Solid fluorescent nanometer microsphere as well as preparation method and application thereof

A fluorescent nanometer and solid technology, applied in the field of fluorescence detection, can solve the problems of weak fluorescence and poor uniformity of surface fluorescent microspheres, and achieve the effects of uniform fluorescence intensity, high signal amplification, and improved sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

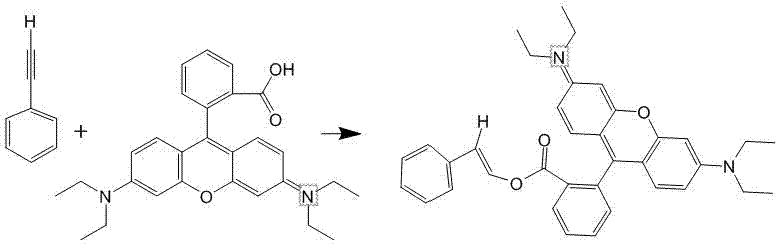

[0039] Embodiment 1: Synthesis of Entity Fluorescent Nanospheres

[0040] 1. Dissolve 1-10 mmol of Rhodamine B in 10 mL of DMSO.

[0041] 2. Dissolve 1-10mmol of phenylacetylene in 10mL of DMSO, and then mix it with Rhodamine B in DMSO.

[0042] 3. Add 20mL of 1-10mmol CuCl to the reaction system in step 2 2 Aqueous solution, adding 50-300mL of water to the mixed solution, stirring and reacting at room temperature for 2-4 hours at a speed of 300rpm under nitrogen protection.

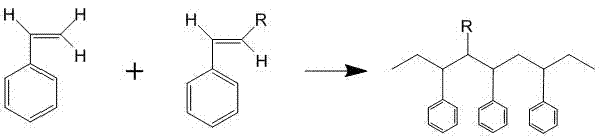

[0043] 4. Add 0.5-5g sodium dodecylsulfonate (SDS) as an emulsifier, 0.29-2.9g hydroxydicumyl peroxide (CHPO) and 0.23-2.3g tetraethylenepentamine to the reaction system in step 3 (TEPA) as oxidation-reduction initiator, 10mL DMSO solution of 5~50mmol styrene as reactant, pass into nitrogen (N 2 ), continuously stirred at a speed of 1000-5000rmp, and polymerized at 42°C for 2-4 hours.

[0044] 5. Centrifuge the obtained polymer at a rotational speed of 8000-10000 rpm, take the precipitate, wash with ...

Embodiment 2

[0051] Example 2 Preparation of Entity Fluorescent Nanospheres

[0052] 1. Dissolve 0.1g Rhodamine B in 200μL DMSO.

[0053] 2. Dissolve 0.1 g of phenylacetylene in 200 μL of DMSO, and then mix with Rhodamine B in DMSO.

[0054] 3. Add 5 mL of water to the reaction system, and stir for 2 hours at room temperature.

[0055] 4. Add 0.5g sodium dodecylsulfonate (SDS) to the reaction system as an emulsifier, 0.29g hydroxydicumyl peroxide (CHPO) and 0.23g tetraethylenepentamine (TEPA) as an oxidation-reduction initiator Agent, 0.5g styrene as reactant, pass N 2 , continuously stirred at 5000rmp, and polymerized at 42°C for 2h.

[0056] 5. The obtained polymer is washed with ethanol and then vacuum-dried to obtain the product.

Embodiment 3

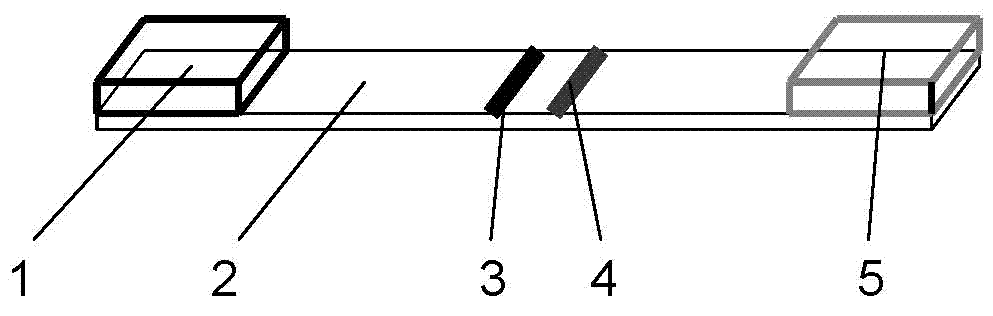

[0057] Example 3: Making an immunochromatographic detection reagent for solid fluorescent nanosphere NT-proBNP

[0058] 1. Labeled antibody:

[0059] (1) Take 0.5mL solid fluorescent nanospheres, centrifuge to get the precipitate, add MES buffer with pH 6.0 to wash twice.

[0060] (2) Activation: Add 200 μL of 50 mM carbodiimide (EDAC) and 200 μL of 50 mM hydroxysulfosuccinimide (Sulfo-NHS) to the washed microspheres, shake at room temperature for 2 h.

[0061] (3) Centrifuge the microspheres and wash twice with PBS.

[0062] (4) Add an appropriate amount of antibody and shake at room temperature for 2 hours.

[0063] (5) Centrifuge the microspheres, add 50mM glycine to quench the reaction, and shake at room temperature for 5 minutes; then centrifuge the microspheres, add 50mM glycine to completely quench the reaction, and shake at room temperature for 15 minutes.

[0064] ⑹ Centrifuge the microspheres, add blocking solution (1% BSA, 5% sucrose, 0.2% Tween-20, 0.1% sodium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com