PEDOT (poly(3,4-ethylenedioxythiophene)):PSS (poly(sodium-p-styrenesulfonate)) water dispersion and preparation method thereof

A technology of dispersion and powder, which is applied in the field of organic semiconductors, can solve the problems of limited application development, electrical conductivity and film-forming properties, and low film conductivity, and achieves a simple and reliable preparation method, suitable for popularization and application, and repeatable good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one (comparative example)

[0036] Preparation of PEDOT:PSS Aqueous Dispersion Using PSS as Template

[0037] The PEDOT:PSS aqueous dispersion of the template that the preparation solid content is 2% with PSS, wherein, the mass ratio of PSS and EDOT is 6:1; The mass ratio of IPA and EDOT is 1:1; (NH 4 ) 2 S 2 o 8 The molar ratio with EDOT is 2:1; Fe 2 (SO 4 ) 3 The molar ratio to EDOT is 0.003:1.

[0038] Concrete preparation method and steps are as follows:

[0039] First, at room temperature, weigh 0.1g EDOT and 0.6gPSS in a 250ml reaction bottle, measure 20g of deionized water and stir to dissolve until clear, then weigh 0.1g of isopropanol, 0.00028mol (NH 4 ) 2 S 2 o 8 and 4.225×10 -6 molFe 2 (SO 4 ) 3 , Measure 15g of deionized water into the reaction flask, and react under stirring at 30-45°C to obtain an aqueous dispersion. During the reaction, samples were taken regularly to measure the conversion rate.

[0040] The prepared aqueous d...

Embodiment 2

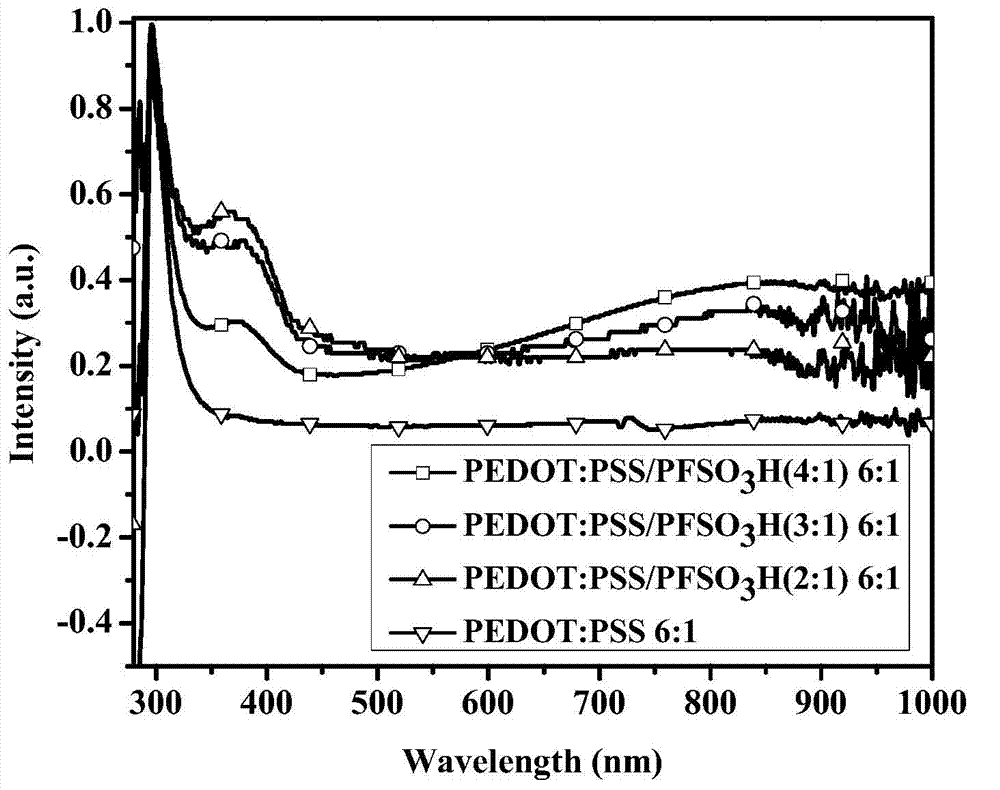

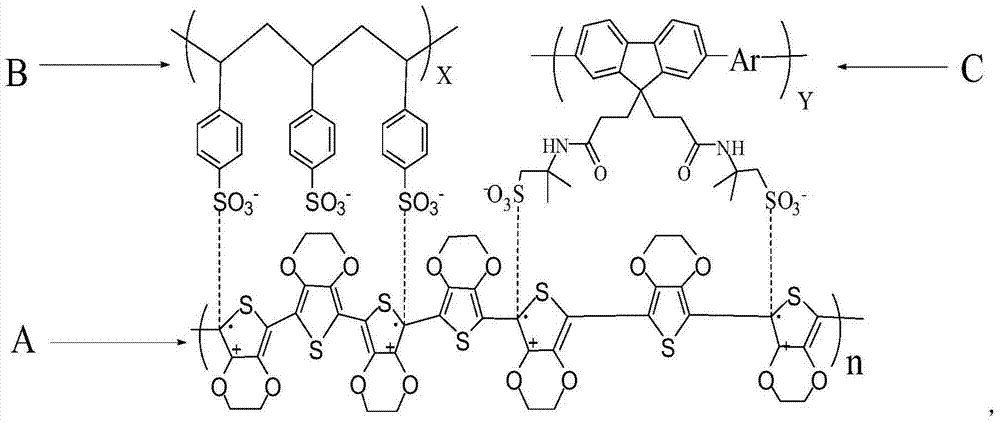

[0042] The PEDOT:PSS aqueous dispersion was prepared by using the copolymer of 9,9-dioctylfluorene and 9,9-di-(3-propylamide-2-methylpropanesulfonate)fluorene as a template.

