Construction of arginase production engineering bacteria and application of arginase production engineering bacteria in production of L-ornithine

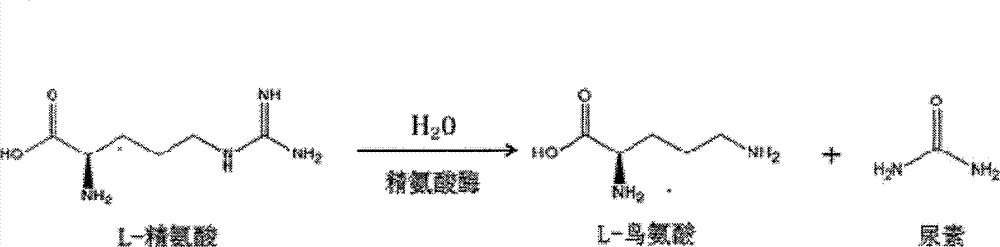

A technology of arginase and arginase gene, which is applied in the direction of bacteria, the use of vectors to introduce foreign genetic material, recombinant DNA technology, etc., can solve the problems of complex components, low yield, and difficult separation, so as to reduce production costs , The reaction speed is improved, which is beneficial to the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Construction of Genetic Engineering Bacteria Containing Arginase

[0048] (1) The arginase gene from Bacillus caldovelox (DSM411) (GenBank accession number: U48226 .1) Perform PCR amplification: Add LAtaq enzyme to the system, pre-denature at 94°C for 3 minutes, denature at 94°C for 30 seconds, anneal at 55°C for 30 seconds, extend at 72°C for 1.2 minutes, 30 cycles, and finally extend at 72°C for 10 minutes;

[0049] (2) Digest the target gene and expression vector pET28a at 37°C for 2 hours with restriction endonucleases Nco I and HindIII;

[0050] (3) Use T4 ligase to ligate the target gene and plasmids pET20b and pET28a after digestion and gel recovery at 16°C for 10 h;

[0051] (4) Introduce the constructed expression plasmid into E.coli BL21(DE3), and culture it on the LB plate containing kanamycin for 12h;

[0052] (5) Perform PCR and enzyme digestion verification on the colony grown on the plate, carry out sequencing verification on the plasmid containing the ...

Embodiment 2

[0054] Conversion of L-arginine to L-ornithine by arginase obtained through expression and secretion

[0055] (1) Insert the genetically engineered bacteria of construction into LB slant medium and cultivate for 12h;

[0056] (2) Put a ring of slanted seeds into the LB medium and cultivate for 6 hours;

[0057] (3) Insert the seed solution into the LB fermentation medium and cultivate to OD 600 0.6, adding IPTG with a final concentration of 0.4mmol / L for induction, collecting the thalli after 6h, and washing the thalline twice with sterile normal saline;

[0058] (4) Put the thalli into the transformation solution for transformation, and the transformation conditions are as follows: the substrate arginine concentration is 160g / L, the transformation temperature is 50-70°C, the transformation time is 2-4h, and the shaker speed is 150rpm;

[0059] (5) Take an appropriate amount of conversion solution for detection and analysis

