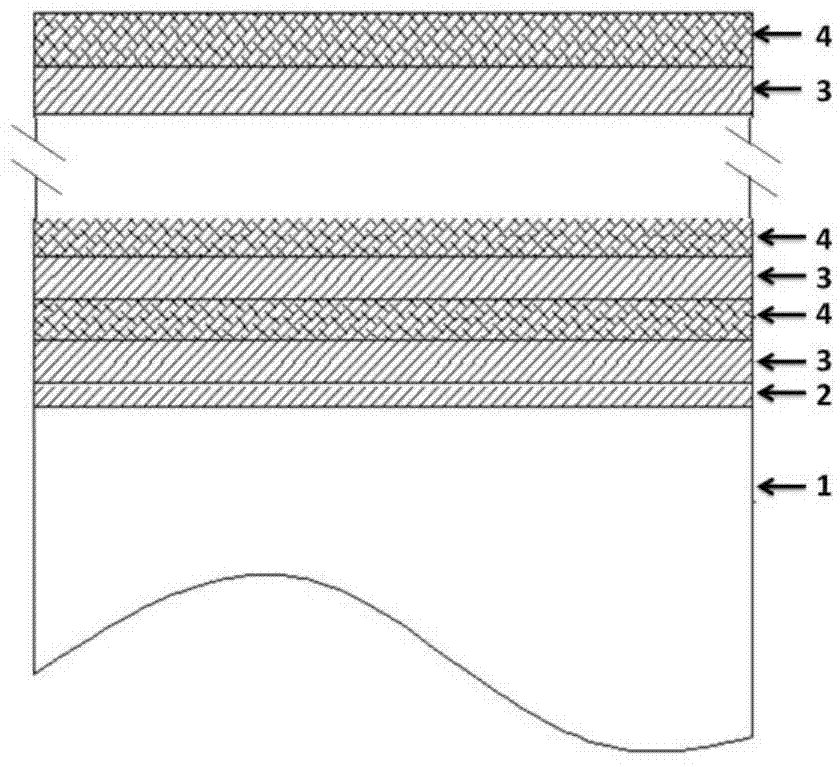

Method for preparing antibacterial diamond-like carbon/hydroxyapatite gradient multi-element nano coating

A technology of hydroxyapatite and composite hydroxyapatite, which is applied in the field of preparation of medical composite coating materials, and can solve the problems of reduced efficacy of antibiotics and infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The substrate material is a titanium-based alloy, cobalt-based alloy or stainless steel for artificial joint replacement. After ultrasonic cleaning and pretreatment, it is placed in a magnetron sputtering vapor deposition system, and the following steps are carried out: (a) argon gas into the vacuum chamber, keep the air pressure at 1-1.5Pa, turn on the bias power supply and adjust it to –1000V, and perform argon ion discharge cleaning and activation on the surface of the substrate for 20 minutes; (b) use a high-purity Ti target as the sputtering target, Ar ion bombardment, the control current is 2.0A, the bias voltage is –1000V, the duty cycle is 50%, and the sputtering deposition time is 20 minutes; (c) single-layer diamond-like carbon deposition, the Ti target sputtering process continues, and at the same time into high-purity CH 4 , control flow rate 8sccm as initial, increase 2sccm every 2 minutes, until added to 40sccm, discharge pressure is 1.0Pa, c...

Embodiment 2

[0021] Embodiment 2: The base material is a titanium-based alloy, cobalt-based alloy or stainless steel for artificial joint replacement. After ultrasonic cleaning and pretreatment, it is placed in a magnetron sputtering vapor deposition system, and the following steps are carried out: (a) argon gas into the vacuum chamber, keep the air pressure at 1-1.5Pa, turn on the bias power supply and adjust it to –1000V, and perform argon ion discharge cleaning and activation on the surface of the substrate for 20 minutes; (b) use a high-purity Ti target as the sputtering target, Ar ion bombardment, the control current is 2.0A, the bias voltage is –1000V, the duty cycle is 50%, and the sputtering deposition time is 20 minutes; (c) single-layer diamond-like carbon deposition, the Ti target sputtering process continues, and at the same time into high-purity CH 4 , control flow rate 8sccm as initial, increase 2sccm every 2 minutes until it reaches 40sccm, discharge pressure is 1.0Pa, contr...

Embodiment 3

[0022] Embodiment 3: The substrate material is a titanium-based alloy, cobalt-based alloy or stainless steel for artificial joint replacement. After ultrasonic cleaning and pretreatment, it is placed in a magnetron sputtering vapor deposition system, and the following steps are carried out: (a) argon gas into the vacuum chamber, keep the air pressure at 1-1.5Pa, turn on the bias power supply and adjust it to –1000V, and perform argon ion discharge cleaning and activation on the surface of the substrate for 20 minutes; (b) use a high-purity Ti target as the sputtering target, Ar ion bombardment, the control current is 2.0A, the bias voltage is –1000V, the duty cycle is 50%, and the sputtering deposition time is 20 minutes; (c) single-layer diamond-like carbon deposition, the Ti target sputtering process continues, and at the same time into high-purity CH 4 , control flow rate 8sccm as initial, increase 2sccm every 2 minutes until it reaches 40sccm, discharge pressure is 1.0Pa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com