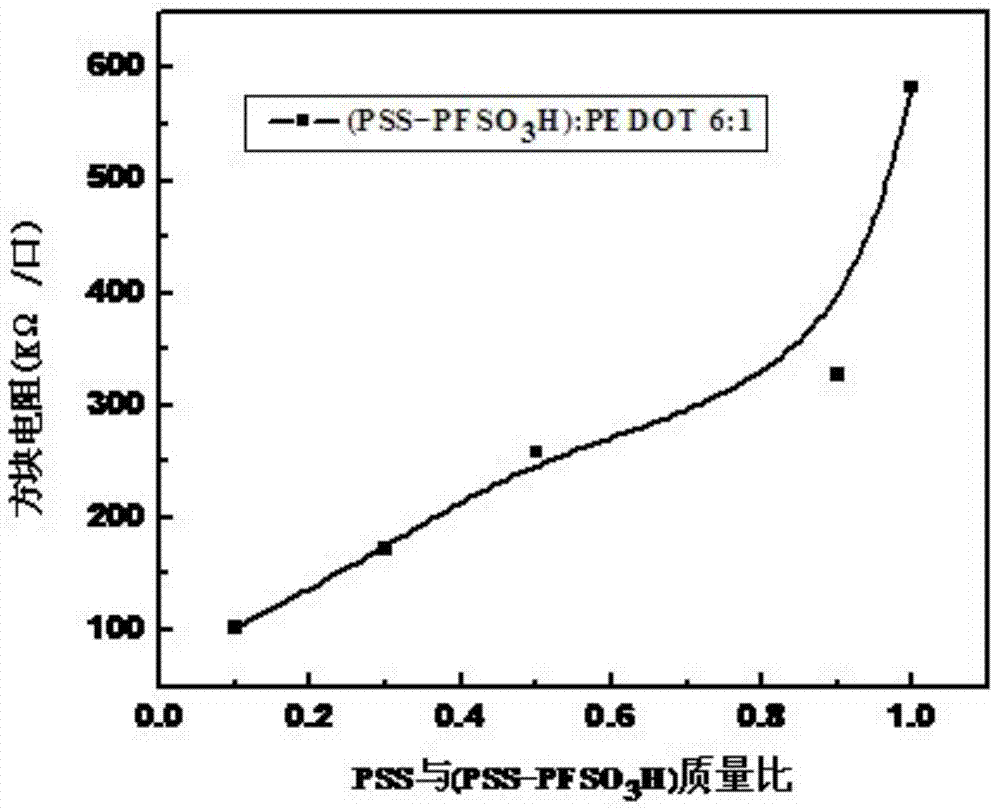

[0043] Aqueous dispersion of PEDOT:PSS with a solid content of 1% and a sulfonic acid conjugated polymer as a template was prepared. PSS and PFSO 3 The mass ratio of H is 0.5:1; PSS-PFSO 3 The mass ratio of H and EDOT is 0.5:1; the mass ratio of IPA and EDOT is 1:1; (NH 4 ) 2 S 2 o 8 The molar ratio with EDOT is 1.5:1; Fe(OTS) 3 The molar ratio with EDOT is 0.004:1; H 2 o 2 The molar ratio with EDOT is 2:1.

[0044] Concrete preparation method and steps are as follows:

[0045] First, weigh 0.1111g of 9,9-dioctylfluorene and 9,9-bis-(3-propylamide-2-methylpropanesulfonate sodium)fluorene in a 250ml reaction bottle at room temperature. Copolymer, 0.0555gPSS and 0.3333gEDOT, measure 25g deionized water and stir to dissolve until clear, then weigh 0.3333g of isopropanol, 0.0035mol (NH 4 ) 2 S 2...

Embodiment 3

[0048] The PEDOT:PSS aqueous dispersion was prepared by using the copolymer of 9,9-dioctylfluorene and 9,9-di-(3-propylamide-2-methylpropanesulfonate)fluorene as a template.

[0049] Aqueous dispersion of PEDOT:PSS with a solid content of 1% and a sulfonic acid conjugated polymer as a template was prepared. The mass ratio of PSS and PFSO3H is 10:1; the mass ratio of PSS-PFSO3H and EDOT is 1:1; the mass ratio of IPA and EDOT is 1:1; the molar ratio of (NH4)2S2O8 and EDOT is 0.5:1; Fe2 The molar ratio of (SO4)3 and EDOT is 0.002:1.

[0050] Concrete preparation method and steps are as follows:

[0051] First, weigh 0.0303 g of 9,9-dioctylfluorene and 9,9-bis-(3-propylamide-2-methylpropanesulfonate sodium)fluorene in a 250ml reaction flask at room temperature. Copolymer, 0.3030gPSS and 0.3333gEDOT, take 25g of deionized water and stir to dissolve until clear, then weigh 0.3333g of isopropanol, 0.0012mol(NH4)2S2O8 and 4.695×10-6molFe2(SO4)3, take 41.66 Add 2 g of deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com