for 1 hour, then transfer to a round bottom flask, add 20 parts by weight of acid anhydride compound, and react at 180°C for 3 hours;

[0047] Step 3: adding 15 parts by weight of polyethylene glycol, reacting for another 3 hours, and dehydrating to obtain a high-grade coal tar pitch material for road paving.

[0048] In step one, the medium and low temperature coal tar pitch whose softening point is 95°C is selected;

[0049] In step 2, the plasticizer is selected from epoxy soybean oil, tall oil, aromatic oil, animal oleic acid, vegetable oleic acid;

[0050]In step 2, the acid anhydride compound is selected from the adducts of trimellitic anhydride and bisphenol A (the curing agent prepared by mixing bisphenol A and trimellitic anhydride at a molar ratio of 1:2 at 180°C for 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com