Embodiment 3

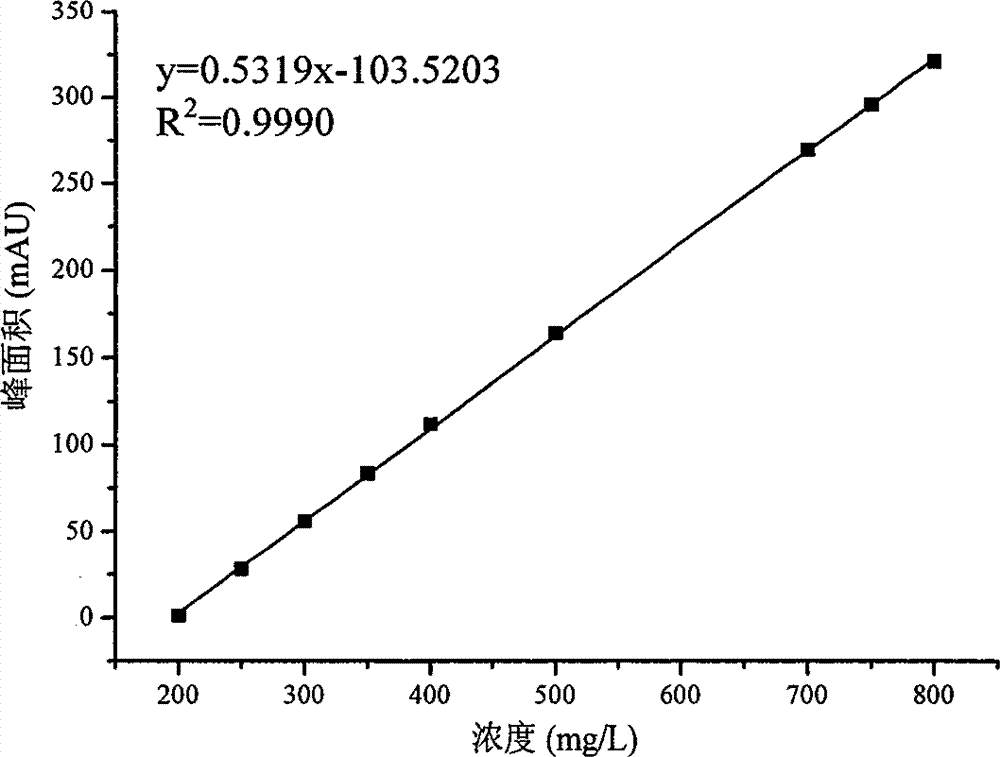

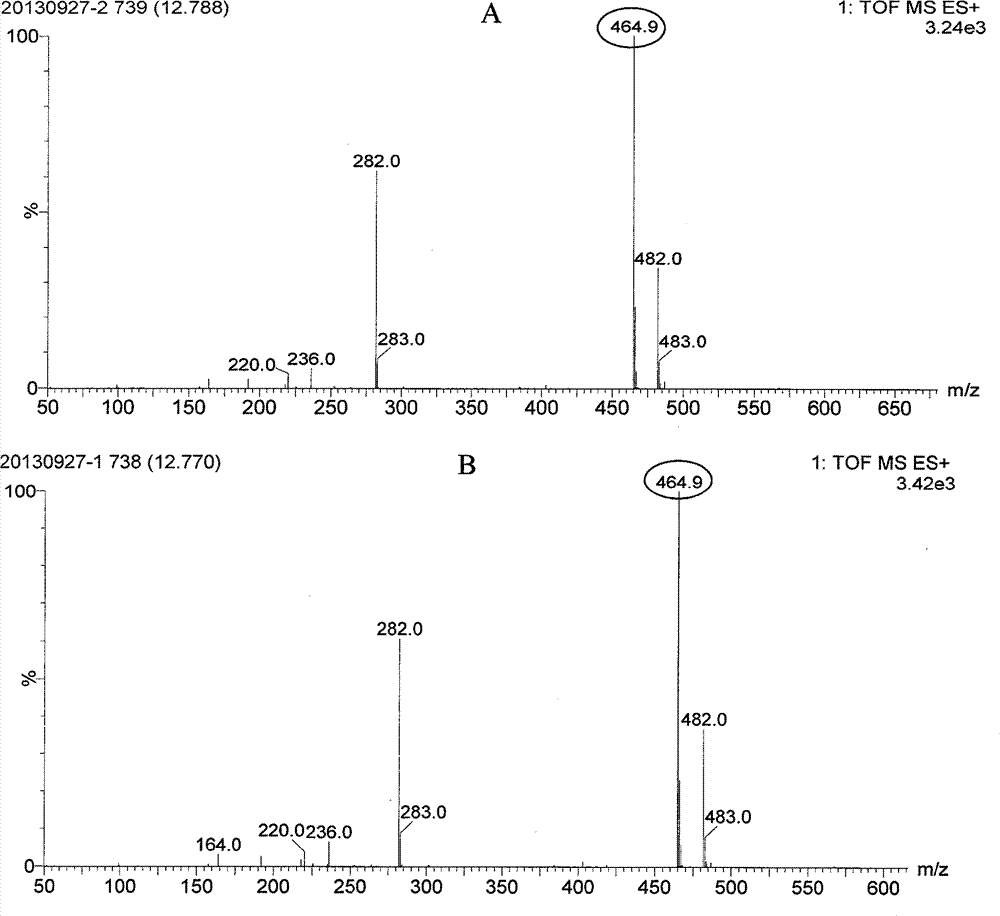

[0061] The transformation solution was centrifuged at 10,000 rpm for 2 minutes, the supernatant was collected, and a standard solution was prepared using L-ornithine hydrochloride as a standard. The moderately diluted supernatant and standard solution were respectively derivatized with 2,4-dinitrofluorobenzene, filtered through a 0.22 μm microporous membrane, and verified whether the product was L-ornithine by liquid chromatography-mass spectrometry. Determination of L-ornithine content by high performance liquid chromatography.

[0062] The relative molecular mass of the fermentation product and the standard sample is the same as measured by liquid chromatography-mass spectrometry (see image 3 ), it can be proved that the conversion product is L-ornithine.

[0063] The content of L-ornithine in the conversion solution was measured by high performance liquid chromatography, and it can be seen that after 4 hours, the output of L-ornithine reached 120.1 g / L, and the conversion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com